Service hotline

+86 0755-83044319

release time:2025-05-08Author source:SlkorBrowse:1058

In today’s era of deep integration between smart technology and consumer electronics, the electric toy industry is undergoing a pivotal transformation from traditional mechanical drives to electronic and intelligent systems. From remote-controlled cars to smart robots, interactive story machines to programming education toys, the integration and complexity of electronic components have significantly increased. However, the highly integrated circuit systems have also introduced new challenges—electrostatic discharge (ESD) has become an invisible threat to product stability and user experience. Against this backdrop, the SLSOT05C ESD protection diode, with its precise electrical characteristics and compact design, has become the ideal solution for electrostatic protection in the electric toy sector.

Slkor Electrostatic Discharge Diode SLSOT05C product photo

Electric toys face multiple ESD risks during their usage:

Automated assembly equipment in the production process may generate static charge buildup.

Friction during transportation can cause packaging materials to carry a charge.

When children handle the toy’s surface, human static electricity (up to several thousand volts) can invade the circuit through buttons or interfaces. Without effective protection, ESD impacts could result in:

1. Component-level damage: Breakdown of microcontroller (MCU) pins, sensors, or wireless module inputs.

2. Functional abnormalities: Loss of memory data, distortion of communication module signals.

3. Lifespan degradation: Repeated ESD stress accelerates the degradation of the internal oxide layer in chips.

To meet the specific needs of electric toys, ESD protection devices must meet three core requirements:

Low clamping voltage: Ensures ESD energy is safely dissipated, avoiding over-voltage on subsequent circuits.

Low junction capacitance: Maintains the integrity of high-speed signals (e.g., Bluetooth, Wi-Fi).

Miniaturized packaging: Compatible with the compact PCB layout of toys.

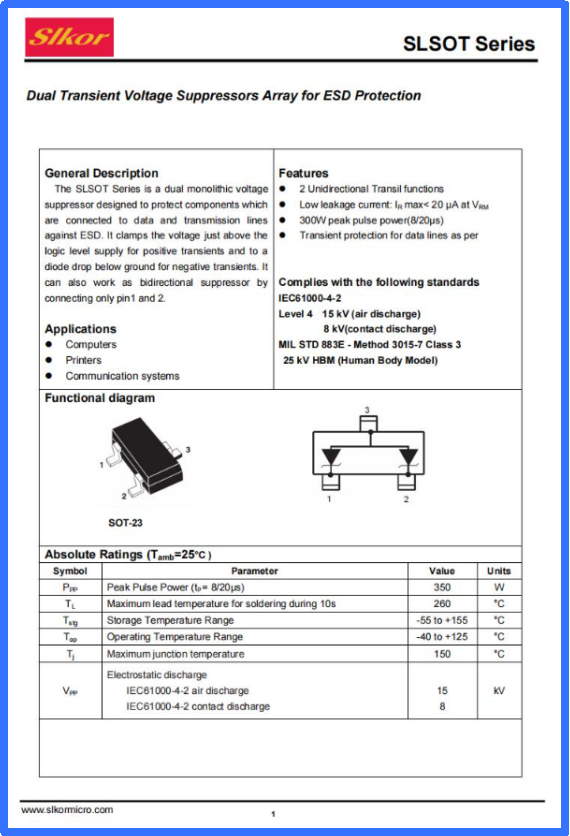

Slkor Electrostatic Discharge Diode SLSOT05C specification

The SLSOT05C, designed specifically for consumer electronics, perfectly aligns with the needs of electric toys. Key advantages include:

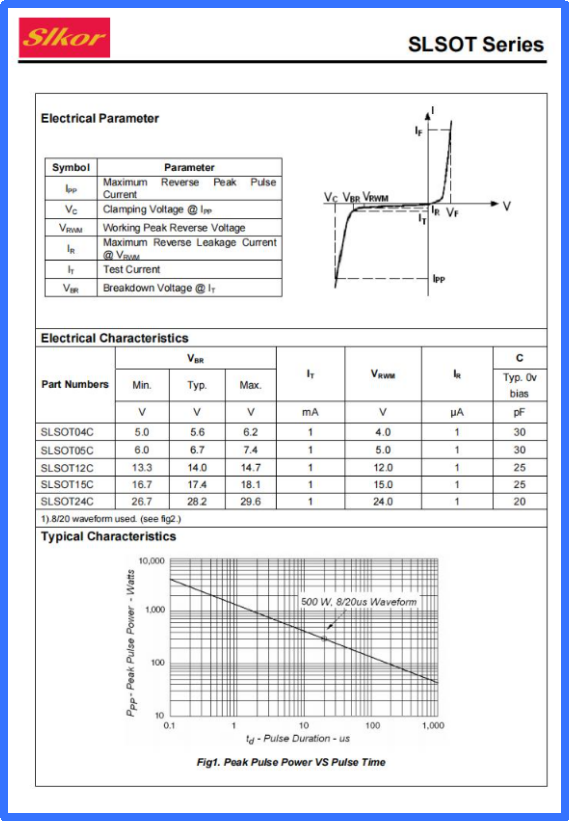

1. 5V Reverse Working Voltage (VRWM): A perfect match for lithium battery (3.7V) or alkaline battery (4.5V) power systems. In normal operation, it exhibits a high impedance state, without interference to the circuit.

2. 6V Breakdown Voltage (VBR min): When the ESD voltage exceeds 6V, the device quickly conducts to form a low-resistance path, preventing over-voltage stress on MCU pins.

3. 7.4V Clamping Voltage (VC): In IEC 61000-4-2 (contact discharge 8kV) tests, it limits the peak voltage to 7.4V, far below the absolute maximum rating of most CMOS devices (usually VDD+0.3V to VDD+2V).

4. 30pF Junction Capacitance (CJ): For 2.4GHz wireless modules (e.g., Bluetooth 5.0), the 30pF capacitance only causes a signal attenuation of about 0.5dB, ensuring that communication distance and data rate are unaffected.

Parameters of Slkor Electrostatic Discharge Diode SLSOT05C

1. Human-Machine Interface Protection

Modern electric toys commonly feature touch panels, physical buttons, or rotary encoders. The SLSOT05C can be deployed in:

Button matrix scanning lines: Prevents human static from injecting into the MCU GPIO through metal buttons.

Capacitive touch sensors: Protects the analog front end of dedicated touch chips (e.g., Cypress TrueTouch®).

USB/Type-C interfaces: Shields against electrostatic discharge during hot-plugging, extending the life of the interface.

2. Motor Driver Circuit Protection

Reverse electromotive force generated during DC motor commutation can cause ESD events via the H-bridge driver IC. The SLSOT05C can:

Be parallel to the PWM input of the motor driver IC, absorbing reverse voltage spikes.

Work with TVS diodes to form multi-level protection, keeping the clamping voltage within a safe threshold.

3. Wireless Communication Module Protection

2.4GHz/5GHz Wi-Fi and Bluetooth modules have stringent requirements for signal integrity. The SLSOT05C's 30pF low capacitance ensures:

RF link insertion loss (IL) is <0.8dB at 2.4GHz.

Maintains EVM (Error Vector Magnitude) specifications, ensuring data transmission rates (e.g., Bluetooth 5.0's 2Mbps mode) remain unaffected.

As electric toys evolve toward AI interaction and the Internet of Things (IoT), ESD protection demands will follow these trends:

1. Multi-channel integration: Single-chip integration of 4/6 ESD protection channels, simplifying PCB design.

2. Ultra-low dynamic resistance: Lowering clamping voltage further below 5V to match advanced process nodes.

3. Intelligent monitoring: Incorporating diagnostic functions to report ESD event frequency and intensity in real-time.

The SLSOT05C, as a benchmark product for current technology nodes, offers the best balance between performance and cost for electric toys, with its 5V working voltage, 30pF low capacitance, and SOT-23 packaging. Through precise electrostatic protection design, manufacturers can significantly enhance product reliability, reduce after-sales costs, and ultimately gain a competitive edge in the intense market landscape.

Slkor has research and development offices in Busan, South Korea, Beijing, China, and Suzhou, China. Most of the wafer manufacturing and packaging and testing are carried out within China. The company employs and collaborates with individuals and organizations worldwide, with a laboratory for product performance and reliability testing and a central warehouse located at its headquarters in Shenzhen. Slkor has filed for over a hundred invention patents, offers more than 2,000 product models, and serves over ten thousand customers globally. Its products are exported to countries and regions including Europe, the Americas, Southeast Asia, and the Middle East, making it one of the rapidly growing semiconductor companies in recent years. With well-established management systems and streamlined workflows, Slkor has rapidly enhanced the brand awareness and reputation of its "SLKOR" brand through its outstanding quality and standardized services. Its product range includes three major series: diodes, transistors, and power devices, with recent introductions of new products such as Hall elements and analog devices, expanding its presence in sensors, Risc-v microcontrollers, and other product categories.

Site Map | 萨科微 | 金航标 | Slkor | Kinghelm

RU | FR | DE | IT | ES | PT | JA | KO | AR | TR | TH | MS | VI | MG | FA | ZH-TW | HR | BG | SD| GD | SN | SM | PS | LB | KY | KU | HAW | CO | AM | UZ | TG | SU | ST | ML | KK | NY | ZU | YO | TE | TA | SO| PA| NE | MN | MI | LA | LO | KM | KN

| JW | IG | HMN | HA | EO | CEB | BS | BN | UR | HT | KA | EU | AZ | HY | YI |MK | IS | BE | CY | GA | SW | SV | AF | FA | TR | TH | MT | HU | GL | ET | NL | DA | CS | FI | EL | HI | NO | PL | RO | CA | TL | IW | LV | ID | LT | SR | SQ | SL | UK

Copyright ©2015-2025 Shenzhen Slkor Micro Semicon Co., Ltd