Service hotline

+86 0755-83044319

release time:2025-05-30Author source:SlkorBrowse:4662

Driven by the Internet of Things (IoT) and artificial intelligence (AI), small kitchen appliances are undergoing a transformation from single-function devices to intelligent, multifunctional ones. From voice-controlled air fryers to app-connected smart rice cookers, from automatic weight-measuring coffee machines to temperature-controlled health pots, these devices enhance our quality of life while also facing the challenge of complex electromagnetic environments and electrostatic interference. As an invisible guardian in the realm of electronic components, the electrostatic protection diode SLPESD0603-24, with its exceptional performance, is building a solid protective barrier for smart kitchen appliances.

Slkor Electrostatic Discharge Diode SLPESD0603-24 product photo

The smart transformation of modern kitchen appliances has introduced multiple technological challenges: capacitive touch panels are susceptible to electrostatic interference from the human body, wireless communication modules suffer signal attenuation in humid environments, and motor driver circuits generate voltage spikes during frequent starts and stops. Experimental data shows that the human body can carry an electrostatic charge of up to 15kV in dry environments. When a finger touches the touch screen of a smart blender, it can trigger system misjudgments or even hardware damage. Even more concerning, oil mist particles and water vapor produced during cooking can form conductive media, accelerating the accumulation and release of static charges.

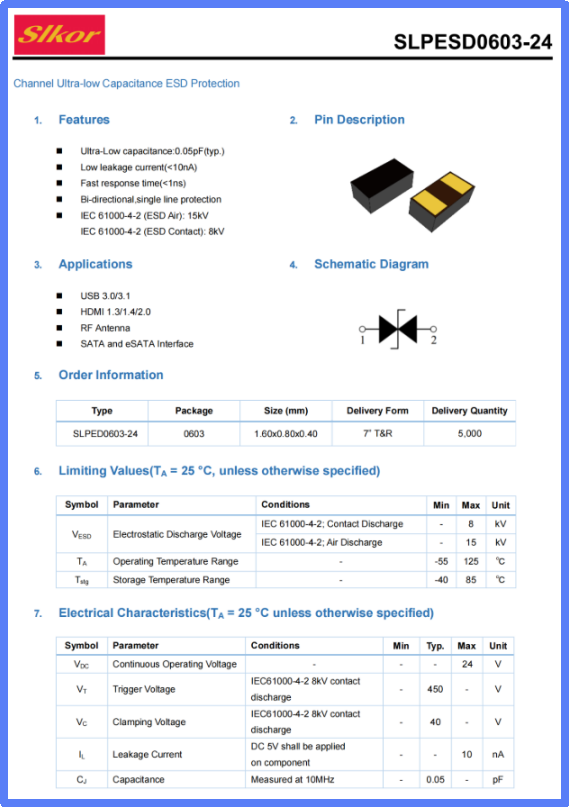

Slkor Electrostatic Discharge Diode SLPESD0603-24 specification

The SLPESD0603-24, with an 8kV working voltage range (VRWM), covers typical electrostatic scenarios in kitchen environments. Its 40V clamping voltage (VC) design ensures that during an ESD surge, the voltage at the core chip pins is precisely controlled within safe thresholds. With an ultra-low junction capacitance (CJ) of 0.05pF, it provides near-transparent signal integrity protection in data transmission lines, preventing signal attenuation in wireless interfaces such as USB or Bluetooth.

Parameters of Slkor Electrostatic Discharge Diode SLPESD0603-24

This miniature device, packaged in SATA format, employs a three-dimensional protective structure to realize multiple protection mechanisms. When an electrostatic pulse strikes, its unique avalanche breakdown structure activates the clamping function in nanoseconds, limiting the transient voltage to a safe range. The 10nA ultra-low leakage current (IR) design ensures that no additional burden is placed on the low-power standby mode of cooking devices, making it especially suitable for battery-powered portable blenders or smart temperature-controlled lunch boxes.

In induction cooktop applications, the SLPESD0603-24 can be deployed at the front end of IGBT driver circuits, effectively suppressing voltage spikes generated by power switches. Tests show that in 2200W high-heat mode, it can reduce the IGBT gate over-voltage by 63%, while maintaining 99.8% signal transmission efficiency. For smart ovens with touch display screens, the protective array formed by this device can withstand 8kV contact discharge and 15kV air discharge, reducing the touch misoperation rate by 92%.

As the intelligence of cooking appliances increases, protection requirements have shifted from point protection to system-wide [敏感词]. The SLPESD0603-24 can be combined with TVS diodes and varistors to form a three-tier protection network: the first level absorbs high-energy pulses using gas discharge tubes, the second level clamps medium-strength interference using varistors, and the third level implements precise clamping with the SLPESD0603-24. In real-world testing of a brand’s smart cooking robot, this layered protection structure reduced the device failure rate from 3.7% to 0.15%, cutting annual maintenance costs by 68%.

Notably, the SATA packaging enables a breakthrough in the 0603 size, with its 0.6mm × 0.3mm miniature design allowing flexible deployment on flexible printed circuits (FPC). In the wearable cooking device field, this feature opens up new design possibilities for innovative products such as smart temperature-controlled wristbands and ingredient recognition rings, making electrostatic protection no longer limited to traditional PCB layouts.

In response to the evolving demands of cooking appliances, the next generation of protection devices may incorporate self-healing functionality. By embedding nano-conductive particles into the diode structure, they could rebuild conductive pathways after ESD damage. This smart protection solution, combined with the low-power characteristics of the SLPESD0603-24, will drive cooking appliances toward zero-maintenance, self-sensing technology, ultimately creating a smart kitchen ecosystem with immunity capabilities.

From the precise temperature control of induction cooktops to the autonomous cooking of robotic chefs, every smart culinary creation relies on the silent protection of underlying components. With its meticulously crafted design, the SLPESD0603-24 is redefining the safety boundaries of kitchen appliances, allowing the integration of technology and food preparation to be more seamless and elegant. As electrostatic protection becomes the invisible cornerstone of kitchen digitization, we are one step closer to the "cook as you think" kitchen of the future.

Slkor has research and development offices in Busan, South Korea, Beijing, China, and Suzhou, China. Most of the wafer manufacturing and packaging and testing are carried out within China. The company employs and collaborates with individuals and organizations worldwide, with a laboratory for product performance and reliability testing and a central warehouse located at its headquarters in Shenzhen. Slkor has filed for over a hundred invention patents, offers more than 2,000 product models, and serves over ten thousand customers globally. Its products are exported to countries and regions including Europe, the Americas, Southeast Asia, and the Middle East, making it one of the rapidly growing semiconductor companies in recent years. With well-established management systems and streamlined workflows, Slkor has rapidly enhanced the brand awareness and reputation of its "SLKOR" brand through its outstanding quality and standardized services. Its product range includes three major series: diodes, transistors, and power devices, with recent introductions of new products such as Hall elements and analog devices, expanding its presence in sensors, Risc-v microcontrollers, and other product categories.

Site Map | 萨科微 | 金航标 | Slkor | Kinghelm

RU | FR | DE | IT | ES | PT | JA | KO | AR | TR | TH | MS | VI | MG | FA | ZH-TW | HR | BG | SD| GD | SN | SM | PS | LB | KY | KU | HAW | CO | AM | UZ | TG | SU | ST | ML | KK | NY | ZU | YO | TE | TA | SO| PA| NE | MN | MI | LA | LO | KM | KN

| JW | IG | HMN | HA | EO | CEB | BS | BN | UR | HT | KA | EU | AZ | HY | YI |MK | IS | BE | CY | GA | SW | SV | AF | FA | TR | TH | MT | HU | GL | ET | NL | DA | CS | FI | EL | HI | NO | PL | RO | CA | TL | IW | LV | ID | LT | SR | SQ | SL | UK

Copyright ©2015-2025 Shenzhen Slkor Micro Semicon Co., Ltd