Service hotline

+86 0755-83044319

release time:2025-08-01Author source:SlkorBrowse:925

Recently, the research team led by Professor Xu Huaping from the Department of Chemistry at Tsinghua University made significant progress in extreme ultraviolet (EUV) photoresist materials. They developed a novel photoresist based on polytelluoxane (PTeO), offering a new design strategy for key materials in advanced semiconductor manufacturing.

As integrated circuit processes advance towards the 7nm node and beyond, 13.5 nm wavelength EUV lithography has become the core technology enabling advanced chip manufacturing. However, characteristics of EUV light sources like high reflection loss and low brightness impose greater challenges on photoresists regarding absorption efficiency, reaction mechanisms, and defect control. Current mainstream EUV photoresists often rely on chemical amplification mechanisms or metal-sensitized clusters to enhance sensitivity but frequently face issues such as complex structures, uneven component distribution, easy diffusion of reactions, and the introduction of stochastic defects. Breaking through these bottlenecks to construct an ideal photoresist system is a core challenge in the current EUV lithography materials field. The academic community widely agrees that an ideal EUV photoresist should simultaneously possess the following four key elements: 1) High EUV absorption capacity to reduce exposure dose and improve sensitivity; 2) High energy utilization efficiency, ensuring light energy is efficiently converted into changes in photoresist material solubility within a small volume; 3) Molecular-scale uniformity to avoid defect noise caused by random component distribution and diffusion; 4) Minimal building units to eliminate the influence of elemental feature size on resolution and reduce line edge roughness (LER). For a long time, few material systems could meet all four criteria.

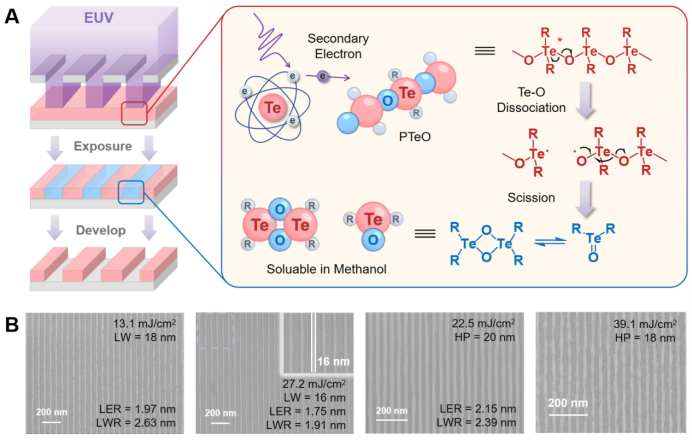

Professor Xu Huaping's research group developed a novel EUV photoresist based on their earlier invention of polytelluoxane, satisfying the conditions of the aforementioned ideal photoresist. In this study, the team directly incorporated tellurium (Te), a high-EUV-absorption element, into the polymer backbone via Te─O bonds. Tellurium possesses the highest EUV absorption cross-section among all elements except the inert gases xenon (Xe), radon (Rn), and the radioactive element astatine (At). Its EUV absorption capacity far exceeds that of short-period elements commonly used in traditional photoresists and metal elements like Zn, Zr, Hf, and Sn, significantly enhancing the EUV absorption efficiency of the photoresist. Simultaneously, the relatively low dissociation energy of the Te─O bond allows direct main chain scission upon EUV absorption, inducing solubility changes and enabling high-sensitivity positive-tone development. This photoresist is synthesized solely from single-component small molecules, integrating the characteristics of an ideal photoresist under an extremely simple design, providing a clear and feasible pathway for constructing next-generation EUV photoresists.

Polytelluoxane: The Ideal EUV Photoresist Material

This research provides a photoresist design path that integrates the high-absorption element Te, a main-chain scission mechanism, and material uniformity. It is expected to promote the development of next-generation EUV lithography materials and assist in the technological innovation of advanced semiconductor processes.

The related achievement was published in Science Advances on July 16th under the title "Polytelluoxane as the ideal formulation for EUV photoresist".

About SLKOR:

SLKOR, headquartered in Shenzhen, China, is a rapidly emerging national high-tech enterprise in the power semiconductor sector. With R&D centers in Beijing and Suzhou, its core technical team originates from Tsinghua University. As an innovator in silicon carbide (SiC) power device technology, SLKOR's products are widely used in new energy vehicles, photovoltaic power generation, industrial IoT, and consumer electronics, providing critical semiconductor solutions to over 10,000 clients globally.

The company delivers more than 2 billion units annually, with its SiC MOSFETs and 5th-generation ultrafast recovery SBD diodes setting industry benchmarks in efficiency ratio and thermal stability. SLKOR holds over 100 invention patents and offers 2,000+ product models, continually expanding its IP portfolio across power devices, sensors, and power management ICs. Certifications including ISO 9001, EU RoHS/REACH, and CP65 compliance demonstrate the company's steadfast commitment to technological innovation, lean manufacturing, and sustainable development.

Site Map | 萨科微 | 金航标 | Slkor | Kinghelm

RU | FR | DE | IT | ES | PT | JA | KO | AR | TR | TH | MS | VI | MG | FA | ZH-TW | HR | BG | SD| GD | SN | SM | PS | LB | KY | KU | HAW | CO | AM | UZ | TG | SU | ST | ML | KK | NY | ZU | YO | TE | TA | SO| PA| NE | MN | MI | LA | LO | KM | KN

| JW | IG | HMN | HA | EO | CEB | BS | BN | UR | HT | KA | EU | AZ | HY | YI |MK | IS | BE | CY | GA | SW | SV | AF | FA | TR | TH | MT | HU | GL | ET | NL | DA | CS | FI | EL | HI | NO | PL | RO | CA | TL | IW | LV | ID | LT | SR | SQ | SL | UK

Copyright ©2015-2025 Shenzhen Slkor Micro Semicon Co., Ltd