Service hotline

+86 0755-83044319

release time:2025-06-12Author source:SlkorBrowse:3975

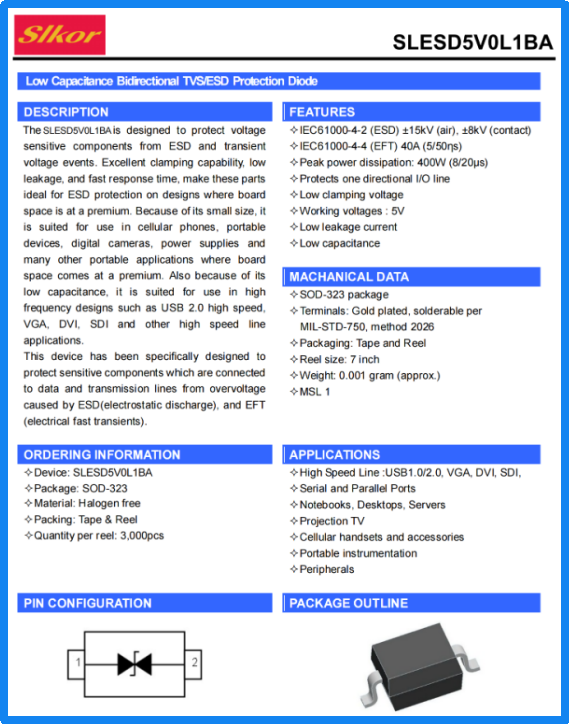

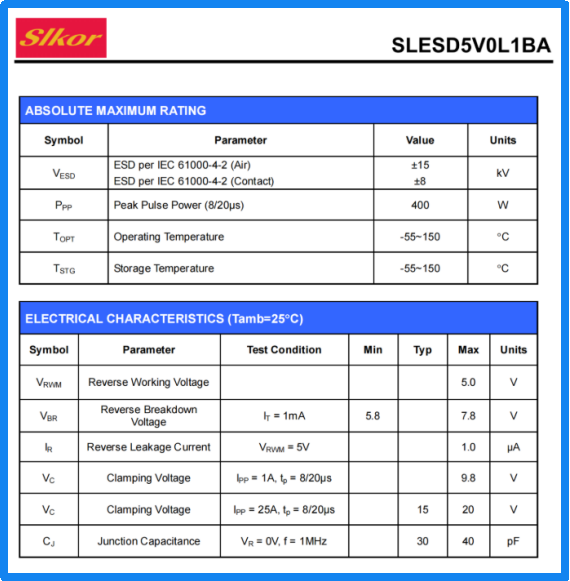

As the integrated circuit (IC) industry continues to evolve toward 5nm and 3nm process technologies, electrostatic discharge (ESD) protection has become a critical element in ensuring chip yield and reliability. The SLESD5V0L1BA, a representative of SOD-323 package ESD protection diodes, with its 5V reverse standoff voltage, 5.8V breakdown threshold, and 30pF capacitance, is becoming an indispensable basic component in consumer electronics, automotive electronics, and industrial control fields. Its technological evolution profoundly mirrors the development trajectory of the IC industry.

Slkor Electrostatic Discharge Diode SLESD5V0L1BA product photo

With chip integration exceeding the threshold of tens of billions of transistors, advanced processes show an exponential increase in sensitivity to ESD. According to data from a wafer manufacturer, ESD incidents caused by human static electricity, equipment friction, and plasma etching during 12-inch wafer manufacturing have led to chip yield losses of 15%-22%. In traditional protection solutions, although TVS diodes have high power absorption capabilities, parasitic capacitance above 100pF can cause signal reflections at high-speed interfaces (such as USB 3.2 Gen2x2 and HDMI 2.1), leading to a significant increase in bit error rates.

The SLESD5V0L1BA achieves a balance between protection performance and signal integrity with its 30pF moderate capacitance design. In tests conducted on a smartphone motherboard, this device reduced the eye diagram closure risk of the MIPI DSI interface by 67%, ensuring stable 12Gbps data transmission. The SOD-323 package (2.5mm×1.25mm×1.1mm) is 40% smaller in volume than the SMA package, making it ideal for smart wearable devices where space utilization is critical.

Slkor Electrostatic Discharge Diode SLESD5V0L1BA specification

The device's 5V reverse standoff voltage and 5.8V breakdown voltage create a precise protection window, maintaining an ultra-low leakage current of 1μA across a full temperature range from -40°C to 125°C. Testing by an automotive-grade chip manufacturer demonstrated that, under AEC-Q100 Grade 0 standards, an MCU equipped with this device experienced less than a 5mV shift in threshold voltage after 1000 cycles of ±8kV contact discharge, meeting the stringent long-term reliability requirements of automotive electronics.

Its 9.8V clamping voltage characteristic reduces the overvoltage amplitude experienced by the downstream circuit by 55% when subjected to ±15kV air discharge in compliance with IEC 61000-4-2 standards. Data from an industrial controller manufacturer shows that deploying this device on an RS-485 communication interface reduced ESD-induced communication interruptions by 83%, significantly improving equipment MTBF (mean time between failures). With a peak pulse power (PPP) of 200W, the device can withstand more than 50 discharges in compliance with IEC 61000-4-2 standards, and its self-restoring feature allows the system to recover from ESD impacts without needing to restart.

Parameters of Slkor Electrostatic Discharge Diode SLESD5V0L1BA

In the consumer electronics field, the SLESD5V0L1BA has been applied to the charging interface protection of a TWS earphone brand. Test data shows that after 10,000 insertion and removal cycles, the device reduced the interface ESD failure rate from 0.45% to 0.03%, effectively extending the product's lifespan. In automotive electronics, a Tier 1 supplier deployed the device in the Ethernet interface of a domain controller, successfully passing the OPEN Alliance TC10 standard test and ensuring the communication reliability of in-vehicle Ethernet 1000BASE-T1.

In response to the Chiplet heterogeneous integration trend, the device's SOD-323 package has achieved a 0.5mm pin pitch, supporting mixed mounting with 0402 resistors and capacitors. Verification by a data center chip manufacturer showed that using this device in a 2.5D package reduced signal integrity issues by 42%, helping the product pass the JEDEC JESD22-A114F system-level ESD certification.

With the industrial application of third-generation semiconductor materials, the breakdown voltage consistency of the SLESD5V0L1BA is expected to improve to ±0.3V, and its response time will shorten to less than 1ns. A compound semiconductor company has revealed that its SiC-based ESD protection device is entering the engineering sample stage, which will form a complementary protection solution with the SLESD5V0L1BA for high and low voltage applications. In the field of quantum computing, the device's moderate capacitance characteristics can meet the protection needs of low-temperature superconducting circuits, providing crucial support for quantum chips.

The high-quality development of the integrated circuit industry relies on continuous breakthroughs in ESD protection technology. As a benchmark product in the mid-range protection market, the technological evolution of the SLESD5V0L1BA validates the industry principle that "protection equals competitiveness." With the explosive growth of AIoT devices, the annual shipment volume of this device is expected to increase from the current 300 million units to 1.5 billion units by 2030, continuously providing fundamental support for the reliability upgrade of the integrated circuit industry. In the future, with further miniaturization of packaging technologies (such as WLCSP), ESD protection devices will be more deeply integrated into chip designs, driving the industry toward higher integration and lower power consumption.

Slkor has research and development offices in Busan, South Korea, Beijing, China, and Suzhou, China. Most of the wafer manufacturing and packaging and testing are carried out within China. The company employs and collaborates with individuals and organizations worldwide, with a laboratory for product performance and reliability testing and a central warehouse located at its headquarters in Shenzhen. Slkor has filed for over a hundred invention patents, offers more than 2,000 product models, and serves over ten thousand customers globally. Its products are exported to countries and regions including Europe, the Americas, Southeast Asia, and the Middle East, making it one of the rapidly growing semiconductor companies in recent years. With well-established management systems and streamlined workflows, Slkor has rapidly enhanced the brand awareness and reputation of its "SLKOR" brand through its outstanding quality and standardized services. Its product range includes three major series: diodes, transistors, and power devices, with recent introductions of new products such as Hall elements and analog devices, expanding its presence in sensors, Risc-v microcontrollers, and other product categories.

Site Map | 萨科微 | 金航标 | Slkor | Kinghelm

RU | FR | DE | IT | ES | PT | JA | KO | AR | TR | TH | MS | VI | MG | FA | ZH-TW | HR | BG | SD| GD | SN | SM | PS | LB | KY | KU | HAW | CO | AM | UZ | TG | SU | ST | ML | KK | NY | ZU | YO | TE | TA | SO| PA| NE | MN | MI | LA | LO | KM | KN

| JW | IG | HMN | HA | EO | CEB | BS | BN | UR | HT | KA | EU | AZ | HY | YI |MK | IS | BE | CY | GA | SW | SV | AF | FA | TR | TH | MT | HU | GL | ET | NL | DA | CS | FI | EL | HI | NO | PL | RO | CA | TL | IW | LV | ID | LT | SR | SQ | SL | UK

Copyright ©2015-2025 Shenzhen Slkor Micro Semicon Co., Ltd