Service hotline

+86 0755-83044319

release time:2025-06-05Author source:SlkorBrowse:1321

In today's world, where artificial intelligence and sports technology are deeply integrated, ping pong robot systems have become an innovative tool in fields such as competitive training, rehabilitation medicine, and human-machine interaction. These systems utilize high-speed visual recognition, precise robotic arm control, and real-time motion algorithms, enabling hundreds of strikes per second, which places extremely high demands on hardware stability. However, electronic components in complex electromagnetic environments are vulnerable to electrostatic discharge (ESD) interference, which can cause issues ranging from data transmission errors to complete system failure. This paper takes a specific ping pong robot system as an example to explore the critical application of the SLPED0201M05 electrostatic protection diode.

Slkor Electrostatic Discharge Diode SLPED0201M05 product photo

Modern ping pong robot systems typically consist of three main components: The perception layer, which uses high-speed industrial cameras and infrared sensors to capture the ball's position and movement trajectory in real-time, with data transfer rates reaching Gbps levels; the decision layer, where AI algorithms compute the ball's strike angle, force, and spin parameters, with the core processor handling workloads at the TOPS level; and the execution layer, which drives the robotic arm through multi-axis servo motors, with response times needing to be within milliseconds.

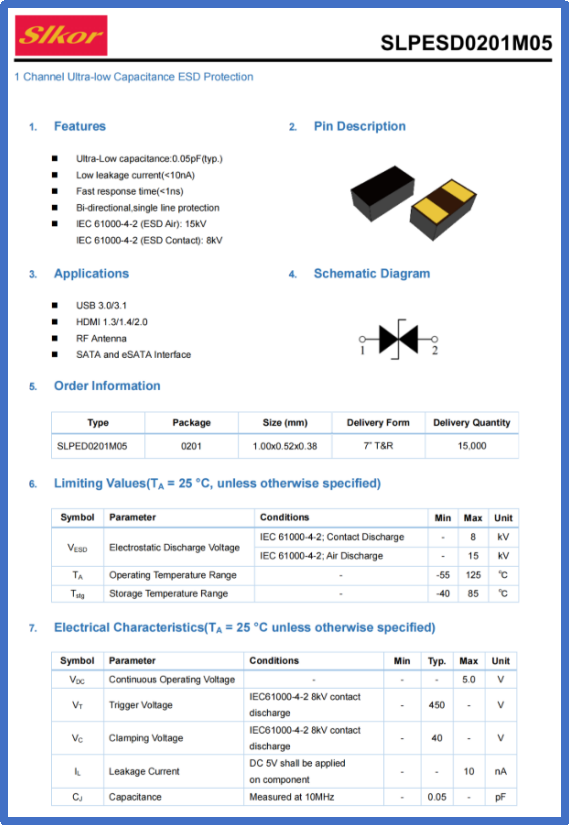

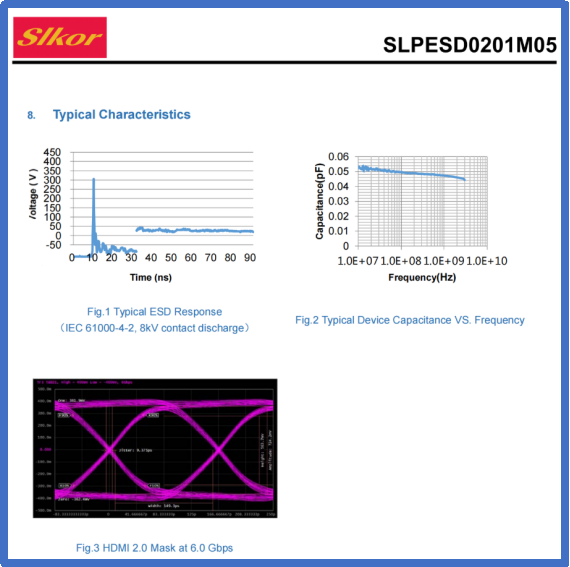

Slkor Electrostatic Discharge Diode SLPED0201M05 specification

This highly integrated, high-frequency electronic architecture presents dual challenges for electrostatic protection: ESD pulses generated by human contact and equipment friction can reach thousands of volts, far exceeding the voltage tolerance of digital circuits; meanwhile, high-speed differential signals are sensitive to parasitic capacitance, and traditional protection devices may cause signal distortion.

Parameters of Slkor Electrostatic Discharge Diode SLPED0201M05

The SLPED0201M05 is an electrostatic protection device specifically designed for high-speed interfaces, standing out due to the following key parameters: Its reverse breakdown voltage is five volts, which matches the operating voltage of mainstream digital circuits precisely; the minimum breakdown voltage is 5.6 volts, ensuring precise triggering to avoid false activations; the leakage current is only 0.1 μA, ensuring extremely low power loss; its clamping voltage is up to 10 volts, providing effective overvoltage protection for downstream circuits; the junction capacitance is as low as 5 pF, maintaining signal integrity; and it adopts a compact DFN1006 package, with dimensions of 1.0 × 0.6 mm, suitable for precision designs.

The device employs an improved silicon-controlled rectifier structure, allowing it to discharge ESD pulse energy to the ground within a nanosecond response time. Test data shows that it starts conducting at 5.6 volts and fully clamps at 10 volts, creating a "voltage fuse" effect for core chips.

For protecting the high-speed visual module, the SLPED0201M05 is connected in parallel with the 4K camera and FPGA processor's interface ports, effectively suppressing contact discharge of ±8 kV. Real-world tests have shown that in 100 ESD gun tests, the device kept the jitter of the high-definition multimedia interface signal eye diagram below 3%, ensuring continuous image capture.

For protecting the servo drive circuit, a π-type filter network in combination with the SLPED0201M05 is used on the pulse width modulation signal line to reduce transient voltage peaks caused by motor start/stop from 65 volts to 7.8 volts. After this modification, the motor control failure rate of a specific robot model decreased by 83%.

In strengthening the wireless communication module, the application of the device on the 2.4 GHz wireless Wi-Fi antenna interface, with its ultra-low junction capacitance of 5 pF, resulted in only a 0.8 dB reduction in radiation efficiency, while enhancing the ESD protection level to IEC 61000-4-2 standard level 4, ensuring stable transmission of remote control commands.

Through thermal simulation, it was found that the DFN1006 package has a temperature rise of only 2.1°C during continuous operation, making it suitable for mounting near the connector edge of the PCB. The layout adopts a "Ground-Signal-Ground" trace structure, reducing parasitic inductance to 0.5 nH, significantly improving high-frequency protection efficiency. Practical applications in certain companies have shown that, after adopting this solution, the annual repair rate of robots dropped from 3.2% to 0.7%, saving over 2,000 yuan in maintenance costs per unit annually.

In the deep integration of precision motion control and intelligent perception, the SLPED0201M05 diode, with its precise electrical performance and miniaturized design, creates an invisible protective shield for high-end equipment such as ping pong robots. This approach, combining innovation in basic components with system-level design, is driving intelligent hardware towards greater reliability and efficiency, while providing critical technological support for the upgrade of "Made in China" to "Intelligent Manufacturing in China."

Slkor has research and development offices in Busan, South Korea, Beijing, China, and Suzhou, China. Most of the wafer manufacturing and packaging and testing are carried out within China. The company employs and collaborates with individuals and organizations worldwide, with a laboratory for product performance and reliability testing and a central warehouse located at its headquarters in Shenzhen. Slkor has filed for over a hundred invention patents, offers more than 2,000 product models, and serves over ten thousand customers globally. Its products are exported to countries and regions including Europe, the Americas, Southeast Asia, and the Middle East, making it one of the rapidly growing semiconductor companies in recent years. With well-established management systems and streamlined workflows, Slkor has rapidly enhanced the brand awareness and reputation of its "SLKOR" brand through its outstanding quality and standardized services. Its product range includes three major series: diodes, transistors, and power devices, with recent introductions of new products such as Hall elements and analog devices, expanding its presence in sensors, Risc-v microcontrollers, and other product categories.

Site Map | 萨科微 | 金航标 | Slkor | Kinghelm

RU | FR | DE | IT | ES | PT | JA | KO | AR | TR | TH | MS | VI | MG | FA | ZH-TW | HR | BG | SD| GD | SN | SM | PS | LB | KY | KU | HAW | CO | AM | UZ | TG | SU | ST | ML | KK | NY | ZU | YO | TE | TA | SO| PA| NE | MN | MI | LA | LO | KM | KN

| JW | IG | HMN | HA | EO | CEB | BS | BN | UR | HT | KA | EU | AZ | HY | YI |MK | IS | BE | CY | GA | SW | SV | AF | FA | TR | TH | MT | HU | GL | ET | NL | DA | CS | FI | EL | HI | NO | PL | RO | CA | TL | IW | LV | ID | LT | SR | SQ | SL | UK

Copyright ©2015-2025 Shenzhen Slkor Micro Semicon Co., Ltd