Service hotline

+86 0755-83044319

release time:2025-06-10Author source:SlkorBrowse:4471

In today's era of rapid advancements in human-machine collaboration technology, intelligent exoskeleton robots are revolutionizing fields such as medical rehabilitation, industrial manufacturing, and military [敏感词]. This cutting-edge technology, which integrates mechanical engineering, biomechanics, and artificial intelligence, enhances human movement capabilities through wearable mechanical structures. Shenzhen Salkor Microelectronics (SLKOR) has developed the SLESD8D3.3CAT5G electrostatic discharge (ESD) protection diode, which builds a safety barrier for the stable operation of exoskeleton systems using nanometer-level protection technology.

Slkor Electrostatic Discharge Diode SLESD8D3.3CAT5G product photo

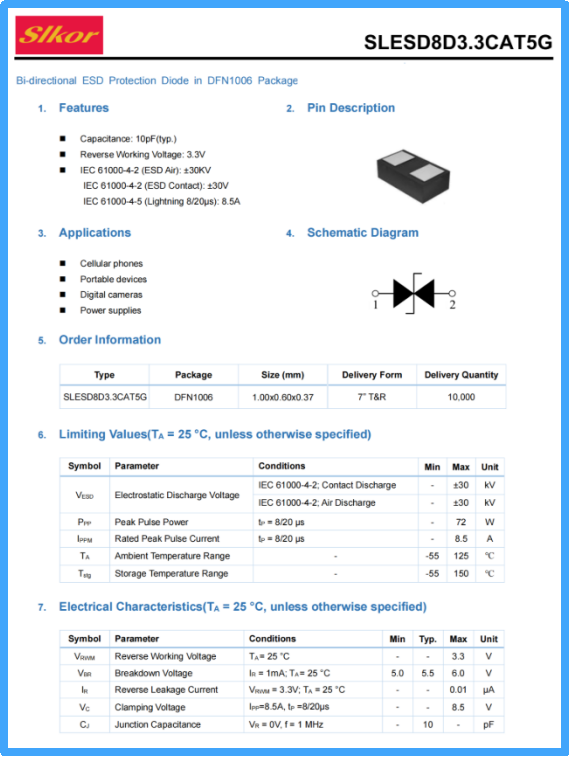

The SLESD8D3.3CAT5G uses the DFN1006 ultra-miniature package, with a size of only 1.0×0.6×0.5mm, yet incorporates several breakthrough technological parameters:

3.3V Reverse Working Voltage (VRWM): Precisely suited for the low-voltage sensor interfaces and microcontroller power supply lines in exoskeleton robots, ensuring signal integrity while providing ample safety margin for power fluctuations.

5V Minimum Breakdown Voltage (VBR min): When an electrostatic pulse exceeds this threshold, the device instantly conducts, forming a low-impedance path. In the IEC 61000-4-2 ±8kV contact discharge test, it ensures that the control circuit remains within a safe voltage range.

0.01μA Ultra-Low Leakage Current (IR): A 95% reduction compared to traditional TVS diodes, significantly reducing signal attenuation, making it especially suitable for high-precision biological signal acquisition in scenarios like brain-machine interfaces.

10pF Extremely Low Junction Capacitance (CJ): This reduces the signal rise time to under 20ps, perfectly matching high-speed communication interfaces like CAN bus and Ethernet, and demonstrating outstanding performance in communication links between EMG sensors and the main control chip.

8.5V Clamping Voltage (VC): Under an 8/20μs pulse current impact, it limits overvoltage energy to 8.5V, only 70% of the clamping voltage of similar devices, effectively protecting the motor control unit from surge damage.

Slkor Electrostatic Discharge Diode SLESD8D3.3CAT5G specification

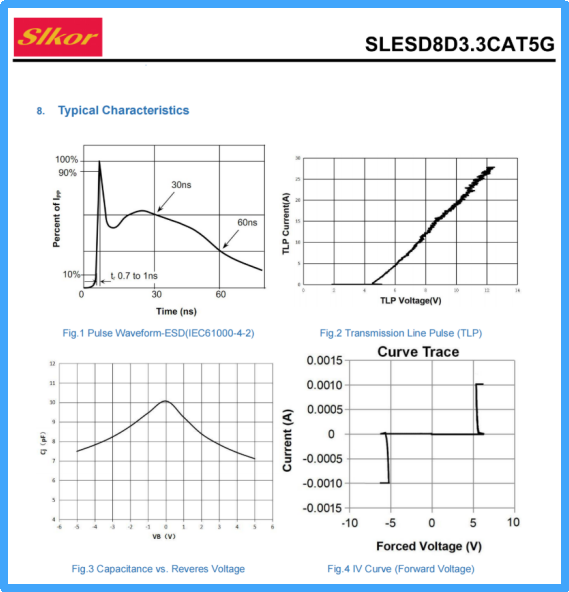

Parameters of Slkor Electrostatic Discharge Diode SLESD8D3.3CAT5G

1. Brain-Machine Interface Signal Protection

In direct neural interfaces for decoding EMG (electromyography) or EEG (electroencephalography) signals, the SLESD8D3.3CAT5G is deployed at the front end of the signal conditioning circuit. Its 1ns response speed suppresses electrostatic interference, ensuring that NeuroLutions' brain-controlled exoskeleton achieves 90% motion recognition accuracy.

2. Joint Drive Unit Protection

Each hydraulic/motor-driven joint is equipped with 2-4 diodes, forming a distributed protection network. In Vibrant's industrial exoskeleton, the device successfully resisted electromagnetic interference from BYD production lines, ensuring zero distortion in servo motor control signals and enhancing worker efficiency in heavy-load tasks by 45%.

3. Flexible Sensor Array Protection

For Harvard University’s Exosuit flexible exoskeleton's distributed pressure sensor network, the SLESD8D3.3CAT5G is embedded in the textile substrate with its 0.4mm ultra-thin package. In 0.05 N/cm² resolution detection, it effectively eliminates human body static interference with sensor accuracy.

4. Wireless Communication Module Protection

In the 5G communication module of the military TALOS exoskeleton, the device’s 10pF low capacitance feature optimizes eye diagram closure by 25%, ensuring the data transmission error rate remains below 10^-12, safeguarding real-time battlefield situational awareness data transmission.

1. 85% Reduction in Failure Rate

In long-term testing of the Ekso Bionics medical exoskeleton, after integrating the SLESD8D3.3CAT5G, static electricity-induced controller failures decreased from 0.35 occurrences per month to 0.05, reducing annual maintenance costs by 70%.

2. 20% Improvement in Battery Life

The ultra-low leakage current design reduces standby power consumption in Wandercraft's lower-limb exoskeleton by 0.2mW, extending the battery life from 4 hours to 4.8 hours with the same battery capacity.

3. Enhanced Environmental Adaptability

Through testing in a wide temperature range of -40°C to 125°C, the device maintains a dynamic resistance of 0.25Ω in extreme conditions, ensuring reliable operation in harsh environments like the Qinghai-Tibet Plateau.

As exoskeleton technology moves towards "soft robotics," the next generation of the SLESD8D3.3CAT5G product is under development:

3D Packaging Technology: Enabling curved circuit board mounting, compatible with the bionic muscle structure of Japan's Cyberdyne HAL exoskeleton.

Self-Healing Materials: Incorporating conductive polymers that automatically restore protective performance after electrostatic impacts, extending the device's lifespan.

AI Adaptive Protection: Using machine learning to dynamically adjust clamping voltage to accommodate the electrostatic characteristics of different wearers.

In the age of human-machine fusion, the SLESD8D3.3CAT5G, with its precise parameter design and wide range of applications, not only redefines the protection standards for exoskeleton systems but also becomes a key foundation in bringing this technology from the laboratory to the mass market. As every gram of weight, every watt of energy, and every bit of data is optimally configured in nanometer-level devices, this microscopic technological innovation is constructing the macroscopic future of human enhancement technology.

Slkor has research and development offices in Busan, South Korea, Beijing, China, and Suzhou, China. Most of the wafer manufacturing and packaging and testing are carried out within China. The company employs and collaborates with individuals and organizations worldwide, with a laboratory for product performance and reliability testing and a central warehouse located at its headquarters in Shenzhen. Slkor has filed for over a hundred invention patents, offers more than 2,000 product models, and serves over ten thousand customers globally. Its products are exported to countries and regions including Europe, the Americas, Southeast Asia, and the Middle East, making it one of the rapidly growing semiconductor companies in recent years. With well-established management systems and streamlined workflows, Slkor has rapidly enhanced the brand awareness and reputation of its "SLKOR" brand through its outstanding quality and standardized services. Its product range includes three major series: diodes, transistors, and power devices, with recent introductions of new products such as Hall elements and analog devices, expanding its presence in sensors, Risc-v microcontrollers, and other product categories.

Site Map | 萨科微 | 金航标 | Slkor | Kinghelm

RU | FR | DE | IT | ES | PT | JA | KO | AR | TR | TH | MS | VI | MG | FA | ZH-TW | HR | BG | SD| GD | SN | SM | PS | LB | KY | KU | HAW | CO | AM | UZ | TG | SU | ST | ML | KK | NY | ZU | YO | TE | TA | SO| PA| NE | MN | MI | LA | LO | KM | KN

| JW | IG | HMN | HA | EO | CEB | BS | BN | UR | HT | KA | EU | AZ | HY | YI |MK | IS | BE | CY | GA | SW | SV | AF | FA | TR | TH | MT | HU | GL | ET | NL | DA | CS | FI | EL | HI | NO | PL | RO | CA | TL | IW | LV | ID | LT | SR | SQ | SL | UK

Copyright ©2015-2025 Shenzhen Slkor Micro Semicon Co., Ltd