Service hotline

+86 0755-83044319

release time:2025-06-04Author source:SlkorBrowse:4462

Driven by the wave of intelligent and electric mobility, smart travel has become the core direction of global automotive industry transformation and upgrade. From the popularization of autonomous driving systems to the construction of connected car ecosystems, from the upgrade of in-car infotainment systems to the optimization of electric vehicle battery management systems, every technological innovation relies on the support of underlying electronic components. Among them, electrostatic protection diodes, as key components ensuring the stability of electronic devices, are building safety barriers for smart travel products with their precise protective capabilities. This article will take the RCLAMP0524P as an example to analyze how its technical parameters empower the smart mobility sector.

Slkor Electrostatic Discharge Diode RCLAMP0524P product photo

As vehicles evolve from mechanical tools to intelligent terminals, the complexity of in-car electronic systems has grown exponentially. Devices such as high-precision sensors relied on by autonomous driving systems, vehicle-to-everything (V2X) communication modules, and human-machine interaction screens all need to maintain stable operation in extreme environments. However, electronic components are vulnerable to electrostatic discharge (ESD) during manufacturing, transportation, and use, which can cause data transmission anomalies or even system failure in severe cases. According to statistics, more than 30% of electronic device failures are related to static electricity, a hidden danger particularly prominent in smart mobility scenarios.

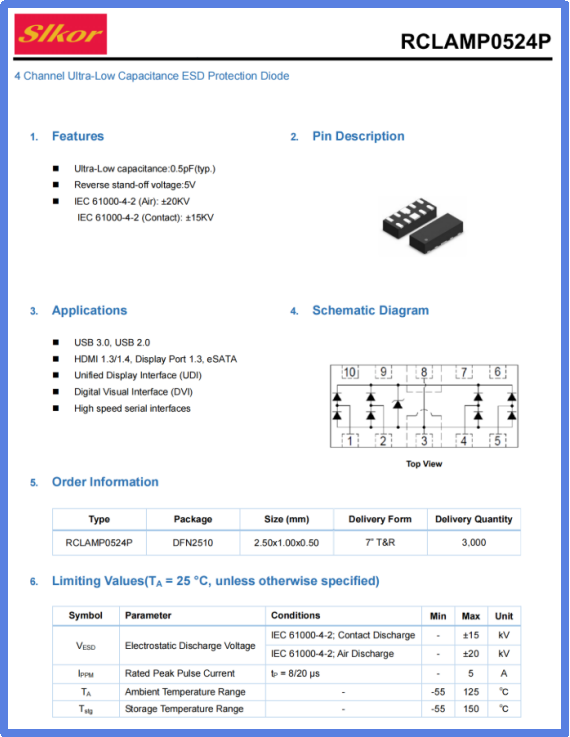

Slkor Electrostatic Discharge Diode RCLAMP0524P specification

Parameters of Slkor Electrostatic Discharge Diode RCLAMP0524P

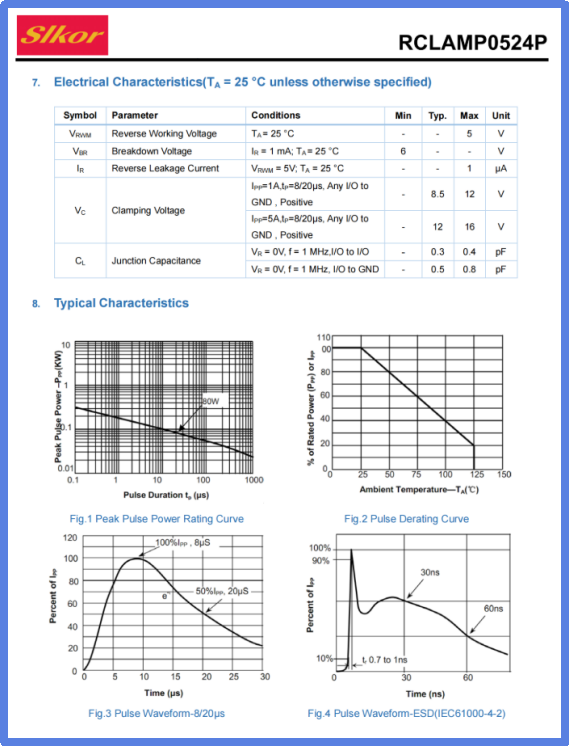

As an electrostatic protection diode specifically designed for high-speed interfaces, the RCLAMP0524P establishes a multi-dimensional protection system through key technical parameters:

1. Low Working Voltage and High Breakdown Threshold (VRWM=5V, VBR min=6V)

At a standard operating voltage of 5V, the device ensures signal integrity, while the minimum breakdown voltage of 6V offers quick response capability to transient overvoltage. This feature makes it ideal for low-voltage differential signal interfaces like in-vehicle USB and HDMI, effectively withstanding human body model (HBM) ±8kV and charged device model (CDM) ±1kV impacts.

2. Ultra-Low Leakage Current and Clamping Voltage (IR=1µA, VC=8.5V)

With a leakage current of just 1µA, the device's standby power consumption is nearly negligible, meeting the stringent low-power design requirements of electric vehicles. The 8.5V clamping voltage ensures that during an ESD event, overvoltage is precisely limited to a safe threshold, preventing damage to subsequent chips from voltage spikes.

3. Extremely Low Capacitance (CJ=0.4pF)

The minimal junction capacitance of 0.4pF has negligible impact on high-speed signal transmission and supports data transfer rates of up to 10Gbps. This feature makes it an ideal protective solution for high-speed interfaces such as in-vehicle Ethernet and MIPI cameras, ensuring real-time synchronization of radar and camera data in autonomous driving systems.

4. Miniaturized Packaging (DFN2510-10)

The compact 2.5mm × 1.0mm size with a 10-pin design allows easy integration into space-constrained vehicle PCBs, meeting the high-density layout requirements of smart cockpit multi-screen interactions and ADAS (Advanced Driver Assistance Systems) domain controllers.

- Autonomous Driving Domain Controller: In multi-sensor fusion systems, the RCLAMP0524P protects bus interfaces like CAN-FD and FlexRay, ensuring stable communication between LiDAR, millimeter-wave radar, and ECUs.

- Smart Cockpit System: For in-car central control screens, streaming rearview mirrors, and other touch-sensitive devices, its low capacitance characteristics ensure accurate touch signal acquisition while preventing damage to screen drive ICs caused by human electrostatic discharge during winter.

- V2X Communication Module: In DSRC or C-V2X communications between vehicles and roadside infrastructure (RSU), the device can withstand transient interference from complex electromagnetic environments, ensuring reliable communication links.

- Battery Management System (BMS): At the interface between high-voltage battery packs and low-voltage control units, the RCLAMP0524P prevents electrostatic discharge from maintenance operations, extending the lifespan of BMS chips.

As L3 and above autonomous driving becomes commercially viable, the requirements for electrostatic protection in automotive electronic systems will further increase. The next-generation products of RCLAMP0524P may break through in the following areas:

- Higher Integration: Reducing PCB footprint through multi-channel integration to adapt to zonal ECU architectures.

- Lower Clamping Voltage: Meeting the more stringent overvoltage protection needs of advanced process chips (e.g., below 5nm).

- Intelligent Protection Function: Integrating voltage monitoring and self-repair circuits to provide real-time feedback and dynamic adjustment of protection status.

As smart mobility moves from concept to reality, the technological breakthroughs of fundamental components like the RCLAMP0524P are pushing the boundaries of the industry in its role as an "invisible guardian." The leap from chip-level protection to system-level reliability is not only an advancement in electronics but also a profound response to the essential demand for "safe travel." In the future, with continuous innovation in material science and packaging technology, electrostatic protection technology will undoubtedly paint a safer picture for smart mobility.

Slkor has research and development offices in Busan, South Korea, Beijing, China, and Suzhou, China. Most of the wafer manufacturing and packaging and testing are carried out within China. The company employs and collaborates with individuals and organizations worldwide, with a laboratory for product performance and reliability testing and a central warehouse located at its headquarters in Shenzhen. Slkor has filed for over a hundred invention patents, offers more than 2,000 product models, and serves over ten thousand customers globally. Its products are exported to countries and regions including Europe, the Americas, Southeast Asia, and the Middle East, making it one of the rapidly growing semiconductor companies in recent years. With well-established management systems and streamlined workflows, Slkor has rapidly enhanced the brand awareness and reputation of its "SLKOR" brand through its outstanding quality and standardized services. Its product range includes three major series: diodes, transistors, and power devices, with recent introductions of new products such as Hall elements and analog devices, expanding its presence in sensors, Risc-v microcontrollers, and other product categories.

Site Map | 萨科微 | 金航标 | Slkor | Kinghelm

RU | FR | DE | IT | ES | PT | JA | KO | AR | TR | TH | MS | VI | MG | FA | ZH-TW | HR | BG | SD| GD | SN | SM | PS | LB | KY | KU | HAW | CO | AM | UZ | TG | SU | ST | ML | KK | NY | ZU | YO | TE | TA | SO| PA| NE | MN | MI | LA | LO | KM | KN

| JW | IG | HMN | HA | EO | CEB | BS | BN | UR | HT | KA | EU | AZ | HY | YI |MK | IS | BE | CY | GA | SW | SV | AF | FA | TR | TH | MT | HU | GL | ET | NL | DA | CS | FI | EL | HI | NO | PL | RO | CA | TL | IW | LV | ID | LT | SR | SQ | SL | UK

Copyright ©2015-2025 Shenzhen Slkor Micro Semicon Co., Ltd