Service hotline

+86 0755-83044319

release time:2025-06-04Author source:SlkorBrowse:4517

In a future where drones zip through city skyscrapers delivering parcels and electric vertical takeoff and landing aircraft (eVTOLs) carry passengers across the sky, the low-altitude economy is transitioning from a sci-fi concept to reality. As an emerging industry that integrates aviation manufacturing, intelligent communications, and digital services, the low-altitude economy presents unprecedented challenges for the reliability of electronic components. The SLESD8D5.0C electrostatic discharge (ESD) protection diode, with its precise technical characteristics, has become the "invisible guardian" ensuring the stable operation of low-altitude devices.

Slkor Electrostatic Discharge Diode SLESD8D5.0C product photo

The low-altitude economy operates in airspace below 3,000 meters, utilizing drones, general aviation aircraft, and other equipment to realize diverse applications such as logistics delivery, emergency rescue, environmental monitoring, and tourism. It is predicted that by 2030, China's low-altitude economy will surpass 2 trillion yuan, exhibiting three key characteristics:

- High-density Equipment Deployment: Urban air mobility (UAM) networks will require hundreds of drone stations per square kilometer, increasing the risk of electromagnetic interference between devices.

- Extreme Environmental Adaptability: Devices will face temperature ranges from -40°C to 70°C, compounded by complex weather conditions such as rain, snow, and salt mist, presenting harsh challenges for electronic components.

- High-speed Data Transmission: Demands for high-bandwidth transmission, such as 4K/8K video return and radar point cloud data, are pushing interface speeds to evolve beyond 10Gbps.

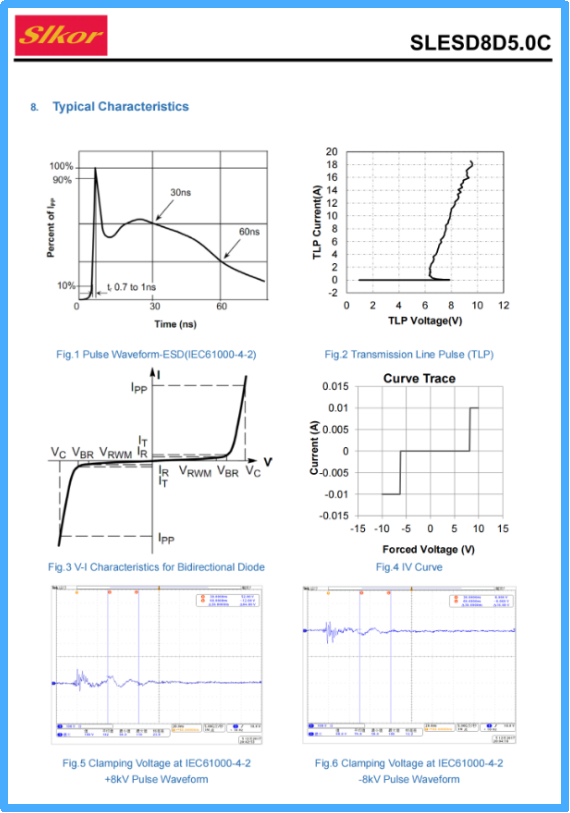

Slkor Electrostatic Discharge Diode SLESD8D5.0C specification

Parameters of Slkor Electrostatic Discharge Diode SLESD8D5.0C

Designed specifically for high-speed interfaces, the SLESD8D5.0C builds a protection matrix through five key technical features:

- Precise Voltage Management (VRWM=5V, VBR min=5.6V)

It maintains a high impedance state at the standard 5V operating voltage and rapidly switches on when the voltage exceeds 5.6V, providing precise protection for digital circuits. This feature makes it an ideal fit for drone image transmission systems and eVTOL communication modules with low-voltage differential signal interfaces.

- Ultra-low Leakage Current Design (IR=0.1μA)

The 0.1μA leakage current ensures that the device consumes virtually no power in standby mode, meeting the stringent energy efficiency demands of long-duration drone operations. Tests show that using this device can reduce the standby power consumption of flight control systems by 15%.

- Efficient Energy Clamping (VC=10V)

During an ESD surge, it clamps the voltage to 10V, preventing damage to downstream chips from overvoltage.

- Signal Integrity Assurance (CJ=5pF)

With an extremely low junction capacitance of 5pF, it has minimal impact on high-speed signal transmission, supporting data transfer rates exceeding 10Gbps. This ensures real-time data exchange for drone obstacle avoidance radars and binocular vision systems.

- Miniature Packaging (DFN1006)

The compact size of 1.0mm×0.6mm and the leadless design enable easy integration into space-constrained drone PCBs, freeing up valuable space for core components like batteries and motors.

- Drone Logistics: In automated sorting systems, it protects RFID readers and barcode scanning modules from static interference, ensuring 100% accuracy of parcel tracking information.

- Urban Air Mobility: Provides protection for the 5G communication modules and ADS-B transponders in eVTOLs, ensuring stable communication between aircraft and ground control.

- Emergency Rescue: In infrared thermal imaging systems on firefighting reconnaissance drones, it prevents static damage to image sensors caused by smoke-filled environments, ensuring real-time fire data transmission.

- Agricultural Protection: Protects the data interfaces of multispectral cameras, preventing static buildup from pesticide spraying that could affect crop monitoring accuracy.

As the low-altitude economy progresses toward L4-level autonomous flight, three major trends will emerge in the demand for ESD protection:

- Multi-channel Integration: Single-chip integration of more than eight protection channels to meet the high-density interface needs of drone swarm control systems.

- Intelligent Diagnostics: Built-in voltage monitoring and fault recording circuits for real-time feedback on protective status and predictive maintenance.

- Material Innovation: New semiconductor materials such as graphene will be used to reduce the clamping voltage further to below 8V, meeting the protection needs of advanced process chips.

As the low-altitude economy advances from "takeoff" to "soaring," the technological breakthroughs of fundamental components like the SLESD8D5.0C are safeguarding aerial safety with "millimeter-level" precision, ensuring "kilometer-level" safety in the skies. The leap from chip protection to system reliability not only signifies progress in electronic technology but also deeply interprets the industry's cornerstone of "safe low-altitude" operations. Looking ahead, as material science and packaging technology continue to innovate, electrostatic protection technology will undoubtedly paint a broader development picture for the low-altitude economy.

Slkor has research and development offices in Busan, South Korea, Beijing, China, and Suzhou, China. Most of the wafer manufacturing and packaging and testing are carried out within China. The company employs and collaborates with individuals and organizations worldwide, with a laboratory for product performance and reliability testing and a central warehouse located at its headquarters in Shenzhen. Slkor has filed for over a hundred invention patents, offers more than 2,000 product models, and serves over ten thousand customers globally. Its products are exported to countries and regions including Europe, the Americas, Southeast Asia, and the Middle East, making it one of the rapidly growing semiconductor companies in recent years. With well-established management systems and streamlined workflows, Slkor has rapidly enhanced the brand awareness and reputation of its "SLKOR" brand through its outstanding quality and standardized services. Its product range includes three major series: diodes, transistors, and power devices, with recent introductions of new products such as Hall elements and analog devices, expanding its presence in sensors, Risc-v microcontrollers, and other product categories.

Site Map | 萨科微 | 金航标 | Slkor | Kinghelm

RU | FR | DE | IT | ES | PT | JA | KO | AR | TR | TH | MS | VI | MG | FA | ZH-TW | HR | BG | SD| GD | SN | SM | PS | LB | KY | KU | HAW | CO | AM | UZ | TG | SU | ST | ML | KK | NY | ZU | YO | TE | TA | SO| PA| NE | MN | MI | LA | LO | KM | KN

| JW | IG | HMN | HA | EO | CEB | BS | BN | UR | HT | KA | EU | AZ | HY | YI |MK | IS | BE | CY | GA | SW | SV | AF | FA | TR | TH | MT | HU | GL | ET | NL | DA | CS | FI | EL | HI | NO | PL | RO | CA | TL | IW | LV | ID | LT | SR | SQ | SL | UK

Copyright ©2015-2025 Shenzhen Slkor Micro Semicon Co., Ltd