Service hotline

+86 0755-83044319

release time:2025-07-09Author source:SlkorBrowse:657

With the widespread use of electronic devices today, electrostatic discharge (ESD) has become one of the key threats to product reliability. From smartphones to industrial sensors, and from household appliances to IoT devices, various electronic systems may encounter ESD events during manufacturing, transportation, and usage. These events can range from causing performance degradation to permanently damaging the devices. Against this backdrop, ESD protection devices serve as the first line of [敏感词] for circuit protection, and their performance parameters and design compatibility directly affect the market competitiveness of products. Slkorhas launched the ESD protection diode PTVSHC2EN5VU, which, with its precise voltage characteristics, low-capacitance design, and compact package, provides an efficient electrostatic protection solution for low-speed interface devices and space-constrained applications.

The essence of electrostatic discharge is a high-voltage, short-duration energy shock, with peak currents reaching several amperes and durations as short as nanoseconds. For electronic circuits, this transient overvoltage can easily break down the PN junction of semiconductor devices, leading to functional failure. Therefore, ESD protection devices must have three core characteristics: fast response time, low clamping voltage, and voltage compatibility with the protected circuit.

The design of the PTVSHC2EN5VU reflects this logic. Its reverse working voltage (VRWM) is 6V, meaning that under normal operating conditions, the device remains in a high-impedance state for voltages below 6V and does not interfere with signal transmission. When an ESD event occurs, its breakdown voltage (VBR) minimum of 6.5V ensures that the device quickly conducts once the voltage exceeds the safety threshold, directing the overvoltage to the ground. At the same time, the clamping voltage (VC) of 8.5V is crucial — it indicates that under ESD stress, the device will limit the voltage to 8.5V, well below the breakdown threshold of most low-voltage circuits (e.g., CMOS devices typically have a breakdown voltage between 10-15V). This "precise clamping" characteristic effectively avoids secondary damage caused by high clamping voltages in traditional protection devices.

Signal integrity must also be considered in non-high-speed interface applications. Although the PTVSHC2EN5VU is not optimized for high-speed scenarios like HDMI or USB 3.0, its 650pF junction capacitance (CJ) still provides a significant advantage in low-speed interfaces. For example, in audio interfaces (such as 3.5mm headphone jacks), power management modules, or low-speed control buses (such as I²C or SPI), excessive capacitance can lead to signal attenuation or edge lag, while the 650pF capacitance ensures that signal transmission is virtually unaffected below 1MHz.

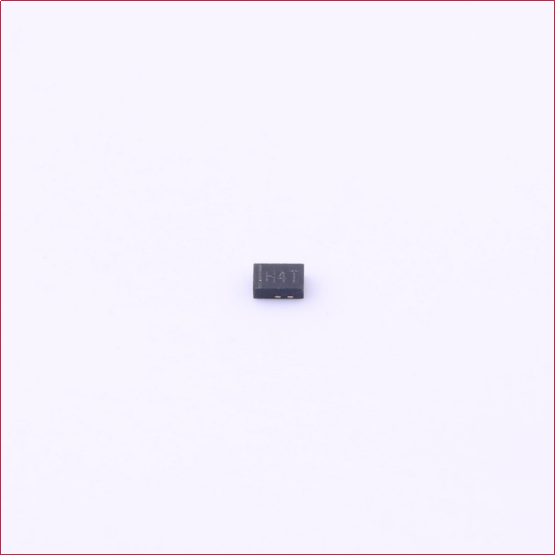

This feature is especially useful in space-constrained devices. Take smartwatches as an example — their motherboard area is typically less than 1 square inch but needs to integrate Bluetooth, sensors, charging interfaces, and other modules. The PTVSHC2EN5VU uses a DFN1610-2L package (dimensions 1.6mm×1.0mm, thickness 0.6mm), making it easy to embed in compact circuit layouts, while its low-capacitance characteristic prevents additional signal interference from protection devices, ensuring the accuracy of low-speed signals such as touch feedback and heart rate monitoring.

For battery-powered portable devices, leakage current (IR) is a crucial factor affecting standby time. The leakage current of the PTVSHC2EN5VU at 6V working voltage is only 1µA, which is leading in its class. For example, in true wireless earphones, their charging case needs to remain in standby mode for long periods. If each protection device has a leakage current of 1µA, the cumulative leakage current for 10 interfaces can reach 10µA. Based on a 3.7V lithium battery, the annual self-discharge loss would be approximately 0.32mAh. Although this value seems small, in the context of TWS earphones typically using 30-50mAh batteries, the cumulative effect will significantly shorten the replacement cycle. Saco Micro's low leakage current characteristic effectively alleviates this problem and helps devices achieve longer standby times.

As electronic devices evolve to be lighter, thinner, and smarter, the technological development of ESD protection devices shows two major trends: miniaturization of packaging and integration of performance. The DFN1610-2L package of the PTVSHC2EN5VU is a reflection of this trend, with an area about 60% smaller than the traditional SOT-23 package while maintaining the same level of electrical performance. In the future, as 5G and IoT become more widespread, the demand for ESD protection in low-speed interface devices will become more refined — requiring devices to have even lower capacitance and leakage current while achieving multi-channel integration in limited space.

Additionally, the upgrade of environmental regulations (such as RoHS and REACH) is driving ESD devices towards lead-free and high-temperature reliability. The PTVSHC2EN5VU meets lead-free processing requirements and has an operating temperature range of -55°C to 150°C, making it suitable for complex environments from the Arctic Circle to the tropics, providing a universal solution for devices in the global market.

SLKOR, headquartered in Shenzhen, China, is a rapidly emerging national high-tech enterprise in the power semiconductor sector. With R&D centers in Beijing and Suzhou, its core technical team originates from Tsinghua University. As an innovator in silicon carbide (SiC) power device technology, SLKOR's products are widely used in new energy vehicles, photovoltaic power generation, industrial IoT, and consumer electronics, providing critical semiconductor solutions to over 10,000 clients globally.

The company delivers more than 2 billion units annually, with its SiC MOSFETs and 5th-generation ultrafast recovery SBD diodes setting industry benchmarks in efficiency ratio and thermal stability. SLKOR holds over 100 invention patents and offers 2,000+ product models, continually expanding its IP portfolio across power devices, sensors, and power management ICs. Certifications including ISO 9001, EU RoHS/REACH, and CP65 compliance demonstrate the company's steadfast commitment to technological innovation, lean manufacturing, and sustainable development.

Site Map | 萨科微 | 金航标 | Slkor | Kinghelm

RU | FR | DE | IT | ES | PT | JA | KO | AR | TR | TH | MS | VI | MG | FA | ZH-TW | HR | BG | SD| GD | SN | SM | PS | LB | KY | KU | HAW | CO | AM | UZ | TG | SU | ST | ML | KK | NY | ZU | YO | TE | TA | SO| PA| NE | MN | MI | LA | LO | KM | KN

| JW | IG | HMN | HA | EO | CEB | BS | BN | UR | HT | KA | EU | AZ | HY | YI |MK | IS | BE | CY | GA | SW | SV | AF | FA | TR | TH | MT | HU | GL | ET | NL | DA | CS | FI | EL | HI | NO | PL | RO | CA | TL | IW | LV | ID | LT | SR | SQ | SL | UK

Copyright ©2015-2025 Shenzhen Slkor Micro Semicon Co., Ltd