Service hotline

+86 0755-83044319

release time:2025-06-17Author source:SlkorBrowse:4302

As electronic devices trend toward miniaturization and higher frequencies, electrostatic protection has become a crucial element in ensuring product reliability. The US1G, an electrostatic protection diode in an SMA package, demonstrates unique advantages across industrial control, communication devices, and consumer electronics, thanks to its core parameters: 400V reverse working voltage (VRWM), 1.25V clamping voltage (VC), and 17pF junction capacitance (CJ). This article explores its design logic from three perspectives: technical characteristics, application scenarios, and selection considerations.

Slkor Electrostatic Discharge Diode US1G product photo

With a VRWM of 400V, the US1G outperforms traditional TVS diodes, enabling it to handle high-voltage transient interference. In industrial power modules, this characteristic effectively absorbs surge voltages generated by relay switching or motor start/stop operations, preventing breakdowns in subsequent circuits. Its 1.25V clamping voltage strikes a balance between protective strength and signal integrity—under an 8/20µs pulse current surge, the US1G can limit voltage spikes to a safe range while maintaining a low on-resistance, minimizing signal attenuation.

Junction capacitance is a critical factor in assessing the impact of diodes on high-speed signals. The US1G’s 17pF junction capacitance is relatively low compared to similar products, allowing it to excel in high-speed interfaces such as USB 3.0 and HDMI 2.1. For example, in 4K video transmission, its low capacitance ensures that signal rise and fall times meet protocol requirements, preventing an increase in bit error rates due to parasitic capacitance. Additionally, its 5µA reverse leakage current (IR) ensures low power consumption during standby, meeting energy-saving demands in IoT devices.

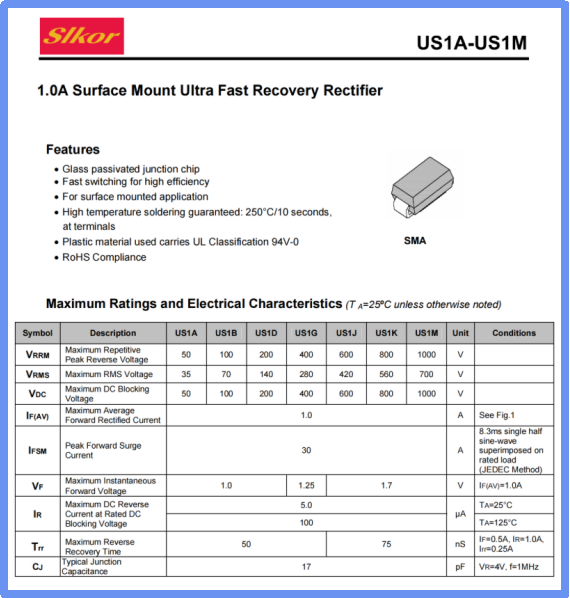

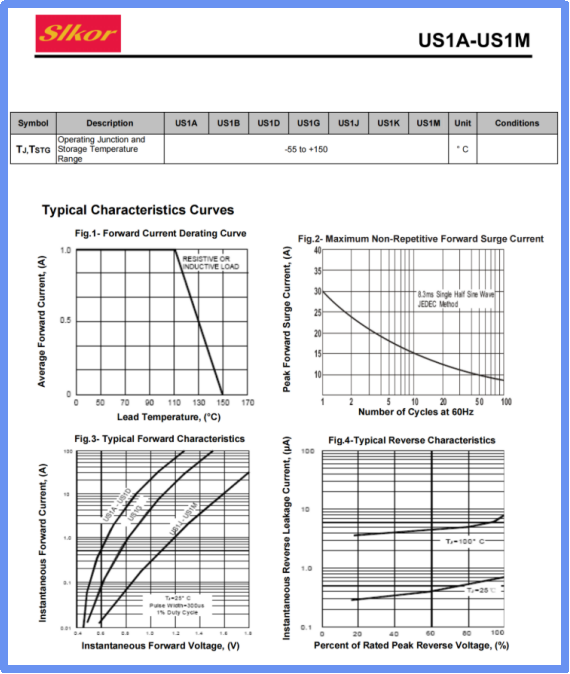

Slkor Electrostatic Discharge Diode US1G specification

Parameters of Slkor Electrostatic Discharge Diode US1G

In industrial automation, the US1G is commonly used for electrostatic protection in PLC input/output modules. Its SMA package can withstand 260°C/10-second high-temperature soldering, making it suitable for automated surface-mount assembly processes. In variable frequency drive (VFD) control circuits, the diode suppresses transient overvoltages generated by IGBT switching, protecting the drive chip from damage.

The communication equipment sector is another key application for the US1G. In 5G base station power modules, its 400V VRWM withstands transient high voltages caused by lightning strikes or power grid fluctuations, while its 17pF junction capacitance ensures the integrity of high-speed signals. In optical transceivers, the US1G can be paired with common-mode inductors to form a multi-stage protection system, meeting IEC 61000-4-2 Level 4 electrostatic discharge test standards.

In the consumer electronics field, where cost-performance balance is particularly important, the US1G is a great choice. In smart TV motherboards, it can replace multiple discrete components, simplifying PCB layouts. Its compact package (5.28mm×2.9mm×2.62mm) allows designers to achieve multi-path protection within limited space, such as simultaneously protecting HDMI, USB, and power interfaces.

When selecting the US1G, three key factors should be considered:

1. Voltage Matching: The VRWM should be at least 1.2 times higher than the maximum operating voltage of the circuit. For example, in a 220V AC/DC power supply, it’s recommended to choose a model with VRWM ≥ 600V to allow for a safety margin.

2. Signal Integrity: For high-speed interfaces above 10Gbps, choose a variant with a junction capacitance of ≤ 10pF, or employ a parallel filtering capacitor to compensate.

3. Thermal Design: In high-temperature environments (e.g., automotive electronics), consider the thermal resistance (RθJA = 88°C/W) to assess the heat dissipation requirements. Additional heat pads or thermal materials may be needed.

System-level protection designs should incorporate multi-stage protection architectures. For example, in automotive electronics CAN bus protection, the US1G can be placed in parallel at the interface as the first stage of protection, while a TVS diode can be added at the controller end as a second stage, forming a gradient clamping voltage to enhance overall protection performance.

With its 400V VRWM, 1.25V VC, and 17pF CJ, the US1G achieves an ideal balance between high voltage protection and signal integrity. As 5G, industrial IoT, and electric vehicles continue to grow, its application scenarios will expand. Designers must consider specific application needs, including parameter matching, package selection, and thermal design, to fully leverage the device’s performance advantages and build high-reliability electrostatic protection systems.

Slkor has research and development offices in Busan, South Korea, Beijing, China, and Suzhou, China. Most of the wafer manufacturing and packaging and testing are carried out within China. The company employs and collaborates with individuals and organizations worldwide, with a laboratory for product performance and reliability testing and a central warehouse located at its headquarters in Shenzhen. Slkor has filed for over a hundred invention patents, offers more than 2,000 product models, and serves over ten thousand customers globally. Its products are exported to countries and regions including Europe, the Americas, Southeast Asia, and the Middle East, making it one of the rapidly growing semiconductor companies in recent years. With well-established management systems and streamlined workflows, Slkor has rapidly enhanced the brand awareness and reputation of its "SLKOR" brand through its outstanding quality and standardized services. Its product range includes three major series: diodes, transistors, and power devices, with recent introductions of new products such as Hall elements and analog devices, expanding its presence in sensors, Risc-v microcontrollers, and other product categories.

Site Map | 萨科微 | 金航标 | Slkor | Kinghelm

RU | FR | DE | IT | ES | PT | JA | KO | AR | TR | TH | MS | VI | MG | FA | ZH-TW | HR | BG | SD| GD | SN | SM | PS | LB | KY | KU | HAW | CO | AM | UZ | TG | SU | ST | ML | KK | NY | ZU | YO | TE | TA | SO| PA| NE | MN | MI | LA | LO | KM | KN

| JW | IG | HMN | HA | EO | CEB | BS | BN | UR | HT | KA | EU | AZ | HY | YI |MK | IS | BE | CY | GA | SW | SV | AF | FA | TR | TH | MT | HU | GL | ET | NL | DA | CS | FI | EL | HI | NO | PL | RO | CA | TL | IW | LV | ID | LT | SR | SQ | SL | UK

Copyright ©2015-2025 Shenzhen Slkor Micro Semicon Co., Ltd