Service hotline

+86 0755-83044319

release time:2025-05-14Author source:SlkorBrowse:5038

With the increasing aging population and the growing demand for industrial automation, exoskeleton robots are moving from science fiction into real-world applications. These wearable devices, through the integration of sensors, actuators, and intelligent algorithms, provide rehabilitation support for people with mobility impairments or enhance lifting capabilities for industrial workers. However, highly integrated electronic systems in complex electromagnetic environments are susceptible to electrostatic discharge (ESD) threats, which can directly affect the stability and safety of the equipment. In this context, high-performance ESD protection devices have become a key guarantee for the reliability of exoskeleton robots. This paper uses the SLESD8D5.0CT5G electrostatic protection diode in SOT-23 packaging as an example to analyze how its technical characteristics enable precise protection for exoskeleton devices.

Slkor Electrostatic Discharge Diode SLESD8D5.0CT5G product photo

1. Sensor Data Distortion: Static electrical pulses couple onto analog signal lines, causing errors in position/force feedback.

2. Control Chip Locking: ESD surges can cause the MCU to reset or the program to malfunction, leading to movement stuttering.

3. Power Device Damage: High-voltage transients can break down MOSFETs or IGBTs, creating short-circuit risks.

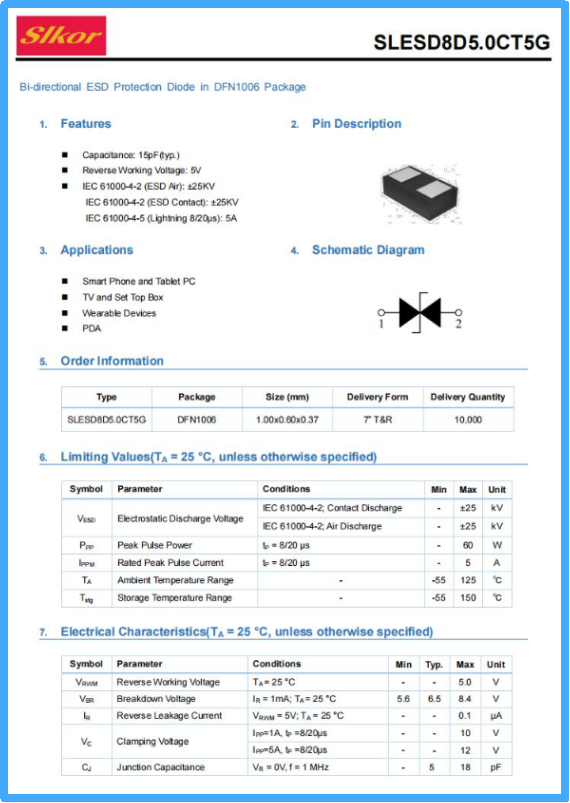

Slkor Electrostatic Discharge Diode SLESD8D5.0CT5G specification

1. Core Protection Specifications

VRWM=5V (Maximum Reverse Working Voltage): Suitable for common 3.3V/5V digital circuits in exoskeleton devices, ensuring no impact on signal integrity during normal operation.

VBR min=5.6V (Breakdown Voltage Lower Limit): When ESD voltage exceeds 5.6V, the diode conducts and dissipates the current, preventing overvoltage from reaching the subsequent circuit.

VC=10V (Clamping Voltage): In the IEC 61000-4-2 standard 8kV contact discharge test, the voltage is limited to 10V, well below the typical MCU breakdown threshold (usually 12-15V).

2. Dynamic Response Characteristics

IR=0.1μA (Reverse Leakage Current): Extremely low static power consumption (nanoampere level), ideal for battery-powered exoskeleton devices, extending battery life.

CJ=5pF (Junction Capacitance): Ultra-low capacitance design prevents signal attenuation, especially suitable for protecting high-speed communication interfaces (such as CAN bus, SPI), ensuring real-time transmission of control commands.

3. Packaging Advantages

DFN1006 Package (1.0mm×0.6mm): Miniaturized size suitable for high-density PCB layouts, leaving space for compact designs at exoskeleton joints, while meeting automated pick-and-place production needs.

Parameters of Slkor Electrostatic Discharge Diode SLESD8D5.0CT5G

1. Sensor Interface Protection

The force and angle sensors of the exoskeleton are connected to the main control board via flexible cables, which are easily affected by static interference from friction. The SLESD8D5.0CT5G can be connected in parallel between the signal line and ground to rapidly divert current during ESD events. Its 5pF capacitance ensures distortion-free transmission of analog signals (such as 0-10kHz EMG signals).

2. Wireless Communication Module Protection

The antenna port of Bluetooth/Wi-Fi modules is a weak point for ESD intrusion. The 10V clamping voltage of this device effectively suppresses overvoltage spikes in RF circuits, ensuring stable data transmission.

3. Power Path Protection

In the battery management unit (BMS), the SLESD8D5.0CT5G can be used in combination with TVS diodes to form multi-stage protection: the former absorbs transient energy, while the latter handles sustained overvoltage, prolonging battery life.

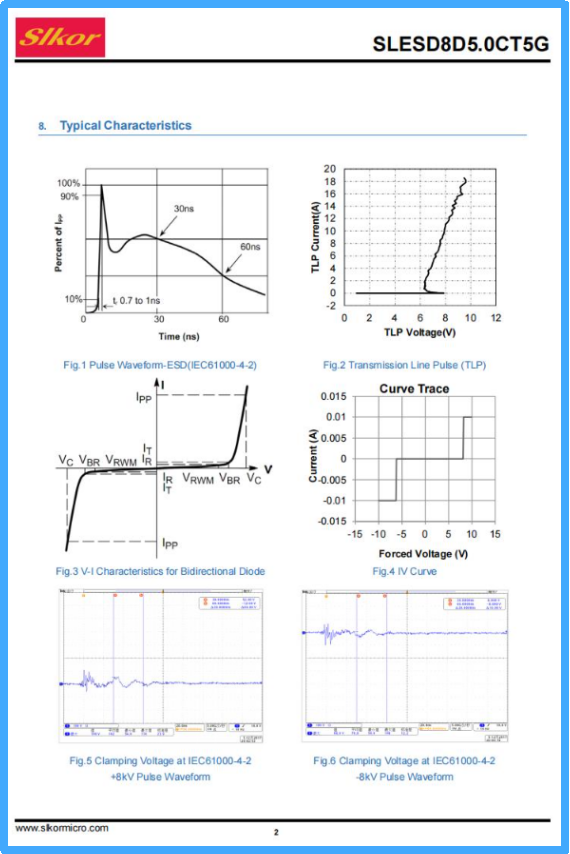

Through tests and certifications such as IEC 61000-4-2 (±8kV contact discharge/±15kV air discharge), ISO 10605 (automotive electronics standards), the SLESD8D5.0CT5G has proven its reliability in the following scenarios:

Ergonomics Testing: Simulating static electrical impacts during user wear/removal, with the device operating continuously for 1000 cycles without failure.

Industrial Environment Simulation: In an electromagnetic compatibility (EMC) chamber, the device passed the 10V/m RF radiation immunity test, with a control command error rate below 10⁻⁹.

The technological evolution of exoskeleton robots is shifting from "mechanical enhancement" to "intelligent sensing," with the stability of electronic systems as the cornerstone of this transition. The SLESD8D5.0CT5G electrostatic protection diode strikes a balance between miniaturization, low power consumption, and high reliability, providing invisible protection for medical rehabilitation robots and industrial assistive exoskeletons. As AIoT technology and flexible electronic materials continue to converge, such protective devices will evolve further, enabling human-machine collaboration devices to operate stably in even more demanding environments, ultimately realizing the vision of "technology empowering humanity."

Slkor has research and development offices in Busan, South Korea, Beijing, China, and Suzhou, China. Most of the wafer manufacturing and packaging and testing are carried out within China. The company employs and collaborates with individuals and organizations worldwide, with a laboratory for product performance and reliability testing and a central warehouse located at its headquarters in Shenzhen. Slkor has filed for over a hundred invention patents, offers more than 2,000 product models, and serves over ten thousand customers globally. Its products are exported to countries and regions including Europe, the Americas, Southeast Asia, and the Middle East, making it one of the rapidly growing semiconductor companies in recent years. With well-established management systems and streamlined workflows, Slkor has rapidly enhanced the brand awareness and reputation of its "SLKOR" brand through its outstanding quality and standardized services. Its product range includes three major series: diodes, transistors, and power devices, with recent introductions of new products such as Hall elements and analog devices, expanding its presence in sensors, Risc-v microcontrollers, and other product categories.

Site Map | 萨科微 | 金航标 | Slkor | Kinghelm

RU | FR | DE | IT | ES | PT | JA | KO | AR | TR | TH | MS | VI | MG | FA | ZH-TW | HR | BG | SD| GD | SN | SM | PS | LB | KY | KU | HAW | CO | AM | UZ | TG | SU | ST | ML | KK | NY | ZU | YO | TE | TA | SO| PA| NE | MN | MI | LA | LO | KM | KN

| JW | IG | HMN | HA | EO | CEB | BS | BN | UR | HT | KA | EU | AZ | HY | YI |MK | IS | BE | CY | GA | SW | SV | AF | FA | TR | TH | MT | HU | GL | ET | NL | DA | CS | FI | EL | HI | NO | PL | RO | CA | TL | IW | LV | ID | LT | SR | SQ | SL | UK

Copyright ©2015-2025 Shenzhen Slkor Micro Semicon Co., Ltd