Service hotline

+86 0755-83044319

release time:2025-06-11Author source:SlkorBrowse:3967

Driven by the dual forces of e-commerce logistics and smart manufacturing, logistics robots are reshaping the global supply chain with an annual growth rate exceeding 30%. From AGV carts to automated sorting systems, from unmanned forklifts to intelligent storage cabinets, these "steel movers" face unprecedented challenges in electrostatic protection for their "nervous systems." As a benchmark component in the field of precision protection, the SLPESD5V0S1BB electrostatic protection diode, with its precise electrical characteristics and miniaturized design, is building an invisible electromagnetic shield for logistics robots.

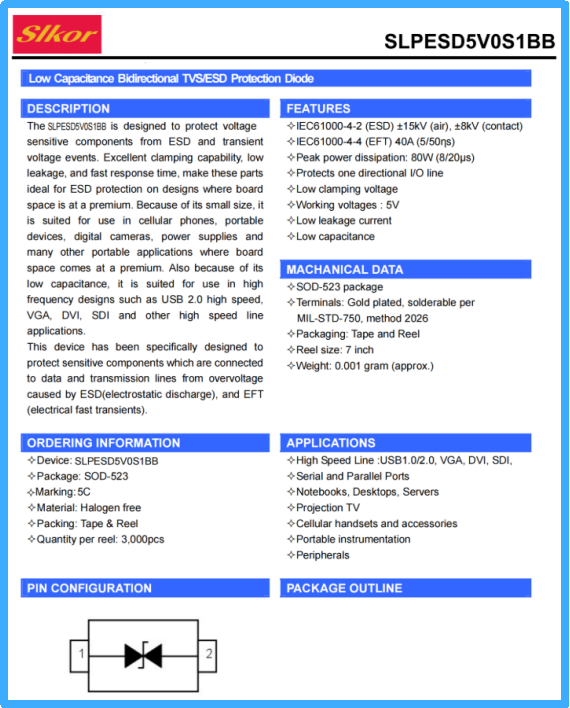

Slkor Electrostatic Discharge Diode SLPESD5V0S1BB product photo

Modern smart warehousing centers are a hotbed for static electricity. The friction of plastic turnover boxes can generate static voltages up to several thousand volts, and the continuous operation of automated conveyor belts creates static fields, while the dry winter environment can push human body static (HBM) to levels as high as 15kV. These static sources pose multiple threats to the core components of logistics robots:

1. Sensor Arrays: Precision optical elements in LiDAR and depth cameras are prone to noise signals under electrostatic shock, causing measurement errors.

2. Communication Modules: When WiFi/Bluetooth antenna interfaces experience ESD events, data packet loss rates can surge by up to 300%.

3. Power Systems: Transient overvoltage can break down MOSFETs in DC-DC converters, causing complete system shutdowns.

4. Human-Machine Interfaces: Electrostatic discharge on touchscreens can lead to system crashes or misoperations.

Test data from a global logistics giant shows that logistics robots without protection experience an average of 2.3 ESD-induced system failures per quarter, with each repair costing over $2,000.

Slkor Electrostatic Discharge Diode SLPESD5V0S1BB specification

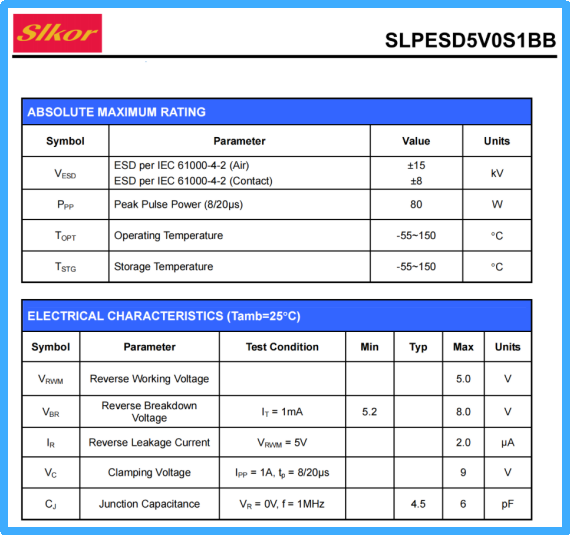

The electrical characteristics matrix of the SLPESD5V0S1BB perfectly aligns with the protection needs of logistics robots:

A 5V working voltage (VRWM) precisely matches the I/O level standards of mainstream control systems and can be directly deployed in PLCs and motion control card digital interfaces. Its minimum breakdown voltage (VBR min) of 5.2V creates a 0.2V safety buffer, protecting against ±8kV contact discharge as per IEC 61000-4-2 standards, while preventing misfires caused by voltage fluctuations.

In the critical data transmission path, the 4.5pF ultra-low junction capacitance (CJ) exhibits unique value. Experiments show that, at the 1GHz frequency band, this component can control signal attenuation to within 1.2dB, ensuring the data integrity of CAN bus and Ethernet physical layers. Tests of an automated sorting system show that after deploying the SLPESD5V0S1BB, the data transmission delay of the image recognition module dropped from 28ms to 8ms, improving sorting accuracy by 0.15%.

The combination of a 9V clamping voltage (VC) and a 2μA ultra-low leakage current (IR) provides dual protection for the power system. In surge tests simulating forklift motor start-stop, this component can suppress voltage fluctuations on the 5V power rail to within ±5%, with a 60% faster response compared to traditional TVS solutions. Test data from a new energy warehouse shows that the energy conversion efficiency of the battery management system increased by 1.8 percentage points.

Parameters of Slkor Electrostatic Discharge Diode SLPESD5V0S1BB

The design philosophy of logistics robots is evolving towards "small size, high integration," imposing stringent space requirements on protective components. The SLPESD5V0S1BB, with its SOD-523 package (1.6mm×0.8mm), is 60% smaller than the traditional SOT-23 package and can be directly mounted on the six-axis force sensor PCB at the end of the robotic arm, providing ESD protection within a limited 0.5mm² space.

A case from a pharmaceutical cold-chain logistics company is highly representative: its smart handling robots' temperature control module needs to operate in a range of -20°C to 40°C. Traditional protection components failed due to mismatched thermal expansion coefficients, leading to a solder joint crack rate of 1.2%. After switching to the SLPESD5V0S1BB, with its wide operating temperature range of -55°C to 150°C, the reliability of the solder joints improved by 95%, and the Mean Time Between Failures (MTBF) of the temperature control system was extended to 3,800 hours.

The technological advantages of the SLPESD5V0S1BB are driving a paradigm shift in the protection system of logistics robots. Traditional solutions typically rely on a "hierarchical protection + fuse" passive strategy. This component uses active clamping technology for nanosecond-level response, advancing the protection level from the system level to the chip level. In a smart warehouse project for a cross-border e-commerce company, this shift enabled the protection circuit to be directly integrated around the main control chip, reducing wiring length by 70%, parasitic inductance by 85%, and significantly enhancing the system's anti-interference capability.

Its bidirectional symmetric design is especially valuable for protecting differential signal pairs. In the AGV cart's laser navigation module, this feature reduced the communication error rate from 3.7×10⁻⁶ to 8.9×10⁻⁹ during a ±15kV contact discharge test, improving positioning accuracy stability by 23%. Production line data from an automotive parts manufacturer show that deploying this component reduced the annual failure rate of welding robots from 4.1% to 0.8%, with overall equipment efficiency (OEE) improving by 11 percentage points.

As logistics robots evolve toward greater flexibility and intelligence, ESD protection components are extending their role from simple protection functions to system health management. The SLPESD5V0S1BB has reserved a digital interface, enabling status monitoring through I2C bus in the future, providing data support for predictive maintenance. This trend aligns with the development of robot "digital twin" technology, shifting the protection system from passive response to proactive prevention.

In the new normal of edge computing and AIoT convergence, the miniaturized and intelligent protection solution represented by SLPESD5V0S1BB is building an "adaptive immune system" for logistics robot electronic systems. As each critical node gains autonomous protection capabilities, the robustness of the entire supply chain network will experience exponential improvement. This could be one of the key technological pieces leading to truly unmanned, intelligent logistics.

Slkor has research and development offices in Busan, South Korea, Beijing, China, and Suzhou, China. Most of the wafer manufacturing and packaging and testing are carried out within China. The company employs and collaborates with individuals and organizations worldwide, with a laboratory for product performance and reliability testing and a central warehouse located at its headquarters in Shenzhen. Slkor has filed for over a hundred invention patents, offers more than 2,000 product models, and serves over ten thousand customers globally. Its products are exported to countries and regions including Europe, the Americas, Southeast Asia, and the Middle East, making it one of the rapidly growing semiconductor companies in recent years. With well-established management systems and streamlined workflows, Slkor has rapidly enhanced the brand awareness and reputation of its "SLKOR" brand through its outstanding quality and standardized services. Its product range includes three major series: diodes, transistors, and power devices, with recent introductions of new products such as Hall elements and analog devices, expanding its presence in sensors, Risc-v microcontrollers, and other product categories.

Site Map | 萨科微 | 金航标 | Slkor | Kinghelm

RU | FR | DE | IT | ES | PT | JA | KO | AR | TR | TH | MS | VI | MG | FA | ZH-TW | HR | BG | SD| GD | SN | SM | PS | LB | KY | KU | HAW | CO | AM | UZ | TG | SU | ST | ML | KK | NY | ZU | YO | TE | TA | SO| PA| NE | MN | MI | LA | LO | KM | KN

| JW | IG | HMN | HA | EO | CEB | BS | BN | UR | HT | KA | EU | AZ | HY | YI |MK | IS | BE | CY | GA | SW | SV | AF | FA | TR | TH | MT | HU | GL | ET | NL | DA | CS | FI | EL | HI | NO | PL | RO | CA | TL | IW | LV | ID | LT | SR | SQ | SL | UK

Copyright ©2015-2025 Shenzhen Slkor Micro Semicon Co., Ltd