Service hotline

+86 0755-83044319

release time:2025-06-05Author source:SlkorBrowse:993

Driven by the wave of Industry 4.0, factory automation systems are rapidly evolving toward smarter, more interconnected, and faster solutions. From programmable logic controllers (PLCs) to multi-axis robotic arms, from industrial IoT sensors to 5G+TSN communication networks, modern factories have become integrated ecosystems of sophisticated electronic devices. However, in the complex electromagnetic environment and high-frequency on/off cycles of industrial sites, electrostatic discharge (ESD) incidents act as invisible threats, constantly jeopardizing system stability. This article focuses on the innovative application of the SLPESD0402M18 electrostatic protection diode in factory automation systems.

Slkor Electrostatic Discharge Diode SLPESD0402M18 product photo

Modern factory automation systems display three key characteristics:

1. High-speed Communication Networks: Industrial Ethernet, EtherCAT, and other bus systems with speeds exceeding 100 Mbps, with transmission distances of up to 100 meters per cable.

2. Precision Sensor Arrays: Laser radars and vision sensors with resolutions up to millions of pixels and sampling frequencies exceeding 10 kHz.

3. High-power Drive Units: Servo motors with peak currents reaching hundreds of amperes and IGBT modules with switching frequencies up to 20 kHz.

This technological architecture presents dual ESD threats:

- Direct Discharge Risk: ESD pulses from human contact can reach 15 kV, far exceeding the tolerance limits of digital chips.

- Indirect Coupling Interference: Transient voltages generated by inverters' start-stop cycles can propagate through power lines, with amplitudes reaching several hundred volts.

Test data from an automotive factory shows that without protective measures, the annual ESD failure rate of PLC modules is as high as 4.7%, with each downtime event causing losses of over 50,000 RMB.

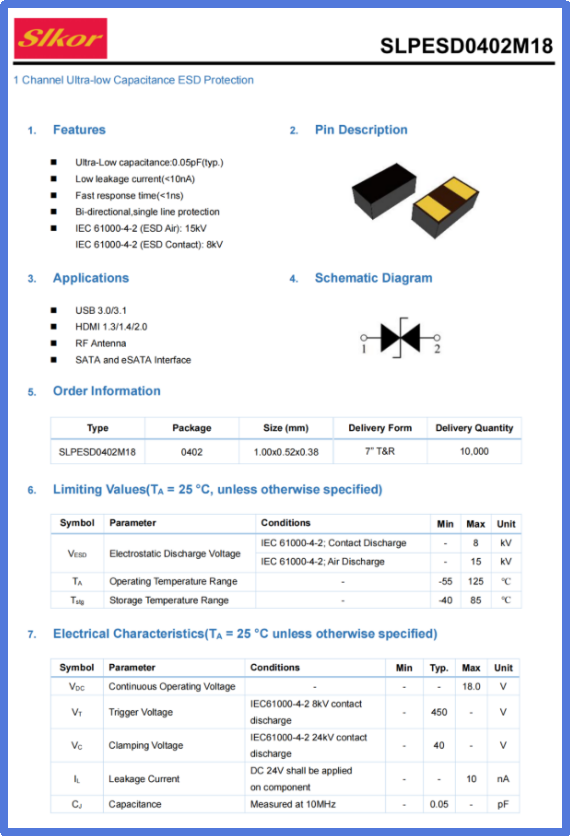

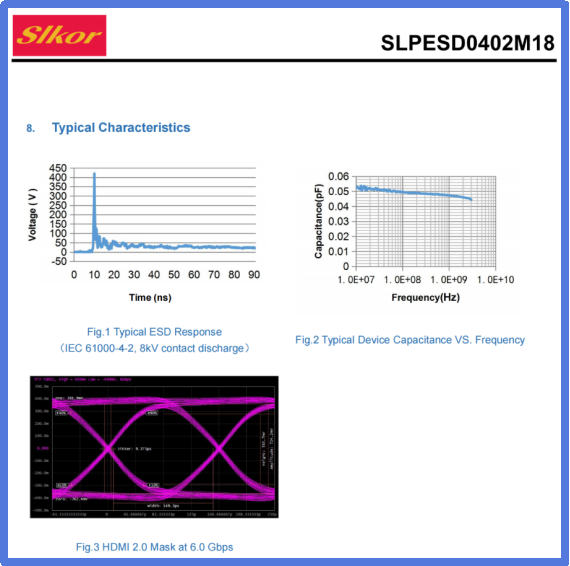

Slkor Electrostatic Discharge Diode SLPESD0402M18 specification

Parameters of Slkor Electrostatic Discharge Diode SLPESD0402M18

This electrostatic protection device, designed specifically for industrial environments, builds a protective barrier through four core parameters:

- VRWM (V): 18V

Matches the 24V industrial bus standard, providing non-intrusive protection for PLC I/O modules, RS-485 communication interfaces, and other applications. Tests show that the reverse breakdown voltage drift is less than ±2% within a temperature range of -40°C to 125°C.

- IR (A): 10nA

With an ultra-low leakage current design, the device's standby power consumption is only 0.18μW, making it ideal for solar-powered wireless sensor nodes. In a logistics sorting system, this increased battery life by 30%.

- VC (V): 40V

The clamping voltage is precisely controlled at 40V, suppressing ESD pulses while preventing excessive clamping that could damage subsequent circuits. In IEC 61000-4-5 surge testing, the device suppresses a 2kV pulse peak to a safe range.

- CJ (pF): 0.05pF

A groundbreaking reduction of junction capacitance to 0.05pF, 90% lower than traditional TVS diodes. Insertion loss at 100 MHz is only 0.2 dB, making it an ideal match for industrial Ethernet protocols like Profinet and CC-Link.

- 0402 Package Design (1.0×0.5mm)

Its miniaturized design allows it to be mounted in tight spaces between BGA pads on high-density PCBs, saving 30% layout space on industrial PC motherboards.

1. Industrial Robot Joint Protection

By paralleling the SLPESD0402M18 at the encoder interfaces of six-axis robotic arms, the system can withstand contact discharges up to ±8kV. Data from an electronics manufacturing plant shows that after the modification, the average annual downtime of robots decreased from 12 to 1, and the overall equipment efficiency (OEE) improved by 18%.

2. Reinforcing Intelligent Sensor Networks

For analog signal lines from vibration sensors and temperature-humidity sensors, a π-type filter network combined with this device increases common-mode interference suppression by 80 dB. The system successfully passed the 10V/m radiated immunity test in EMC testing.

3. 5G Industrial Gateway Protection

By deploying the SLPESD0402M18 at the antenna interface of 5G modules, its ultra-low capacitance of 0.05pF reduces signal attenuation to less than 0.3dB, while enhancing ESD protection to IEC 61000-4-2 Level 4, ensuring stable data links between AGV robots and cloud systems.

Thermal simulation reveals that the 0402 package experiences only a 1.8°C rise in temperature during continuous operation, allowing it to be mounted near IGBT module heat sinks. For optimal layout, a "ground-signal-ground" routing structure with 2 mil line width is used, reducing parasitic inductance to 0.3nH. After implementing this solution, a leading automotive electronics manufacturer successfully obtained AEC-Q100 Grade 1 automotive certification for their ECU controllers.

As industrial control precision advances to micrometer levels and communication delays are reduced to microseconds, the SLPESD0402M18 diode, with its precise electrical characteristics and miniaturized design, builds an invisible protective shield for factory automation systems. This integration of foundational component innovation with system-level design is driving smart manufacturing equipment toward greater reliability and efficiency, offering crucial technical support for China's "Made in China 2025" initiative. When each diode guards the nerve endings of a factory, what we witness is not only technological progress but also the solid footsteps of industrial civilization leaping toward a higher dimension.

Slkor has research and development offices in Busan, South Korea, Beijing, China, and Suzhou, China. Most of the wafer manufacturing and packaging and testing are carried out within China. The company employs and collaborates with individuals and organizations worldwide, with a laboratory for product performance and reliability testing and a central warehouse located at its headquarters in Shenzhen. Slkor has filed for over a hundred invention patents, offers more than 2,000 product models, and serves over ten thousand customers globally. Its products are exported to countries and regions including Europe, the Americas, Southeast Asia, and the Middle East, making it one of the rapidly growing semiconductor companies in recent years. With well-established management systems and streamlined workflows, Slkor has rapidly enhanced the brand awareness and reputation of its "SLKOR" brand through its outstanding quality and standardized services. Its product range includes three major series: diodes, transistors, and power devices, with recent introductions of new products such as Hall elements and analog devices, expanding its presence in sensors, Risc-v microcontrollers, and other product categories.

Site Map | 萨科微 | 金航标 | Slkor | Kinghelm

RU | FR | DE | IT | ES | PT | JA | KO | AR | TR | TH | MS | VI | MG | FA | ZH-TW | HR | BG | SD| GD | SN | SM | PS | LB | KY | KU | HAW | CO | AM | UZ | TG | SU | ST | ML | KK | NY | ZU | YO | TE | TA | SO| PA| NE | MN | MI | LA | LO | KM | KN

| JW | IG | HMN | HA | EO | CEB | BS | BN | UR | HT | KA | EU | AZ | HY | YI |MK | IS | BE | CY | GA | SW | SV | AF | FA | TR | TH | MT | HU | GL | ET | NL | DA | CS | FI | EL | HI | NO | PL | RO | CA | TL | IW | LV | ID | LT | SR | SQ | SL | UK

Copyright ©2015-2025 Shenzhen Slkor Micro Semicon Co., Ltd