Service hotline

+86 0755-83044319

release time:2025-06-06Author source:SlkorBrowse:4449

As the wave of Industry 4.0 sweeps across the globe, collaborative robots (Cobots) are reshaping production models with the core concept of “human-machine collaboration.” These intelligent devices, equipped with safety awareness and flexible deployment capabilities, are not only shining in fields like precision assembly and medical assistance but also becoming a key enabler for the digital transformation of small and medium-sized enterprises. However, one of the core challenges for collaborative robots is maintaining stable operation in complex electromagnetic environments. This article will take the electrostatic protection diode SEN0511D3 as an example to explore how its key parameters construct an "invisible shield" for the electronic systems of collaborative robots.

Slkor Electrostatic Discharge Diode SEN0511D3 product photo

Collaborative robots break the physical isolation limits of traditional industrial robots by achieving human-machine collaboration through force sensors, vision systems, and safety controllers. Take automotive electronics assembly as an example: collaborative robots can share workspace with engineers, precisely performing operations like circuit board insertion and screw fastening at micron-level precision. This “tough yet flexible” characteristic requires their control systems to have millisecond-level response capabilities and nanometer-level positioning accuracy, where the reliability of electronic components directly determines system stability.

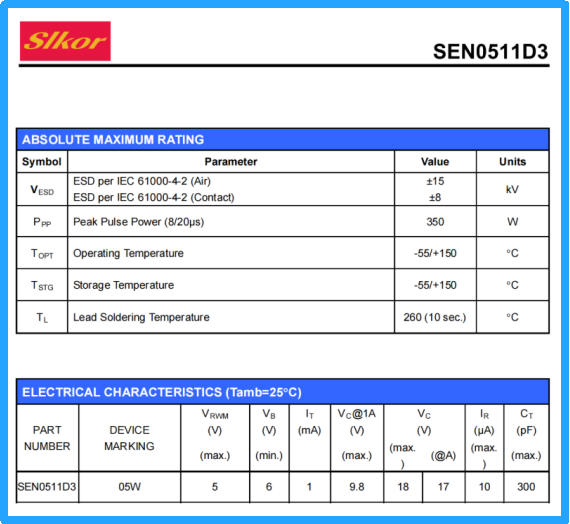

Slkor Electrostatic Discharge Diode SEN0511D3 specification

On automated production lines, phenomena such as plastic conveyor belt friction and human electrostatic discharge (ESD) create thousands of static shocks daily. For collaborative robots equipped with precision sensors and high-speed communication interfaces, transient overvoltage can lead to three major risks:

1. Data distortion: Signal distortion from CAN bus or Ethernet interfaces causing motion control commands to fail.

2. Component breakdown: Overvoltage damaging MOSFETs and IC chips, causing drive system failure.

3. Electromagnetic interference (EMI): ESD radiation affecting the image quality of vision recognition systems.

Parameters of Slkor Electrostatic Discharge Diode SEN0511D3

As an electrostatic protection device designed for high-speed interfaces, the SEN0511D3’s parameters perfectly meet the needs of collaborative robots:

1. Precise voltage clamping ability

- VRWM=5V: Maintains a high impedance state at the normal operating voltage of 5V, ensuring signal integrity.

- VBR min=6V: Initiates avalanche breakdown when voltage exceeds 6V for quick overvoltage discharge.

- VC=9.8V: Limits transient voltage to a safe threshold, preventing overvoltage damage to downstream circuits.

This stepwise protection mechanism acts like an "intelligent pressure relief valve" for the data bus, reducing voltage peaks by over 60% during ESD impacts.

2. Ultra-low parasitic effect design

- CJ=300pF: The extremely low junction capacitance ensures signal edge rates are unaffected.

- SOD-323 small package: Can be densely deployed at each I/O port in the 0.2㎡ robot control cabinet.

Test data shows that at a communication frequency of 100 MHz, signal attenuation caused by SEN0511D3 is less than 0.5dB, fully meeting the transmission requirements of industrial buses like EtherCAT and Profinet.

3. Extreme environment adaptability

- IR=10µA: Microamp-level reverse leakage current ensures long-term operational stability.

- Operating temperature range of -55°C to 150°C, suitable for high-temperature environments like soldering workshops.

In a practical test at an automotive electronics factory, a collaborative robot equipped with SEN0511D3 operated for 18 months without ESD failures, achieving an 8-fold increase in MTBF (Mean Time Between Failures) compared to unprotected systems.

In the joint modules of collaborative robots, the SEN0511D3 can be deployed in:

1. Servo drive interfaces: Protect encoder signal lines from voltage spikes during motor starts and stops.

2. End-effector interfaces: Provide ESD protection for actuators such as pneumatic grippers and electric screwdrivers.

3. Human-machine interaction interfaces: Safeguard the signal integrity of touch screens, emergency stop buttons, and other operation units.

A practice from a 3C electronics manufacturer demonstrated that after adopting this device in a cluster of 200 collaborative robots, annual maintenance costs were reduced by 42%, and production line utilization increased to 98.6%.

With the development of AI technology, the next generation of electrostatic protection devices will integrate self-diagnosis functions:

- Real-time monitoring of ESD event counts and energy levels via I2C interface.

- Predictive maintenance by combining machine learning to forecast component lifespans.

- Dynamic adjustment of clamping voltage to adapt to different operating modes.

SEN0511D3, as a benchmark product in protection technology, is leading the industry toward the evolution of “active protection + smart management.”

In the flexible manufacturing network built by collaborative robots, electrostatic protection devices like the SEN0511D3 act like the "myelin sheath" of the nervous system, safeguarding the smooth flow of data with nanosecond-level response. As Chinese manufacturing transitions to “precision smart manufacturing,” this extreme pursuit of detail will ultimately drive the powerful momentum of industrial upgrades.

Site Map | 萨科微 | 金航标 | Slkor | Kinghelm

RU | FR | DE | IT | ES | PT | JA | KO | AR | TR | TH | MS | VI | MG | FA | ZH-TW | HR | BG | SD| GD | SN | SM | PS | LB | KY | KU | HAW | CO | AM | UZ | TG | SU | ST | ML | KK | NY | ZU | YO | TE | TA | SO| PA| NE | MN | MI | LA | LO | KM | KN

| JW | IG | HMN | HA | EO | CEB | BS | BN | UR | HT | KA | EU | AZ | HY | YI |MK | IS | BE | CY | GA | SW | SV | AF | FA | TR | TH | MT | HU | GL | ET | NL | DA | CS | FI | EL | HI | NO | PL | RO | CA | TL | IW | LV | ID | LT | SR | SQ | SL | UK

Copyright ©2015-2025 Shenzhen Slkor Micro Semicon Co., Ltd