Service hotline

+86 0755-83044319

release time:2025-06-06Author source:SlkorBrowse:4684

In the era of the Internet of Things, Bluetooth technology, with its low power consumption and high compatibility, has penetrated fields such as smart wearables, smart homes, and healthcare. From TWS headphones to body fat scales, from in-car central control systems to industrial sensors, Bluetooth devices are reshaping the way people live through "wireless" connectivity. However, with the trend toward miniaturization and integration, the sensitivity of Bluetooth modules to electrostatic discharge (ESD) has become increasingly prominent. This article takes the SM03 electrostatic protection diode as an example to explain how it forms an "invisible barrier" for Bluetooth devices.

Slkor Electrostatic Discharge Diode SM03 product photo

Bluetooth technology enables short-range data transmission through the 2.4 GHz frequency band. Its core advantages include:

1. Ultra-low power consumption: Under the BLE 5.0 standard, a button battery can power a device for several years.

2. Flexible networking: It supports role switching between master and slave devices, allowing for the construction of a Mesh self-network.

3. Adaptability to multiple scenarios: From Kbps-level sensor data to Mbps-level audio streams, Bluetooth can handle various types of data transmission.

For example, a smartwatch’s Bluetooth module must simultaneously connect to a phone, headphones, and health monitoring sensors, while also resisting sweat corrosion and friction-induced electrostatic in athletic environments. This "always-on" characteristic demands that the circuit design maintain both signal integrity and environmental adaptability.

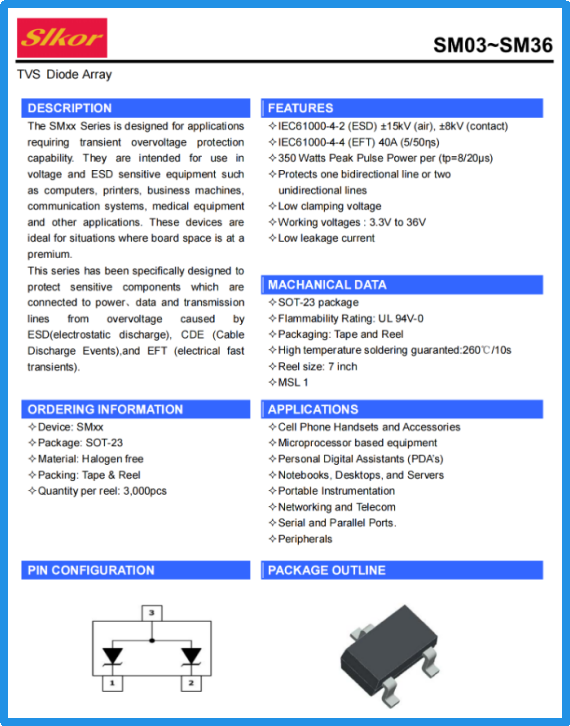

Slkor Electrostatic Discharge Diode SM03 specification

Throughout the production, transportation, and use of Bluetooth devices, electrostatic hazards are ever-present:

Production phase: Static electricity generated by friction between the pick-and-place nozzle and components during SMT can reach kilovolt levels.

Usage scenarios: Contact with the device by the human body can generate up to 8kV contact discharge or 15kV air discharge.

Special environments: In dry climates, electrostatic accumulation can occur from friction between devices.

For Bluetooth chips, which operate at a voltage of only 3.3V, transient overvoltages pose three main risks:

1. Degraded RF performance: ESD interference can cause Bluetooth signal modulation distortion and intermittent connections.

2. Chip latch-up effect: CMOS circuits can enter a high-power state due to overvoltage, even leading to damage.

3. Data loss: Flash memory can suffer bit flips from electrostatic shocks.

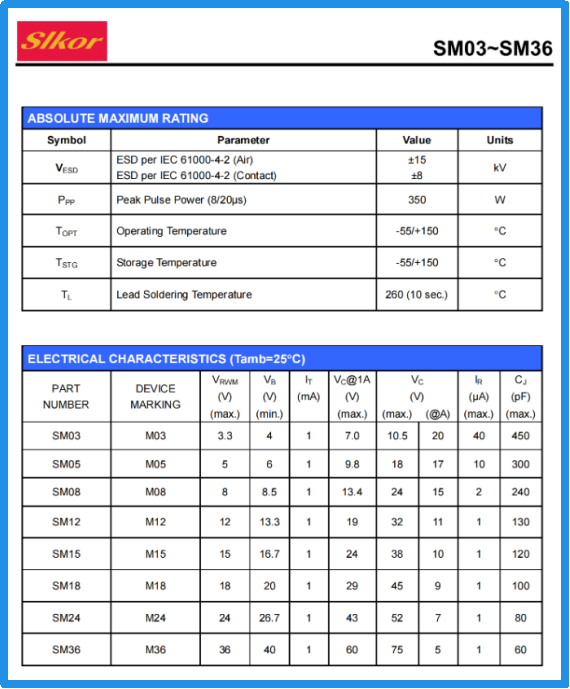

Parameters of Slkor Electrostatic Discharge Diode SM03

The SM03, designed as an electrostatic protection device for low-power Bluetooth, features characteristics that perfectly match the needs of Bluetooth modules:

1. Precise voltage clamping ability:

VRWM=3.3V: It maintains a high impedance state at the Bluetooth module's standard operating voltage to ensure zero signal loss.

VBR min=4V: It initiates avalanche breakdown when the voltage exceeds 4V, rapidly releasing excess voltage.

VC=10.5V: It limits transient voltages to a safe threshold, preventing overvoltage damage to the Bluetooth chip.

This triple-layer protection mechanism acts like an "intelligent voltage regulator" for Bluetooth antenna interfaces, reducing voltage peaks by over 70% during ESD shocks.

2. Ultra-low parasitic effect design:

CJ=450pF: The very low junction capacitance ensures that the edge rate of the 2.4 GHz RF signal is unaffected.

SOT-23 small package: The SM03 can be densely deployed on Bluetooth modules (10mm²), including on antennas, power, and data interfaces.

Test data shows that at Bluetooth 5.0’s 2 Mbps transmission rate, signal attenuation caused by the SM03 is less than 1dB, which fully meets the needs of audio transmission, sensor data feedback, and similar scenarios.

3. Extreme environmental adaptability:

IR=40µA: The microampere reverse leakage current ensures long-term stability.

Operating temperature range: -55°C to 150°C, making it suitable for extreme environments such as automotive and industrial applications.

In tests by a smart wristband manufacturer, Bluetooth modules with SM03 passed the IEC 61000-4-2 level 4 contact discharge test, with ESD failure rates reduced by 90% compared to unprotected systems.

The SM03 can be deployed in various areas of Bluetooth devices:

1. Antenna interfaces: Protecting the Bluetooth RF front-end from electromagnetic interference.

2. Power management units: Preventing voltage spikes during battery charging and discharging from damaging the module.

3. Debugging interfaces: Ensuring the integrity of signals at SWD, JTAG, and other programming interfaces.

A case study by a medical device manufacturer showed that after adopting the SM03 in 2000 Bluetooth thermometers, the repair rate due to electrostatic damage dropped from 3.2% to 0.15%, significantly improving product reliability.

In the interconnected world built by Bluetooth devices, electrostatic protection devices like the SM03 act as the "myelin sheath" of the nervous system, safeguarding wireless signals with nanosecond-level response times. As smart hardware transitions towards "miniaturization and low power," this meticulous attention to detail will ultimately serve as a powerful force driving industrial upgrades.

Slkor has research and development offices in Busan, South Korea, Beijing, China, and Suzhou, China. Most of the wafer manufacturing and packaging and testing are carried out within China. The company employs and collaborates with individuals and organizations worldwide, with a laboratory for product performance and reliability testing and a central warehouse located at its headquarters in Shenzhen. Slkor has filed for over a hundred invention patents, offers more than 2,000 product models, and serves over ten thousand customers globally. Its products are exported to countries and regions including Europe, the Americas, Southeast Asia, and the Middle East, making it one of the rapidly growing semiconductor companies in recent years. With well-established management systems and streamlined workflows, Slkor has rapidly enhanced the brand awareness and reputation of its "SLKOR" brand through its outstanding quality and standardized services. Its product range includes three major series: diodes, transistors, and power devices, with recent introductions of new products such as Hall elements and analog devices, expanding its presence in sensors, Risc-v microcontrollers, and other product categories.

Site Map | 萨科微 | 金航标 | Slkor | Kinghelm

RU | FR | DE | IT | ES | PT | JA | KO | AR | TR | TH | MS | VI | MG | FA | ZH-TW | HR | BG | SD| GD | SN | SM | PS | LB | KY | KU | HAW | CO | AM | UZ | TG | SU | ST | ML | KK | NY | ZU | YO | TE | TA | SO| PA| NE | MN | MI | LA | LO | KM | KN

| JW | IG | HMN | HA | EO | CEB | BS | BN | UR | HT | KA | EU | AZ | HY | YI |MK | IS | BE | CY | GA | SW | SV | AF | FA | TR | TH | MT | HU | GL | ET | NL | DA | CS | FI | EL | HI | NO | PL | RO | CA | TL | IW | LV | ID | LT | SR | SQ | SL | UK

Copyright ©2015-2025 Shenzhen Slkor Micro Semicon Co., Ltd