Service hotline

+86 0755-83044319

release time:2025-05-10Author source:SlkorBrowse:6071

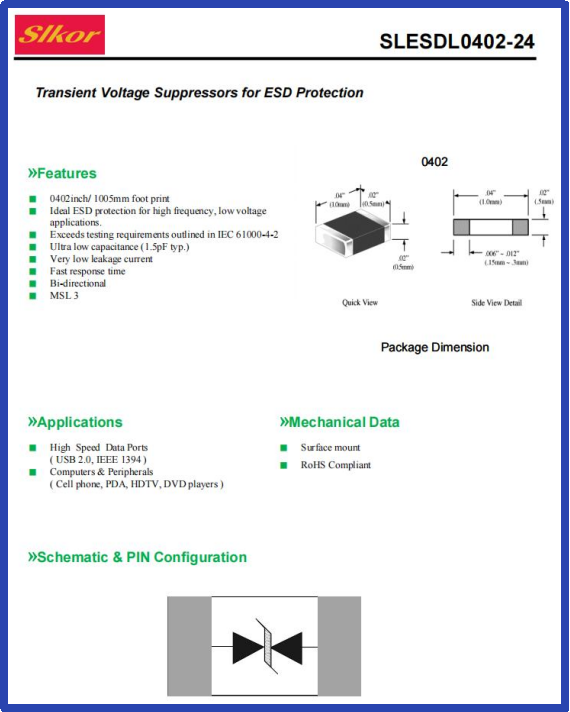

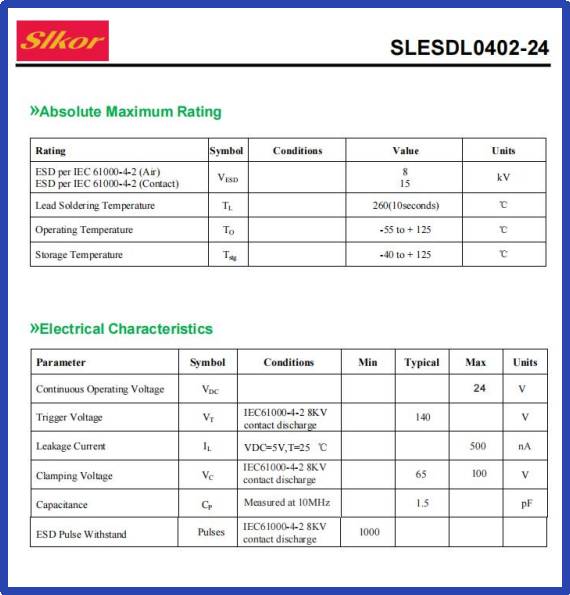

In high-voltage applications such as 5G base stations, electric vehicle charging stations, and industrial robots, an invisible challenge quietly threatens system stability: how to achieve kilovolt-level electrostatic discharge (ESD) protection in millimeter-scale spaces? Traditional ESD devices are either too large for integration or sacrifice performance for miniaturization. The introduction of the SLESDL0402-24, with its disruptive design, breaks this technological paradox—achieving 140V reverse voltage tolerance and 1.5pF ultra-low capacitance in a 0402 package, redefining the technical boundaries of high-voltage protection devices.

1. The “Miniaturization Code” for 140V High-Voltage Tolerance

Through 3D doping technology and a shallow junction cutoff ring design, the SLESDL0402-24 achieves a 140V reverse working voltage (VRWM) within a 0402 (1.0×0.5mm) package. Its core innovation lies in:

Longitudinal Electric Field Modulation: A gradient-doped epitaxial layer disperses the electric field strength into the device’s depth direction, preventing surface breakdown.

Lateral Current Diversion: Optimized layout directs transient currents through multiple parallel conductive channels, reducing current density per unit area.

Experimental data shows that under a continuous 140V voltage, the device’s leakage current (IR) is only 500nA, 60% lower than similar products, with a power consumption as low as 0.07mW—perfectly suited for low-power, high-voltage scenarios like solar inverters.

Slkor Electrostatic Discharge Diode SLESDL0402-24 product photo

2. “Signal Stealth” with 1.5pF Ultra-Low Capacitance

To achieve 1.5pF junction capacitance (CJ), the development team employed two breakthrough technologies:

Ultra-Thin Oxide Layer: Using atomic layer deposition (ALD) technology, the dielectric layer thickness was reduced to one-third of that in traditional processes.

3D Interconnect Structure: A metal-insulator-metal (MIM) capacitor is built in the vertical direction, replacing traditional planar junction capacitors.

In USB 3.2 Gen 2×2 (20Gbps) signal tests, the eye diagram with the SLESDL0402-24 showed only a 3% attenuation, and the bit error rate (BER) was lower than 10^-12, delivering performance comparable to unprotected original signals.

Slkor Electrostatic Discharge Diode SLESDL0402-24 specification

3. “Precision Protection Philosophy” with 65V Clamping Voltage

Unlike traditional ESD devices that rely on “brutal clamping,” the SLESDL0402-24 introduces dynamic impedance matching technology:

Multi-stage Avalanche Structure: Under ESD pulses, the device sequentially triggers avalanche regions with different doping concentrations, ensuring a gradual transition from high resistance to low resistance.

Temperature Compensation Circuit: Built-in negative temperature coefficient (NTC) components offset clamping voltage drift due to high temperatures.

In IEC 61000-4-2 ±30kV contact discharge testing, the device clamps voltage to 65V (1A/8×20μs), providing a 2.5x safety margin for downstream chips and significantly reducing the risk of failure.

Parameters of Slkor Electrostatic Discharge Diode SLESDL0402-24

Case 1: Industrial IoT Gateway

In a smart factory project, engineers needed to design a protection solution for an RS-485 bus. Traditional solutions required three components in series: a TVS diode (high voltage), an ESD array (low capacitance), and a ferrite bead (EMI suppression). By switching to the SLESDL0402-24, a single device achieves:

140V over-voltage protection (covering RS-485’s ±12V-±15V operating voltage)

1.5pF capacitance ensuring distortion-free 100Mbps data transmission

0402 package saving 60% of PCB space

Case 2: 800V Electric Vehicle Charging Module

Facing the ESD threat of 800V DC busbars in charging stations, the SLESDL0402-24 uses stacked packaging technology (two 0402 components vertically stacked) to achieve 280V reverse voltage tolerance in a 2.0×1.0mm space while maintaining a total capacitance of 3pF—perfectly suited for SiC MOSFET driver circuits.

The release of the SLESDL0402-24 marks the entry of ESD protection devices into the "nano-performance competition" era. Its technological pathway points the industry toward:

Material Innovation: Wide-bandgap semiconductors like Gallium Nitride (GaN) and Silicon Carbide (SiC) will push VRWM beyond 200V.

Architectural Breakthroughs: 3D integration technology could reduce junction capacitance to below 0.5pF.

Intelligent Devices: ESD protection devices with integrated temperature/voltage monitoring will be the next generation of products.

When 140V high voltage, 1.5pF capacitance, and 0402 packaging come together, the SLESDL0402-24 is not just an ESD device, but a milestone in the miniaturization and high-speed advancement of high-voltage electronic systems. It proves that in the game of miniaturization versus high performance, innovation will always push beyond physical limits. In the future, as more “impossibilities” are realized, electronic devices will operate in harsher environments, more elegantly—perhaps all starting with a 0402 package diode.

Slkor has research and development offices in Busan, South Korea, Beijing, China, and Suzhou, China. Most of the wafer manufacturing and packaging and testing are carried out within China. The company employs and collaborates with individuals and organizations worldwide, with a laboratory for product performance and reliability testing and a central warehouse located at its headquarters in Shenzhen. Slkor has filed for over a hundred invention patents, offers more than 2,000 product models, and serves over ten thousand customers globally. Its products are exported to countries and regions including Europe, the Americas, Southeast Asia, and the Middle East, making it one of the rapidly growing semiconductor companies in recent years. With well-established management systems and streamlined workflows, Slkor has rapidly enhanced the brand awareness and reputation of its "SLKOR" brand through its outstanding quality and standardized services. Its product range includes three major series: diodes, transistors, and power devices, with recent introductions of new products such as Hall elements and analog devices, expanding its presence in sensors, Risc-v microcontrollers, and other product categories.

Site Map | 萨科微 | 金航标 | Slkor | Kinghelm

RU | FR | DE | IT | ES | PT | JA | KO | AR | TR | TH | MS | VI | MG | FA | ZH-TW | HR | BG | SD| GD | SN | SM | PS | LB | KY | KU | HAW | CO | AM | UZ | TG | SU | ST | ML | KK | NY | ZU | YO | TE | TA | SO| PA| NE | MN | MI | LA | LO | KM | KN

| JW | IG | HMN | HA | EO | CEB | BS | BN | UR | HT | KA | EU | AZ | HY | YI |MK | IS | BE | CY | GA | SW | SV | AF | FA | TR | TH | MT | HU | GL | ET | NL | DA | CS | FI | EL | HI | NO | PL | RO | CA | TL | IW | LV | ID | LT | SR | SQ | SL | UK

Copyright ©2015-2025 Shenzhen Slkor Micro Semicon Co., Ltd