Service hotline

+86 0755-83044319

release time:2025-07-15Author source:SlkorBrowse:951

Manufacturing is the bedrock stabilizing China's economy, and private entrepreneurs make tremendous contributions to social development and innovation. Mr. Chen Jianhua of Xingdong is one such individual. He not only witnessed and participated in the development of the Shenzhen Special Economic Zone but also nurtured a large number of professional technical talents for the mold industry. It is these laborers from all corners of the country who, with their hard work and sweat, transformed Shenzhen from a small fishing village into today's international metropolis.

Chen Jianhua, General Manager of Shenzhen Xingdong Plastic Mold Products Co., Ltd.

Approaching Shenzhen Xingdong Plastic Mold Products Co., Ltd., the roar of machinery in the workshop and the busy figures of workers immediately draw attention. When the Slkor Micro Semicon editorial team arrived at Chen Jianhua's second-floor office at 10 AM, he was enjoying quality time with his wife and their little dog, "Xingxing." Chen Jianhua smiled affectionately as he introduced, "Xingxing is already 14 years old, an old dog now. His hearing and eyesight have deteriorated, but he comes to work with me every day without pay, wouldn't leave even when shooed away."

Mr. Chen Jianhua, along with figures like Kinghelm and Slkor's Song Shiqiang, are entrepreneurs who came to Shenzhen from the "Sichuan-Chongqing region." He is an entrepreneur who grew from a frontline technician. Since entering the industry in 1987, he is now a master craftsman with 38 years of experience in the mold industry. He said he started as an apprentice in a factory after graduating high school, spending 10 months on mold polishing alone. At the time, he complained to his master, "You have me doing this every day," to which the master replied, "This is fundamental; you must settle down and build a solid foundation." He persisted, and it was this perseverance that allowed him, after being laid off, to start his entrepreneurial journey with just three second-hand injection molding machines.

Chen Jianhua practicing Tai Chi in his daily life

In 1997, the wave of state-owned enterprise reforms surged. Chen Jianhua's company, Xianke Precision Mold, was merged and restructured. After being laid off, he decided to co-found "Qingdong Electronics" with two partners. The trio pooled their money to buy three machines and began taking orders to make molds. However, as the company grew, differences in management philosophy emerged among the partners. Consequently, in 2003, Chen Jianhua chose to start his own business. He named it "Xingdong," signifying that the company was like an "Eastern Star, with infinite possibilities for the future," and established Shenzhen Xingdong Plastic Mold Products Co., Ltd.

After 22 years of development, Shenzhen Xingdong Plastic Mold Products Co., Ltd. now boasts over 90 advanced pieces of equipment and has production bases in Shenzhen, Zhongshan, and Anhui. The company mainly produces molds for charging gun heads for charging piles, shared power banks, car air purifiers, laptop shells, litter boxes, and more. "Actually, as long as it's related to molds, we can do it," Chen Jianhua said.

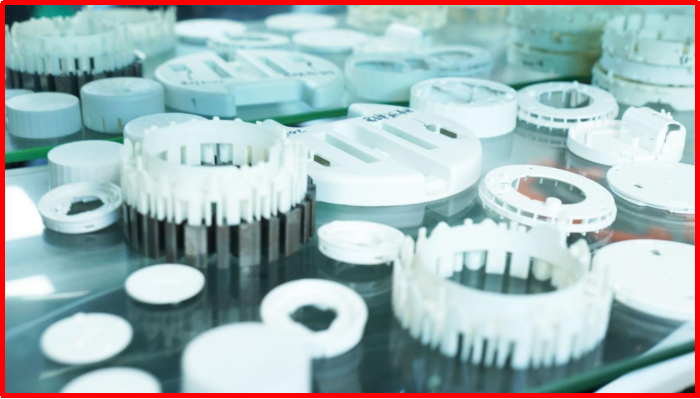

Display of Xingdong Mold finished products

Display of Xingdong small parts molds

In Xingdong's sample room, a dazzling array of mold samples is on display. Chen Jianhua led the reporter into the sample room, explaining: "These are molds we've produced over the years. Take this litter box, for example; its production process is very complex, and it took us about 90 days to make." He then pointed to a row of black products: "These require our Frank injection molding machines in Building 6 to produce; domestic machines can't handle that for now. For laptop shells like this one, we cooperate with brands like Lenovo, Tsinghua Tongfang, Acer, Toshiba Japan, and Great Wall."

Chen Jianhua introduces the mold for laptop shells

Large-size mold product at Xingdong Company – Battery tray for electric buses

"This is the mold for parts used inside Midea refrigerator compressors. One refrigerator compressor requires 10 plastic parts. I recall we made molds worth over 1.1 million RMB for them in 2003; now, the Zhongshan plant should have sales exceeding 70 million RMB," Chen Jianhua said. In 2003, Xingdong started collaborating with Midea right after its establishment. In 2005, based on product quality and stable supply capability, Xingdong received the "Qualified Supplier" plaque awarded by Midea. As cooperation deepened, to better meet Midea's demand for nearby supporting facilities, Chen Jianhua opened branch factories in Zhongshan and Anhui.

The "Qualified Supplier" plaque awarded to Xingdong Company by Midea

Entering Xingdong's mold manufacturing workshop, every step of the mold-making process is orderly. Chen Jianhua guided the reporter through the production process: "I rented Buildings 5, 6, and 7 here for mold making, injection molding, and painting/printing workshops. It operates 24/7. For shared power bank molds like these, we have many models – 8-port, 10-port – and we can produce about 1,300 pieces per day." He noted that many molds appear simple but involve complex processes, with numerous parts needing installation inside the product.

Xingdong employees working on shared power bank molds

Xingdong sources many key pieces of equipment from Japan. Chen Jianhua admitted that domestic equivalents still lag in precision and stability, making some products impossible to produce with domestic equipment for now. "For ultra-thin laptop shells, some products have special specifications requiring hot-melt processes." Pointing to a 1600-ton large injection molding machine, he said: "We purchased this machine to produce the radome molds for Ericsson's 5G base stations. Now it's also used for large molds like litter boxes. This machine is extremely heavy, requiring very high foundation standards. We had to excavate some concrete from the factory floor here and pour a 1.1-meter thick concrete pad to support its weight."

*1600-ton injection molding machine*

Xingdong mold production equipment

From raw material procurement to finished product inspection, Xingdong has a comprehensive internal quality assurance system, with dedicated personnel responsible for each step. Chen Jianhua mentioned that the company is very cautious in selecting raw material suppliers. Due to inconsistent quality control among some domestic suppliers, they primarily use imported materials. He once suffered losses due to material issues from a domestic supplier, leading to quality problems in the foreign market and ultimately having to compensate the client. Since then, he has become even more resolute in maintaining strict quality requirements.

Testing machine at Xingdong Company

At Xingdong, technology is inherited. Now 57 years old, Chen Jianhua is gradually stepping back from frontline management, entrusting daily operations to his apprentices. "Many key personnel, supervisors, and managers here are apprentices I trained; all their skills were taught by me," he said. However, looking at the frontline workers in the workshop, whose average age exceeds 50, he also expressed concern: "Only technical positions in Building 7 attract young people. Nowadays, young people born in the 90s and 00s, even if they learn some skills, are reluctant to do this work." He hopes more young people will enter factories in the future, settle down to learn skills, and take up the baton from the older generation.

Recalling his entrepreneurial days, Chen Jianhua felt time was very fulfilling. "Back then, I was constantly thinking about how to control quality, deliver goods on time, collect payments to pay salaries, and maintain the company's operations." After stepping back, he devotes more time to life, enjoying reading and practicing Tai Chi when he can. He occasionally monitors employees' work status in WeChat groups and promptly provides corrections and guidance if technical issues or operational errors are spotted.

From age 19 to 57, Chen Jianhua has dedicated 38 years to the mold industry. He has not only built a modern mold manufacturing enterprise but also cultivated generations of highly skilled industry talents. In him, we see a microcosm of China's manufacturing development – that persistent pursuit of technology and extreme dedication to quality vividly embody the "Craftsman Spirit."

Site Map | 萨科微 | 金航标 | Slkor | Kinghelm

RU | FR | DE | IT | ES | PT | JA | KO | AR | TR | TH | MS | VI | MG | FA | ZH-TW | HR | BG | SD| GD | SN | SM | PS | LB | KY | KU | HAW | CO | AM | UZ | TG | SU | ST | ML | KK | NY | ZU | YO | TE | TA | SO| PA| NE | MN | MI | LA | LO | KM | KN

| JW | IG | HMN | HA | EO | CEB | BS | BN | UR | HT | KA | EU | AZ | HY | YI |MK | IS | BE | CY | GA | SW | SV | AF | FA | TR | TH | MT | HU | GL | ET | NL | DA | CS | FI | EL | HI | NO | PL | RO | CA | TL | IW | LV | ID | LT | SR | SQ | SL | UK

Copyright ©2015-2025 Shenzhen Slkor Micro Semicon Co., Ltd