Service hotline

+86 0755-83044319

release time:2025-06-23Author source:SlkorBrowse:1280

In the era of Industry 4.0, industrial charging equipment has become a core infrastructure in sectors such as automated production lines, smart warehousing, and electric transportation. As charging power continues to rise and communication speeds accelerate, industrial charging systems are facing increasing electrostatic discharge (ESD) threats. The SLESD8D36V electrostatic protection diode, introduced by Slkor, offers an efficient and reliable ESD protection solution for industrial charging systems, thanks to its 36V high reverse breakdown voltage, fast response time, and compact packaging.

Slkor Electrostatic Discharge Diode SLESD8D36V product photo

Industrial charging devices typically operate in complex electromagnetic environments where the risk of ESD is ever-present. For instance, in automated factories, frequent contact between robotic arms and charging stations can generate thousands of volts of static electricity. In outdoor charging stations, environmental factors such as dust, rain, and snow can exacerbate static buildup on equipment surfaces. Furthermore, in high-precision charging control circuits, even small ESD pulses can cause sensor malfunctions, communication disruptions, or even damage to power devices. Industry data shows that approximately 35% of failures in industrial charging equipment are ESD-related, with communication interfaces and power modules being the most vulnerable.

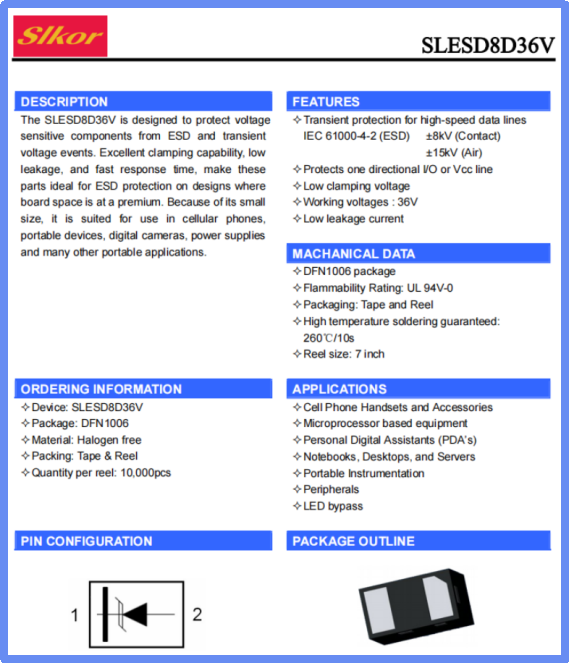

Slkor Electrostatic Discharge Diode SLESD8D36V specification

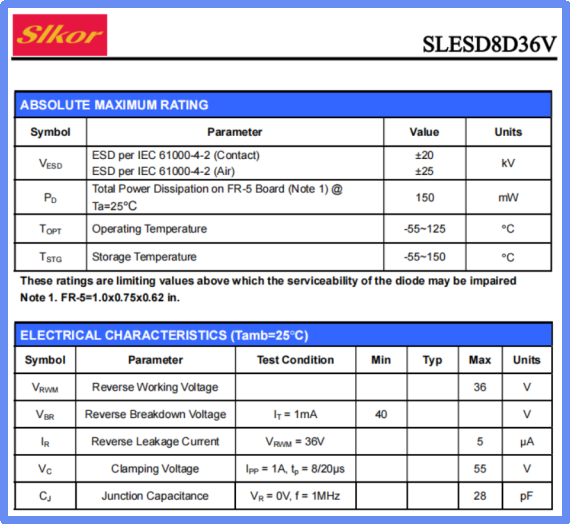

The SLESD8D36V’s electrical parameters are designed to meet the core needs of industrial charging systems. Its 36V reverse working voltage (VRWM) covers the voltage range for mainstream industrial charging protocols (such as CCS, GB/T, etc.), ensuring it remains in a high-impedance state during normal charging to avoid interference with communication signals like CAN bus, RS-485, or Ethernet. When subjected to an ESD shock, the device responds in picoseconds, clamping the voltage (VC) to a stable 55V, effectively protecting downstream charging control chips (such as ST L9963, Infineon TLE94112) from transient overvoltage impacts.

With a junction capacitance (CJ) of 28pF, the SLESD8D36V strikes a unique balance in industrial charging applications. Compared to consumer-grade ESD devices, this capacitance value maintains signal integrity (such as 10Mbps CAN FD communication) while offering robust protection, preventing signal reflection or timing errors caused by excessive capacitance. The low 5μA leakage current (IR) reduces static power consumption, which is particularly beneficial in energy-sensitive scenarios such as solar charging stations and outdoor energy storage systems.

Parameters of Slkor Electrostatic Discharge Diode SLESD8D36V

In industrial charging stations, the SLESD8D36V can be deployed between the charging gun and the control board to protect the charging connection confirmation (CC) signal line and communication buses from ESD damage during plug and unplug operations. Its DFN1006 package (1.0mm x 0.6mm) is only one-third the size of traditional SOT-23 packages, making it easy to integrate into compact charging control boards and meet the miniaturization trend in industrial equipment. In electric forklift or AGV battery management systems (BMS), the device can protect SPI/I2C communication interfaces between the BMS and charging modules, preventing ESD-induced errors in battery state-of-charge (SOC) estimation or charging strategy failure.

In outdoor industrial charging environments, the SLESD8D36V’s wide operating temperature range of -40°C to +125°C allows it to function in extreme conditions. Its minimum breakdown voltage (VBR min) of 40V is designed to withstand transient overvoltage events, such as lightning surges. For example, in the charging systems of wind turbines, this device can protect yaw motor charging interfaces from both dust-induced ESD and lightning strikes.

The SLESD8D36V employs Slkor’s self-developed “high-bandgap semiconductor composite materials,” using ion implantation and gradient doping technologies to precisely control the breakdown voltage and capacitance. Its three-dimensional electrode structure reduces surface electric field strength, ensuring that the device’s clamping voltage fluctuation during an 8kV contact discharge test is less than 5%.

For example, after deploying the SLESD8D36V in its AGV charging system, a smart warehousing company saw the ESD failure rate of charging interfaces drop from 8 times per month to zero, eliminating communication interruptions and reducing annual maintenance costs by over 3,000 yuan per unit. In the electric forklift sector, a logistics company experienced a 75% decrease in BMS system false reporting rates, a 12% increase in battery life, and a 10% improvement in overall operational efficiency.

As industrial charging systems evolve toward higher power and greater reliability, the SLESD8D36V electrostatic protection diode has become a key choice for engineers optimizing charging circuits, thanks to its precise parameter design, miniaturized packaging, and exceptional protective performance. With the deeper integration of industrial IoT and energy management technologies, these high-performance ESD devices will play an even greater role in industrial charging equipment, building a robust [敏感词] for the energy infrastructure of smart manufacturing.

Slkor has research and development offices in Busan, South Korea, Beijing, China, and Suzhou, China. Most of the wafer manufacturing and packaging and testing are carried out within China. The company employs and collaborates with individuals and organizations worldwide, with a laboratory for product performance and reliability testing and a central warehouse located at its headquarters in Shenzhen. Slkor has filed for over a hundred invention patents, offers more than 2,000 product models, and serves over ten thousand customers globally. Its products are exported to countries and regions including Europe, the Americas, Southeast Asia, and the Middle East, making it one of the rapidly growing semiconductor companies in recent years. With well-established management systems and streamlined workflows, Slkor has rapidly enhanced the brand awareness and reputation of its "SLKOR" brand through its outstanding quality and standardized services. Its product range includes three major series: diodes, transistors, and power devices, with recent introductions of new products such as Hall elements and analog devices, expanding its presence in sensors, Risc-v microcontrollers, and other product categories.

Site Map | 萨科微 | 金航标 | Slkor | Kinghelm

RU | FR | DE | IT | ES | PT | JA | KO | AR | TR | TH | MS | VI | MG | FA | ZH-TW | HR | BG | SD| GD | SN | SM | PS | LB | KY | KU | HAW | CO | AM | UZ | TG | SU | ST | ML | KK | NY | ZU | YO | TE | TA | SO| PA| NE | MN | MI | LA | LO | KM | KN

| JW | IG | HMN | HA | EO | CEB | BS | BN | UR | HT | KA | EU | AZ | HY | YI |MK | IS | BE | CY | GA | SW | SV | AF | FA | TR | TH | MT | HU | GL | ET | NL | DA | CS | FI | EL | HI | NO | PL | RO | CA | TL | IW | LV | ID | LT | SR | SQ | SL | UK

Copyright ©2015-2025 Shenzhen Slkor Micro Semicon Co., Ltd