Service hotline

+86 0755-83044319

release time:2025-05-07Author source:SlkorBrowse:4375

In the 5G era of the Internet of Things, Bluetooth technology has become the "nervous system" of smart terminal devices. From TWS earphones to smartwatches, from in-car Bluetooth modules to IoT sensors, the demand for high-frequency, high-speed, low-power wireless connections is driving Bluetooth chips toward more advanced process nodes. However, the performance leap brought about by nanometer-level processes has made electrostatic discharge (ESD) a "Sword of Damocles" hanging over designers. In this context, the GBLC03CI ESD protection diode, with its ultra-low junction capacitance, miniature packaging, and precise protective characteristics, is becoming the core solution for ESD protection in Bluetooth devices.

Slkor Electrostatic Discharge Diode GBLC03CI product photo

The working environment of Bluetooth devices determines the complexity of their ESD protection:

Human contact risk: During daily use, friction between the user's fingers and the device's shell or buttons can generate electrostatic charges of thousands of volts.

Exposed interfaces: Open interfaces like USB-C charging ports and headphone jacks are the main pathways for ESD intrusion.

Wireless coupling: The 2.4GHz frequency band overlaps with ESD transient pulses, which may cause signal interference.

Without effective protection, ESD events may lead to:

RF front-end damage: Burning out power amplifiers (PA) or low-noise amplifiers (LNA).

Digital baseband failure: Causing Bluetooth protocol stack crashes or connection interruptions.

Battery management anomalies: Triggering over-voltage or over-current protection circuits.

To address the specific needs of Bluetooth devices, ESD protection components must meet the following requirements:

Ultra-low junction capacitance (CJ): To maintain the integrity of 2.4GHz signals.

Miniature packaging: To fit compact PCB spaces in wearable devices.

Fast response time: To achieve effective clamping under nanosecond-level ESD pulses.

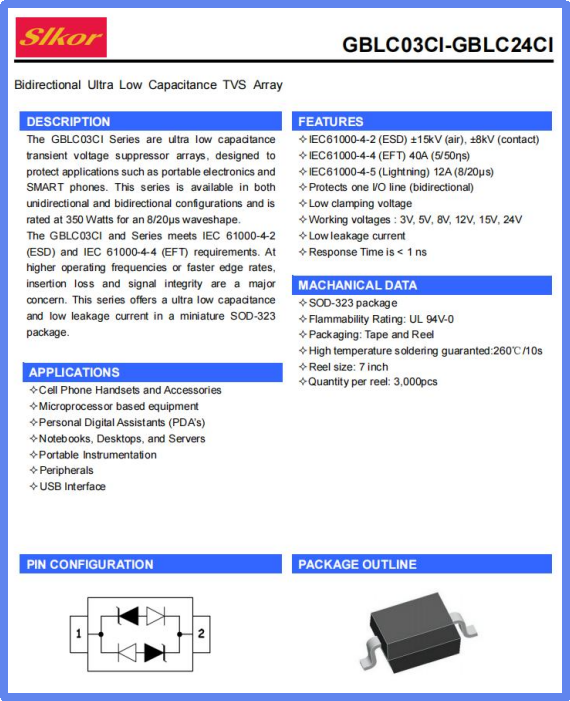

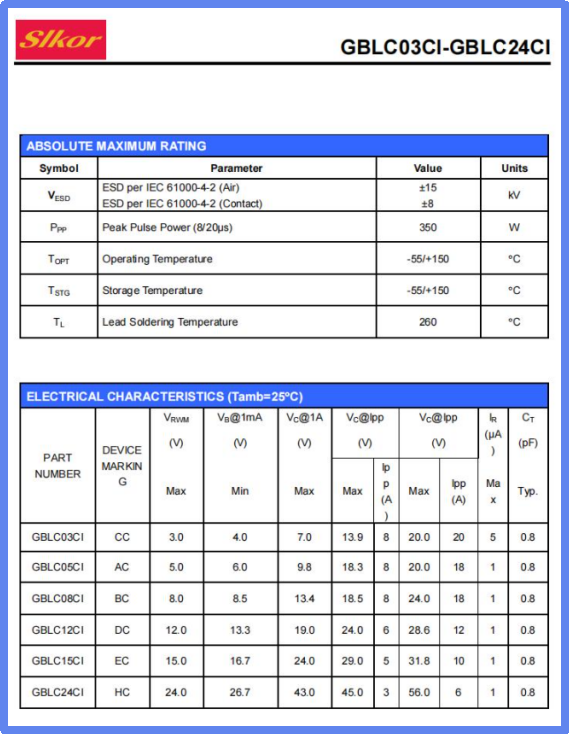

As an ESD solution optimized for high-frequency applications, the GBLC03CI's parameters align perfectly with the needs of Bluetooth devices:

| Parameter | Value | Technical Significance |

| VRWM | 3V | Matches the low voltage supply (1.2V-3.3V) of Bluetooth chips |

| VBR min | 4V | Precise trigger threshold to prevent false triggering |

| IR | 5μA | Ultra-low leakage current to extend battery life |

| VC | 7V | Strictly limits ESD overshoot voltage to protect RF components |

| CJ | 0.8pF | Nearly "invisible" capacitive load, ensuring signal quality |

| package | SOD-323 | Compact size of only 2.5×1.3mm, suitable for high-density layouts |

Slkor Electrostatic Discharge Diode GBLC03CI specification

Parameters of Slkor Electrostatic Discharge Diode GBLC03CI

1. Antenna Interface Protection

The antenna feed of Bluetooth modules is a high-risk path for ESD intrusion. GBLC03CI can be deployed to:

Protect power amplifiers (PA) and low-noise amplifiers (LNA) between the RF switch and the antenna.

Prevent impedance mismatch caused by ESD in the antenna matching network, maintaining radiation efficiency.

Test data: At the 2.4GHz frequency band, GBLC03CI increased the antenna port ESD protection level from ±2kV to ±8kV while maintaining -50dB return loss (S11).

2. USB/Type-C Interface Protection

Bluetooth devices such as speakers and in-car modules need to withstand electrostatic charges generated by frequent plugging and unplugging of USB interfaces. GBLC03CI can:

Be connected in parallel with D+/Ddata lines to absorb ±15kV contact discharge.

Work with common-mode inductors to form differential-mode/common-mode mixed protection.

Case study: After using GBLC03CI, a brand of TWS earphones saw the return rate due to static electricity from USB interfaces drop from 2.8% to 0.15%.

3. Button and Touch Panel Protection

Physical buttons and capacitive touch modules are major discharge paths for human static electricity. GBLC03CI can:

Protect button matrix scanning lines to prevent damage to MCU GPIO pins.

Maintain signal-to-noise ratio (SNR) in touch chips (e.g., Atmel maXTouch®).

Comparison test: Compared to a similar device with a 1.5pF junction capacitance, GBLC03CI increased the ESD tolerance of touch panels by 30%, while maintaining 98% touch recognition rate.

4. Future Trends: High-Frequency and Integration Driving Technological Evolution

As Bluetooth technology evolves towards LE Audio, AoA/AoD positioning, and other advancements, ESD protection needs will show the following trends:

Ultra-low capacitance competition: Junction capacitance will break through 0.5pF, adapting to 60GHz millimeter-wave applications.

Multi-band coverage: Single chips will support 2.4GHz/5GHz/6GHz protection.

Smart diagnostics: Integrated ESD event counters to visualize protection status.

The GBLC03CI, as a benchmark product at the current technology node, offers an optimal balance between performance and cost for Bluetooth devices with its 3V operating voltage, 0.8pF ultra-low capacitance, and SOD-323 packaging. Through precise ESD protection design, manufacturers can significantly enhance product reliability, reduce after-sales costs, and gain a competitive edge in the market.

As Bluetooth devices evolve to become smaller, faster, and smarter, ESD protection has transitioned from being an "optional accessory" to a "necessary component." With its 0.8pF performance and SOD-323 miniature form, GBLC03CI has redefined the protection standard for high-frequency applications. In the future, with breakthroughs in material science and packaging processes, ESD diodes will deeply integrate with Bluetooth chips to build a new wireless connection ecosystem resistant to electrostatic interference.

Site Map | 萨科微 | 金航标 | Slkor | Kinghelm

RU | FR | DE | IT | ES | PT | JA | KO | AR | TR | TH | MS | VI | MG | FA | ZH-TW | HR | BG | SD| GD | SN | SM | PS | LB | KY | KU | HAW | CO | AM | UZ | TG | SU | ST | ML | KK | NY | ZU | YO | TE | TA | SO| PA| NE | MN | MI | LA | LO | KM | KN

| JW | IG | HMN | HA | EO | CEB | BS | BN | UR | HT | KA | EU | AZ | HY | YI |MK | IS | BE | CY | GA | SW | SV | AF | FA | TR | TH | MT | HU | GL | ET | NL | DA | CS | FI | EL | HI | NO | PL | RO | CA | TL | IW | LV | ID | LT | SR | SQ | SL | UK

Copyright ©2015-2025 Shenzhen Slkor Micro Semicon Co., Ltd