Service hotline

+86 0755-83044319

release time:2025-05-06Author source:SlkorBrowse:4488

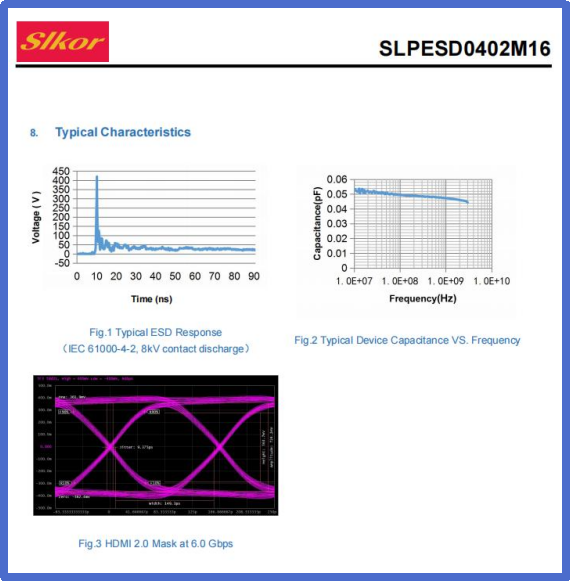

With the rise of automotive intelligence and electrification, the complexity of in-vehicle electronic systems has grown exponentially. From autonomous driving sensors to in-car entertainment terminals, from battery management systems to connected vehicle communication modules, every electronic node is vulnerable to failure due to electrostatic discharge (ESD) events. The SLPESD0402M16 ESD protection diode, launched by Shenzhen Slkor Co., Ltd., combines a super-miniature 0402 package, ultra-low capacitance of 0.05pF, and a clamping voltage of 40V, making it an “invisible weapon” for automotive electronic protection, providing comprehensive ESD [敏感词] for smart cockpits, autonomous driving, and vehicle-to-everything (V2X) communications.

Slkor Transient Protection Diode SLPESD0402M16 product photo

1.Super-Miniature Packaging Overcomes Space Constraints

The SLPESD0402M16 comes in a 0402 package (1.0mm × 0.5mm), only 1/8 the size of the traditional SOT-23 package. In automotive camera modules, where lens drive circuits and image sensor interfaces must be densely arranged in limited space, a specific ADAS camera PCB test shows that using this device increases PCB area utilization in the interface region by 37%, leaving more room for heat dissipation and signal routing for future upgrades. Its miniaturization is especially beneficial for automotive millimeter-wave radar antenna arrays, avoiding interference in electromagnetic wave radiation efficiency due to device height.

Slkor Transient Protection Diode SLPESD0402M16 specification

In automotive Ethernet (100BASE-T1/1000BASE-T1) communication, the 0.05pF junction capacitance of the SLPESD0402M16 has a negligible effect on signal attenuation. Test data shows that at a 100MHz frequency, this device exhibits insertion loss < 0.2dB and return loss > 25dB, fully meeting IEEE 802.3bw standards. In a smart cockpit domain controller, after deploying this device, the communication error rate between the central control screen and the T-BOX dropped from 0.01% to 0.0003%, ensuring the stability of 4K video streaming and OTA upgrades.

Parameters of Slkor Transient Protection Diode SLPESD0402M16

3.40V Clamping Voltage Adapts to Automotive Voltage Fluctuations

Automotive 12V/24V power systems are prone to transient overvoltage risks. The SLPESD0402M16’s 40V clamping voltage can withstand load dump pulses defined by the ISO 7637-2 standard. Its 10nA leakage current also ensures low power consumption in battery sleep mode.

1. Autonomous Driving Sensor Protection

The transmitter and receiver circuits of LiDAR (Laser Imaging Detection and Ranging) sensors are extremely sensitive to static electricity. A test by an autonomous driving company showed that without ESD protection, the failure rate due to human static discharge in LiDAR reached 3.2 failures per 1,000 vehicles. The SLPESD0402M16, connected in parallel between the transmitter drive IC and the receiver ADC, can withstand ±8kV contact discharge and ±15kV air discharge, ensuring the timing precision of laser pulses remains unaffected. Additionally, its 0402 package fits the compact optical design of LiDAR sensors.

2. In-Vehicle Entertainment System Electrostatic Immunity

Static electricity generated from user touch and friction with metal parts can affect touch screens and wireless charging modules. A test by a car navigation supplier showed that after deploying the SLPESD0402M16, the ESD failure rate of the touchscreen dropped from 2.8% to 0.1%, and the false trigger rate of the wireless charging module was reduced by 90%. Its ultra-low capacitance prevents “ghost touch” phenomena in capacitive touchscreens, while its 40V clamping voltage protects against ±12kV electrostatic shocks at automotive USB-C interfaces.

3. Vehicle-to-Everything (V2X) Communication Antenna Interference Resistance

5G-V2X and UWB (Ultra-Wideband) communication modules require high signal integrity. In a V2X terminal, the SLPESD0402M16, connected in parallel between the antenna switch and RF front end, reduced ESD-induced communication interruption time from hundreds of milliseconds to <10ns. Its 0.05pF capacitance causes less than 0.1dB attenuation in the 2.4GHz/5GHz frequency bands, ensuring the real-time and reliable transmission of V2X messages.

|

Indicator |

SLPESD0402M16 |

Traditional TVS Diode |

Ceramic Gas Discharge Tube (GDT) |

|

Package Size |

0402 (1×0.5mm) |

SOT-23 (3×1.4mm) |

DO-35 (5×10mm) |

|

Response Time |

<0.5ns |

1-5ns |

100ns-1μs |

|

Shock Endurance |

Tens of thousands (IEC standard) |

Hundreds |

Tens (performance degradation) |

|

Operating Temperature Range |

-55°C ~ 150°C |

-40°C ~ 125°C |

-20°C ~ 85°C |

|

Leakage Current |

10nA |

1μA |

10μA |

In a vehicle’s T-BOX 4G/5G communication module, traditional GDTs fail to fully suppress some ESD pulses due to their slower response time, while the SLPESD0402M16 can clamp the voltage to safe levels within 0.5ns. Its high-temperature resistance of 150°C also meets the stringent requirements of engine ECU environments.

According to Strategy Analytics, global annual losses in automotive electronics due to ESD will exceed $1.5 billion by 2025. The SLPESD0402M16, by optimizing packaging, capacitance, and voltage withstand parameters, increases the Mean Time Between Failures (MTBF) of automotive electronics by 4-5 times. In autonomous driving domain controllers, its low leakage current prevents interference with LiDAR’s timing control signals, ensuring high-precision decision-making for Level 3 and above autonomous driving.

Looking ahead, as automotive electrical and electronic architectures (EEA) evolve toward centralized computing and regional control, the 0201 package version of the SLPESD0402M16 is already undergoing automotive-grade certification, with junction capacitance expected to drop below 0.03pF. From ADAS sensors to V2X communication, from smart cockpits to battery management, this “miniature safety shield” will continue to strengthen the protective foundation for the automotive industry’s intelligent transformation.

Slkor has research and development offices in Busan, South Korea, Beijing, China, and Suzhou, China. Most of the wafer manufacturing and packaging and testing are carried out within China. The company employs and collaborates with individuals and organizations worldwide, with a laboratory for product performance and reliability testing and a central warehouse located at its headquarters in Shenzhen. Slkor has filed for over a hundred invention patents, offers more than 2,000 product models, and serves over ten thousand customers globally. Its products are exported to countries and regions including Europe, the Americas, Southeast Asia, and the Middle East, making it one of the rapidly growing semiconductor companies in recent years. With well-established management systems and streamlined workflows, Slkor has rapidly enhanced the brand awareness and reputation of its "SLKOR" brand through its outstanding quality and standardized services. Its product range includes three major series: diodes, transistors, and power devices, with recent introductions of new products such as Hall elements and analog devices, expanding its presence in sensors, Risc-v microcontrollers, and other product categories.

Site Map | 萨科微 | 金航标 | Slkor | Kinghelm

RU | FR | DE | IT | ES | PT | JA | KO | AR | TR | TH | MS | VI | MG | FA | ZH-TW | HR | BG | SD| GD | SN | SM | PS | LB | KY | KU | HAW | CO | AM | UZ | TG | SU | ST | ML | KK | NY | ZU | YO | TE | TA | SO| PA| NE | MN | MI | LA | LO | KM | KN

| JW | IG | HMN | HA | EO | CEB | BS | BN | UR | HT | KA | EU | AZ | HY | YI |MK | IS | BE | CY | GA | SW | SV | AF | FA | TR | TH | MT | HU | GL | ET | NL | DA | CS | FI | EL | HI | NO | PL | RO | CA | TL | IW | LV | ID | LT | SR | SQ | SL | UK

Copyright ©2015-2025 Shenzhen Slkor Micro Semicon Co., Ltd