Service hotline

+86 0755-83044319

release time:2025-05-14Author source:SlkorBrowse:1835

Driven by the dual forces of the "dual carbon" strategy and the surge in demand for urban short-distance travel, the electric two-wheeler and three-wheeler market is undergoing a leap from "functional" to "smart" vehicles. In 2023, global sales of electric two-wheelers exceeded 65 million, with over 40% of models equipped with smart features such as intelligent dashboards, keyless ignition, and OTA upgrades. However, as these highly electronic vehicles enhance user experience, they also face the serious challenge of electrostatic discharge (ESD), an invisible threat. In this context, the SLESD9D5.0CT5G electrostatic protection diode in SOD-923 packaging, with its precise parameter design, has become the core component for ensuring the reliability of electric vehicle electronic systems.

Slkor Electrostatic Discharge Diode SLESD9D5.0CT5G product photo

Modern electric vehicles have moved beyond the traditional "transportation tool" to become mobile intelligent terminals:

Smart interaction systems: Features like touch dashboards, voice control, and smartphone app connectivity rely on high-speed data buses.

Energy management systems: The BMS (battery management system) monitors the status of over 100 battery cells in real time.

Power control units: The FOC motor controller processes high-frequency PWM signals for precise drive control.

However, in real-world scenarios, electrostatic risks are omnipresent:

1. User operations: Human body static electricity (up to 30kV) can enter the system through touchscreens and USB charging ports.

2. Environmental interference: Electrostatic buildup from friction in dry environments and charges induced by high-voltage power lines.

3. Manufacturing processes: Static accumulation during assembly lines can cause latent damage to components.

These factors can lead to system crashes, data loss, or even permanent damage to power devices, directly impacting driving safety.

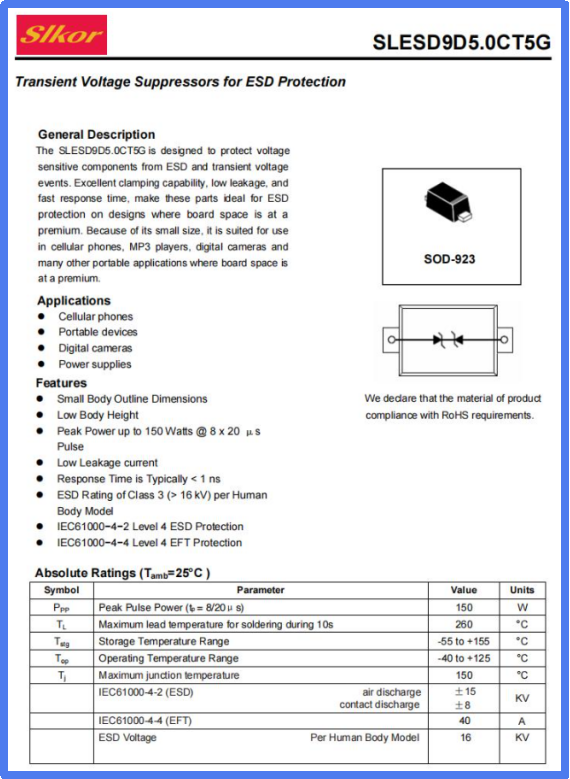

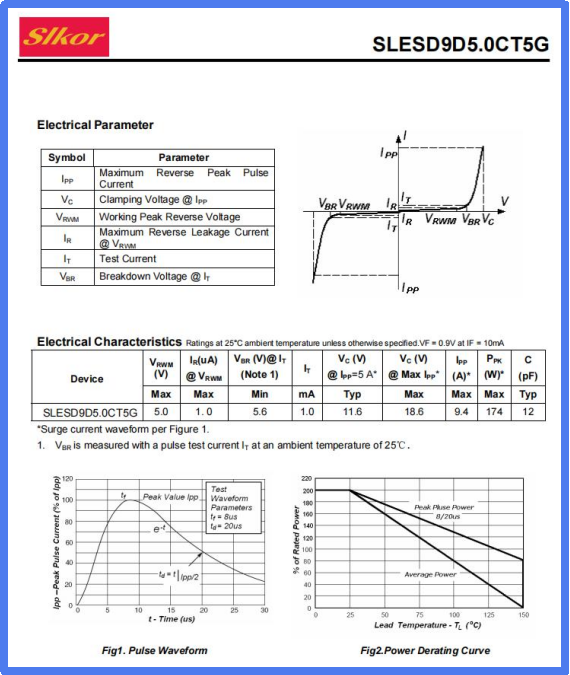

Slkor Electrostatic Discharge Diode SLESD9D5.0CT5G specification

Parameters of Slkor Electrostatic Discharge Diode SLESD9D5.0CT5G

1. Electrical performance tailored to smart electric vehicle needs:

VRWM=5V: Perfectly matches low-voltage communication interfaces such as CAN (5V logic level) and LIN buses.

VBR min=5.6V: Protection is activated when ESD exceeds 5.6V, preventing signal interruptions caused by false triggering.

VC=11.6V: During IEC 61000-4-2 standard 8kV contact discharge testing, the voltage is clamped to 11.6V, below the typical MCU breakdown voltage of 12V, ensuring core processor safety.

2. High-speed signal integrity protection:

CJ=12pF: Compared to traditional TVS diodes (usually >50pF), the low junction capacitance design ensures less than 3ns signal rise-time distortion, ensuring no packet loss in high-speed communications like CAN bus (1Mbps).

3. Space and power consumption optimization:

SOD-923 package (0.6×0.3mm): The size is only 1/3 of that of an SOT-23 package, making it ideal for the limited PCB space in electric vehicle controllers.

IR=1μA: The micro-ampere leakage current results in an annual energy consumption of just 0.004Wh in a 48V battery system, which is negligible.

1. Smart dashboard protection:

The FPC (flexible printed circuit) cable of the touchscreen display is easily susceptible to ESD interference from the human body. By connecting the SLESD9D5.0CT5G in parallel to the I2C bus (SDA/SCL), it suppresses ±15kV air discharge and ensures a touch response delay of less than 50ms.

2. Charging port protection:

Deploying this device in Type-C or national standard charging socket signal lines, its 11.6V clamping voltage can protect against overvoltage surges caused by poor grounding of charging piles, preventing BMS chip damage.

3. Motor controller protection:

For PWM signal lines in three-phase inverters, using a combination of "SLESD9D5.0CT5G + common-mode inductance" absorbs ESD while filtering high-frequency noise, improving FOC control precision.

As electric vehicles evolve towards V2X (vehicle-to-everything) connectivity, the use of in-vehicle Ethernet and 4G/5G modules will introduce higher-frequency ESD threats. The technology evolution path for the SLESD9D5.0CT5G is clear:

Ultra-low capacitance: Next-generation products are planned to reduce CJ to 8pF, making them compatible with 100Mbps in-vehicle Ethernet.

Integration: Development of multi-channel array packaging to simplify PCB designs.

Smart protection: Integration with voltage monitoring chips for real-time ESD event logging and alerts.

In the smart transformation of electric two-wheelers and three-wheelers, the SLESD9D5.0CT5G electrostatic protection diode acts as an "invisible guardian," forming the first line of [敏感词] for the electronic systems. Its precisely designed technical parameters not only resolve the conflicts between space, power consumption, and performance but also drive the evolution of electric vehicles from merely "rideable" to "safe to ride and intelligently usable." As the trillion-dollar micro-mobility market continues to expand, innovation in foundational components like this will be the driving force behind industry upgrades.

Slkor has research and development offices in Busan, South Korea, Beijing, China, and Suzhou, China. Most of the wafer manufacturing and packaging and testing are carried out within China. The company employs and collaborates with individuals and organizations worldwide, with a laboratory for product performance and reliability testing and a central warehouse located at its headquarters in Shenzhen. Slkor has filed for over a hundred invention patents, offers more than 2,000 product models, and serves over ten thousand customers globally. Its products are exported to countries and regions including Europe, the Americas, Southeast Asia, and the Middle East, making it one of the rapidly growing semiconductor companies in recent years. With well-established management systems and streamlined workflows, Slkor has rapidly enhanced the brand awareness and reputation of its "SLKOR" brand through its outstanding quality and standardized services. Its product range includes three major series: diodes, transistors, and power devices, with recent introductions of new products such as Hall elements and analog devices, expanding its presence in sensors, Risc-v microcontrollers, and other product categories.

Site Map | 萨科微 | 金航标 | Slkor | Kinghelm

RU | FR | DE | IT | ES | PT | JA | KO | AR | TR | TH | MS | VI | MG | FA | ZH-TW | HR | BG | SD| GD | SN | SM | PS | LB | KY | KU | HAW | CO | AM | UZ | TG | SU | ST | ML | KK | NY | ZU | YO | TE | TA | SO| PA| NE | MN | MI | LA | LO | KM | KN

| JW | IG | HMN | HA | EO | CEB | BS | BN | UR | HT | KA | EU | AZ | HY | YI |MK | IS | BE | CY | GA | SW | SV | AF | FA | TR | TH | MT | HU | GL | ET | NL | DA | CS | FI | EL | HI | NO | PL | RO | CA | TL | IW | LV | ID | LT | SR | SQ | SL | UK

Copyright ©2015-2025 Shenzhen Slkor Micro Semicon Co., Ltd