Service hotline

+86 0755-83044319

release time:2025-05-24Author source:SlkorBrowse:986

As the wave of smart homes sweeps across the globe, dishwashers, as a benchmark product in the kitchen appliance sector, are undergoing a profound transformation, shifting from a single-function device to an integrated smart system. This technological revolution is not only evident in the breakthrough improvements in cleaning efficiency but also extends to the precise protection of electronic components. This article will focus on the electrostatic protection diode GBLC08CI as a core component and analyze the technological evolution of modern smart dishwashers in the field of circuit protection.

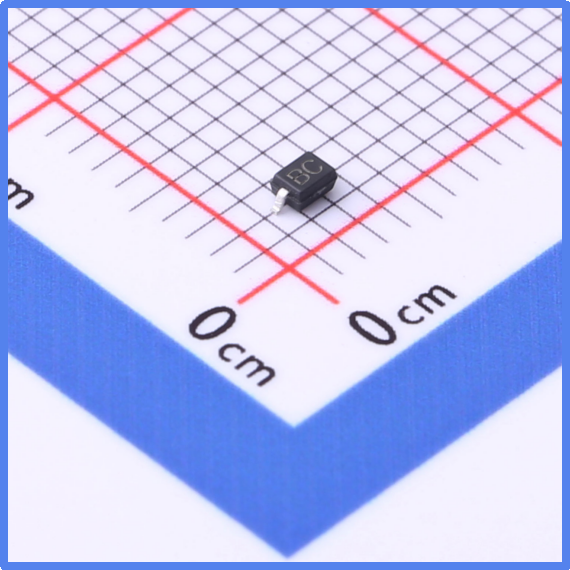

Slkor Electrostatic Discharge Diode GBLC08CI product photo

Contemporary smart dishwashers have evolved beyond the traditional "cleaning dishes" function to form a multi-dimensional technology system that includes smart recognition, precise spraying, and energy-efficient management. With the help of IoT technology, dishwashers can be remotely controlled. Using an array of sensors, they automatically detect grease levels and adjust water pressure dynamically with variable frequency motors. These innovations work together to build a smart kitchen ecosystem. The latest model from a well-known brand even features AI learning capabilities that can remember user habits and optimize washing programs, marking a shift towards proactive, service-oriented smart home appliances.

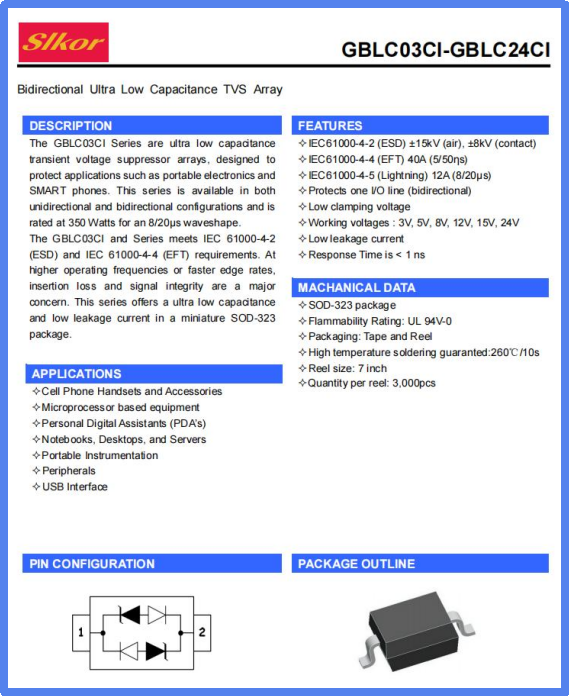

Slkor Electrostatic Discharge Diode GBLC08CI specification

On the hardware front, the integration of electronic components such as touchscreens, wireless communication modules, and precision sensors has significantly increased the complexity of dishwasher circuit systems. According to tests from a certain institution, the component density of modern high-end dishwasher PCBs has increased by 40% compared to five years ago, posing new challenges for circuit protection.

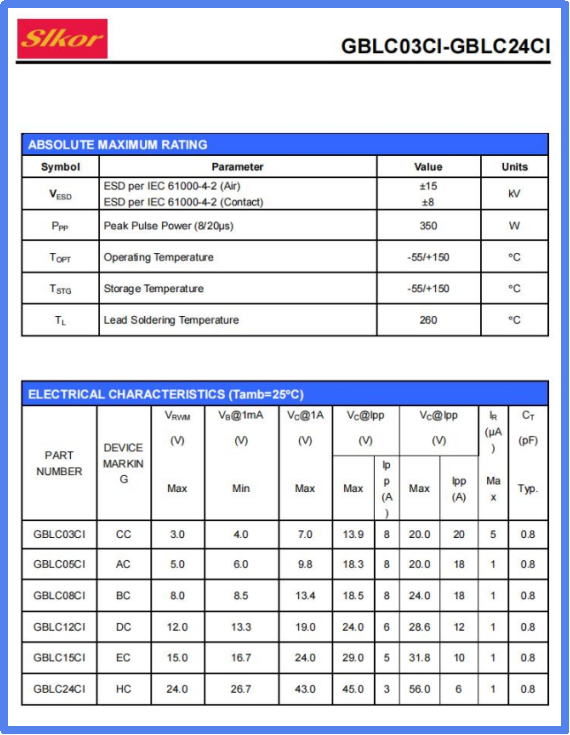

Parameters of Slkor Electrostatic Discharge Diode GBLC08CI

As a new member of the TVS diode family, the GBLC08CI perfectly adapts to high-speed digital circuits with its ultra-low junction capacitance (CJ) of 0.8pF. In USB 2.0 interface protection, this feature ensures signal attenuation remains below 0.5dB, guaranteeing accurate touch command transmission. Its compact SOD-323 packaging (2.5mm × 1.25mm) allows designers to implement multi-channel protection layouts within limited PCB space.

The electrostatic protection performance of this device has been verified through stringent tests: it can withstand contact discharge up to ±8kV and air discharge up to ±15kV under the IEC 61000-4-2 standard. In human body model (HBM) testing, it achieves an ESD protection level of ±8000V. Notably, its unique bidirectional conduction structure can protect against both positive and negative pulse interference, which is especially crucial for dishwashers powered by AC.

In terms of circuit design, the GBLC08CI's 8V reverse working voltage (VRWM) is perfectly compatible with the common 3.3V/5V logic levels used in dishwasher motherboards. When subjected to electrostatic shock, its 18V clamping voltage (VC) safely dissipates excess energy, preventing damage to downstream chips due to overvoltage. With a low leakage current of just 1μA (IR), it ensures standby power consumption remains below 0.1mW, in compliance with EU ErP energy efficiency standards.

Modern dishwasher circuit protection adopts a layered architecture: GBLC08CI is deployed as primary protection at I/O interfaces, while polymer ESD suppressors are used for secondary protection at power entry points, complemented by magnetic beads and inductors to form an LC filter network. This multi-layered protection system gradually attenuates electrostatic energy, with experimental data showing that it improves system-level ESD immunity to ±25kV.

Reliability tests conducted by a manufacturer indicate that dishwashers employing this protection scheme show a deviation of less than 2% in touch response time after 1000 consecutive 8kV electrostatic discharges, with a zero MCU program crash rate—far exceeding the industry average. In salt mist tests, the gold-plated pin design of the GBLC08CI maintained stable contact resistance, ensuring long-term reliability.

With the widespread adoption of 802.11ax Wi-Fi 6 and Bluetooth 5.3 technologies, dishwashers will integrate more wireless communication features, placing higher demands on circuit protection. Next-generation protective components will need to maintain low capacitance characteristics while enhancing suppression capabilities for electromagnetic interference in the 2.4GHz/5GHz frequency bands. It is expected that integrated protection modules will become the trend, further optimizing PCB layout space by combining TVS diodes, filters, and common-mode inductors into a single component.

From mechanical operation to smart connectivity, from basic protection to system-level security, the technological evolution of dishwashers reflects the profound transformation of the home appliance industry towards greater intelligence. The application of new protective components, such as the GBLC08CI, not only builds a safety barrier for electronic systems but also serves as a cornerstone for promoting the healthy development of the smart home ecosystem. In this quiet technological revolution, every small component is contributing to the philosophy of protection in the smart era.

Slkor has research and development offices in Busan, South Korea, Beijing, China, and Suzhou, China. Most of the wafer manufacturing and packaging and testing are carried out within China. The company employs and collaborates with individuals and organizations worldwide, with a laboratory for product performance and reliability testing and a central warehouse located at its headquarters in Shenzhen. Slkor has filed for over a hundred invention patents, offers more than 2,000 product models, and serves over ten thousand customers globally. Its products are exported to countries and regions including Europe, the Americas, Southeast Asia, and the Middle East, making it one of the rapidly growing semiconductor companies in recent years. With well-established management systems and streamlined workflows, Slkor has rapidly enhanced the brand awareness and reputation of its "SLKOR" brand through its outstanding quality and standardized services. Its product range includes three major series: diodes, transistors, and power devices, with recent introductions of new products such as Hall elements and analog devices, expanding its presence in sensors, Risc-v microcontrollers, and other product categories.

Site Map | 萨科微 | 金航标 | Slkor | Kinghelm

RU | FR | DE | IT | ES | PT | JA | KO | AR | TR | TH | MS | VI | MG | FA | ZH-TW | HR | BG | SD| GD | SN | SM | PS | LB | KY | KU | HAW | CO | AM | UZ | TG | SU | ST | ML | KK | NY | ZU | YO | TE | TA | SO| PA| NE | MN | MI | LA | LO | KM | KN

| JW | IG | HMN | HA | EO | CEB | BS | BN | UR | HT | KA | EU | AZ | HY | YI |MK | IS | BE | CY | GA | SW | SV | AF | FA | TR | TH | MT | HU | GL | ET | NL | DA | CS | FI | EL | HI | NO | PL | RO | CA | TL | IW | LV | ID | LT | SR | SQ | SL | UK

Copyright ©2015-2025 Shenzhen Slkor Micro Semicon Co., Ltd