Service hotline

+86 0755-83044319

release time:2025-05-24Author source:SlkorBrowse:593

Driven by the wave of smart homes, kitchen appliances are undergoing a transformation from functional to intelligent. Smart ovens and steam ovens, as the core equipment of modern kitchens, not only meet intelligent needs such as precise temperature control and remote operation, but also face significant challenges in safety and reliability. Behind this technological upgrade, a tiny electrostatic protection diode — the SLSRV05-4, just a few millimeters in diameter — silently safeguards the stable operation of the devices, becoming an indispensable "safety guardian" in the smart kitchen appliance industry.

Slkor Electrostatic Discharge Diode SLSRV05-4 product photo

With the infiltration of IoT technology, modern smart ovens and steam ovens have evolved into complex electronic systems that integrate touch interaction, Wi-Fi/Bluetooth connectivity, sensor arrays, and precision power control. While users enjoy convenient features like voice control, cloud-based recipe downloads, and automatic cooking programs, they are rarely aware that these intelligent features expose the devices to the threat of electrostatic discharge (ESD):

Human-machine interface: Capacitive touch screens tend to accumulate static electricity during finger operation, and static shocks in dry winter environments can reach thousands of volts.

Wireless communication modules: Antenna ports may encounter voltage spikes caused by electromagnetic interference during data transmission.

Power control circuits: The dv/dt noise generated by IGBT module switching may infiltrate the control circuits.

USB/HDMI interfaces: Static pulses generated when external devices are plugged in or unplugged.

These potential threats can lead to device crashes, data loss, or even permanent damage to chips. According to industry statistics, the repair rate of smart home appliances due to electrostatic issues accounts for 12%, resulting in direct economic losses exceeding hundreds of millions each year.

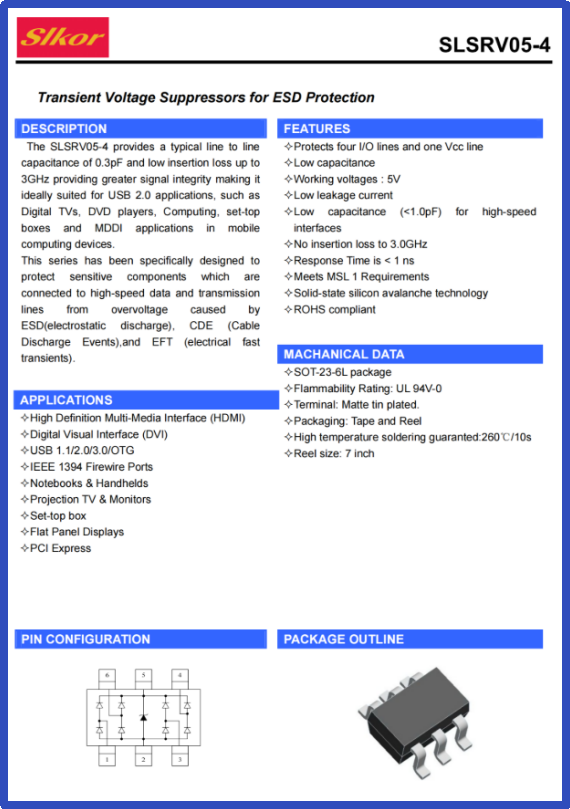

Slkor Electrostatic Discharge Diode SLSRV05-4 specification

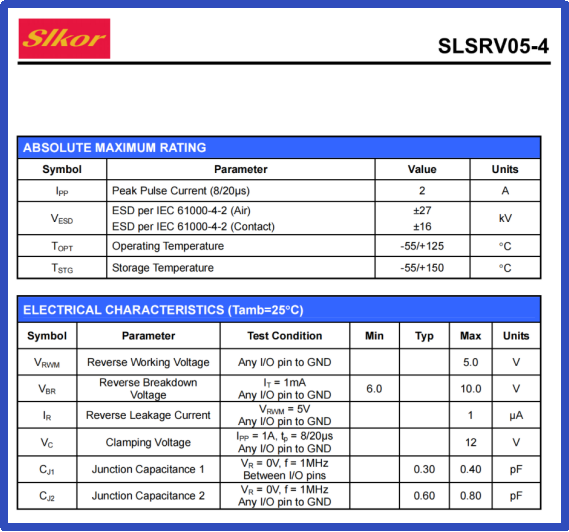

Parameters of Slkor Electrostatic Discharge Diode SLSRV05-4

For the unique working conditions of smart kitchen appliances, the SLSRV05-4 electrostatic protection diode constructs a three-dimensional protection system through six core parameters:

VRWM=5V (Reverse Working Voltage): Precisely matches the operating voltage of 3.3V/5V digital circuits, presenting a high impedance state during normal operation to ensure signal integrity.

VBR≥6V (Breakdown Voltage): When an ESD pulse exceeds the safe threshold, it immediately enters a low-resistance conductive state to form a discharge path.

IR≤1μA (Leakage Current): Ultra-low static power consumption design to avoid impacting the battery life of powered devices.

VC=12V (Clamping Voltage): Limits transient overvoltage to a safe range, protecting downstream CMOS devices from breakdown.

CJ=0.4pF (Junction Capacitance): Extremely low parasitic capacitance ensures high-speed signal transmission without distortion, especially suitable for touch circuit protection.

SOT-23-6 Small Package: 30% smaller than the traditional SOT-23 package, making it suitable for compact PCB layouts.

In a well-known brand's smart steam-and-bake oven, the SLSRV05-4 is deployed at three critical points:

Touch Panel Protection:

Each touch channel is parallel to the SLSRV05-4, and its 0.4pF ultra-low capacitance ensures that the 10-point touch sensitivity is unaffected.

Actual tests show that it can withstand ±8kV contact discharge and ±15kV air discharge according to the IEC 61000-4-2 standard.

Wi-Fi Module Protection:

An LCπ-type filter network is constructed at the 2.4GHz/5GHz dual-frequency antenna ports, with the SLSRV05-4 absorbing high-frequency noise.

Actual test data shows the data transmission error rate drops from 10⁻⁶ before ESD impact to 10⁻⁹.

Power Control Unit:

The diode is deployed between the IGBT driver circuit and MCU, effectively suppressing voltage spikes caused by switching noise.

After accelerated aging tests (1000 hours at 85°C/85% RH), the device's parameter drift is less than 5%.

The large-scale application of the SLSRV05-4 is driving the smart kitchen appliance industry to form new technological competitiveness:

Cost Optimization: A BOM cost increase of $0.08 per unit can reduce 30% of after-sales repair expenses.

Design Simplification: The integrated six-pin package replaces discrete component solutions, saving 40% of PCB area.

Certification Acceleration: Passed international safety certifications such as UL and VDE, shortening the time to market for products overseas.

Experience Upgrade: ESD protection level improved from IEC Class 4 to Class 2, reducing device failure rates by 82%.

In the arms race of smart kitchen appliances, the SLSRV05-4 electrostatic protection diode, with its precise parameter matching and reliable performance, has become the "invisible airbag" of these devices. When consumers remotely start their oven via an app, they may not realize that this tiny component is defending against millions of electrostatic pulses in nanoseconds. On the path to ultimate intelligence, such "silent" foundational technological innovations are building a solid base for the upgrade of China’s kitchen appliance industry.

Slkor has research and development offices in Busan, South Korea, Beijing, China, and Suzhou, China. Most of the wafer manufacturing and packaging and testing are carried out within China. The company employs and collaborates with individuals and organizations worldwide, with a laboratory for product performance and reliability testing and a central warehouse located at its headquarters in Shenzhen. Slkor has filed for over a hundred invention patents, offers more than 2,000 product models, and serves over ten thousand customers globally. Its products are exported to countries and regions including Europe, the Americas, Southeast Asia, and the Middle East, making it one of the rapidly growing semiconductor companies in recent years. With well-established management systems and streamlined workflows, Slkor has rapidly enhanced the brand awareness and reputation of its "SLKOR" brand through its outstanding quality and standardized services. Its product range includes three major series: diodes, transistors, and power devices, with recent introductions of new products such as Hall elements and analog devices, expanding its presence in sensors, Risc-v microcontrollers, and other product categories.

Site Map | 萨科微 | 金航标 | Slkor | Kinghelm

RU | FR | DE | IT | ES | PT | JA | KO | AR | TR | TH | MS | VI | MG | FA | ZH-TW | HR | BG | SD| GD | SN | SM | PS | LB | KY | KU | HAW | CO | AM | UZ | TG | SU | ST | ML | KK | NY | ZU | YO | TE | TA | SO| PA| NE | MN | MI | LA | LO | KM | KN

| JW | IG | HMN | HA | EO | CEB | BS | BN | UR | HT | KA | EU | AZ | HY | YI |MK | IS | BE | CY | GA | SW | SV | AF | FA | TR | TH | MT | HU | GL | ET | NL | DA | CS | FI | EL | HI | NO | PL | RO | CA | TL | IW | LV | ID | LT | SR | SQ | SL | UK

Copyright ©2015-2025 Shenzhen Slkor Micro Semicon Co., Ltd