Service hotline

+86 0755-83044319

release time:2025-05-23Author source:SlkorBrowse:1081

In the Internet of Things (IoT)-driven revolution of smart homes, the smart refrigerator has evolved from a mere food storage device to a central hub for home digitization. As features like touch interaction, AI-driven ingredient management, and wireless connectivity are highly integrated, the reliability of its internal circuits faces a serious challenge from electrostatic discharge (ESD). This paper explores the evolution of protection technologies in smart refrigerator design, using the typical electrostatic protection device RST9361MA as an example.

Slkor Electrostatic Discharge Diode RST9361MA product photo

Modern smart refrigerators achieve environmental awareness through multi-modal sensor arrays, feature high-resolution touchscreens to create human-machine interfaces, integrate Wi-Fi/Bluetooth modules for data exchange, and even incorporate camera systems for food recognition and management. The integration of these advanced electronic systems has been growing exponentially: for example, on the PCB of a flagship model from a major manufacturer, BGA package chips with 0.5mm pitch account for 62%, and the density of high-speed signal transmission lines exceeds 200 lines/cm².

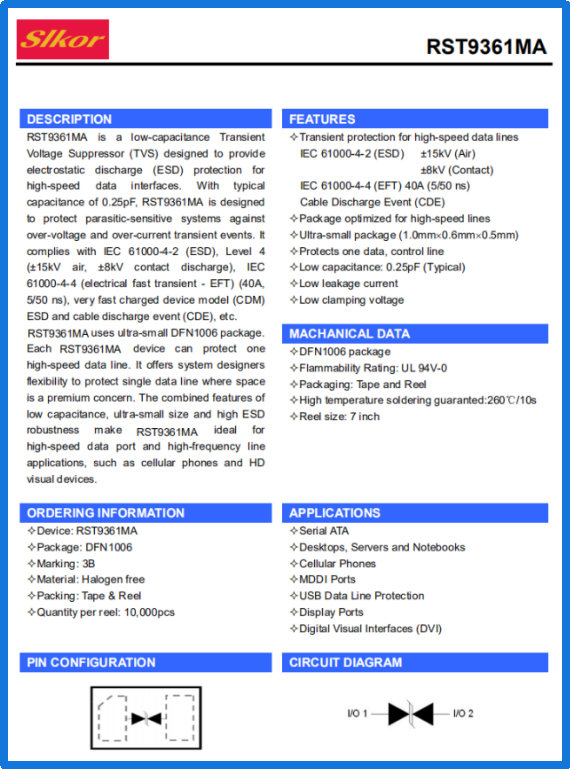

Slkor Electrostatic Discharge Diode RST9361MA specification

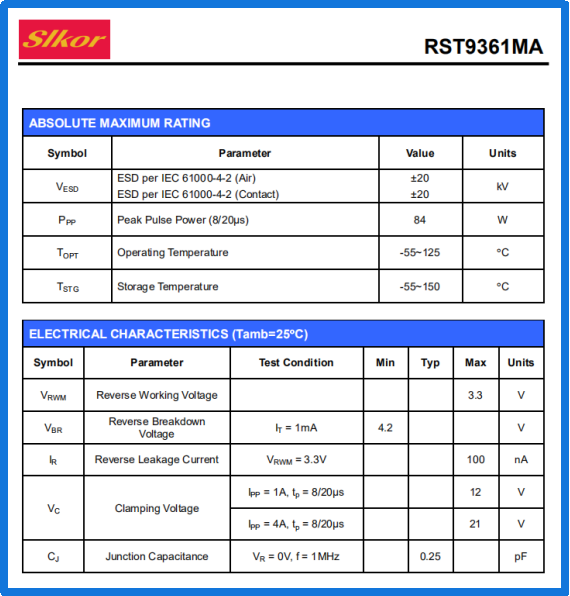

Parameters of Slkor Electrostatic Discharge Diode RST9361MA

This technological intensification brings about dual challenges: on one hand, the probability of electrostatic events (both Human Body Model (HBM) and Machine Model (MM)) increases with the frequency of interaction; on the other hand, the ESD tolerance of chips manufactured with nanometer-scale processes continues to decline. Experimental data shows that when the static voltage exceeds 200V, the failure probability of the main control chip in modern smart refrigerators rises to 37%, while static voltages generated by everyday human activities can reach as high as 8000V.

The RST9361MA is a dedicated electrostatic protection device designed for high-speed interfaces. Its parameters are perfectly suited for the application scenarios of smart refrigerators:

1. Low Capacitance (Cj = 0.25pF): The ultra-low junction capacitance enabled by the DFN1006 package ensures signal integrity for MIPI DSI display interfaces (data rate of 1.5Gbps) and USB 3.1 channels (10Gbps), keeping insertion loss within -0.5dB at 5GHz.

2. Optimized Dynamic Response: With a working voltage (VRWM) of 3.3V, it perfectly matches the I/O levels of the main control chip. At a minimum breakdown voltage (VBR) of 4.2V, it can withstand contact discharge of ±8kV and air discharge of ±15kV as defined by the IEC 61000-4-2 standard.

3. Energy Handling Capacity: With a clamping voltage (VC) of 12V at 1A and a verified 3A pulse current handling capacity via TLP testing, it effectively protects HDMI 2.1 interfaces (48Gbps) from EFT (electrical fast transient) interference.

4. Low Leakage Design: A reverse leakage current (IR) of 100nA ensures that power consumption in standby mode is only 0.33μW, meeting the EU ErP directive’s requirement for smart appliances to have standby power consumption of less than 0.5W.

In the circuit design of the smart refrigerator, the RST9361MA is deployed at three key nodes:

1. Human-Machine Interface Protection: A bidirectional symmetric layout is used at the FPC connector of the touch screen, along with a TVS array to create a two-level protection system. Experimental data shows that this approach delays the impact of ESD on the touch controller from 2ns to 15ns, allowing sufficient time for MCU response.

2. Wireless Communication Module Isolation: At the antenna feed point of the Wi-Fi/Bluetooth module, the RST9361MA in 0201 size is used for differential pair protection. It keeps the insertion loss fluctuation of the 2.4GHz band within ±0.2dB, ensuring that the -95dBm receive sensitivity remains unaffected.

3. Power System Clamping: A π-type filtering network is built at the input of the DC-DC converter, combined with the RST9361MA's fast response characteristics (response time <1ns) to suppress transient voltage spikes on the power rail below the safe threshold.

Accelerated life testing shows that after continuous operation for 2000 hours in an 85°C/85%RH environment, the leakage current of the RST9361MA increases by less than 5%, and its capacitance drift is less than 0.03pF, meeting the 10-year lifespan requirement for smart refrigerators. In EMC testing, the prototype with this device successfully passed the CISPR 32 Class B radiated emission test, with radiation intensity in the 30MHz-1GHz range reduced by 12-18dBμV/m compared to the unprotected state.

With the application of third-generation semiconductor materials, SiC-based electrostatic protection devices are showing superior performance in laboratory settings. Theoretical calculations suggest that silicon carbide-based devices can achieve junction capacitances in the 0.1pF range and withstand di/dt capabilities of 500V/ns. This points to a future where the protection solutions for smart refrigerators will evolve towards higher integration and lower loss, supporting emerging applications like 8K video transmission and UWB precise positioning.

On the evolutionary track of smart homes, basic devices like the RST9361MA are building the security barrier for digital living through technological innovation. When every line of code, every photo, and every instance of ingredient recognition is shielded from electrostatic threats, the smart refrigerator can truly become a trusted digital steward for the home. This micro-level technological breakthrough is the key force driving a macro-level shift in product experience.

Slkor has research and development offices in Busan, South Korea, Beijing, China, and Suzhou, China. Most of the wafer manufacturing and packaging and testing are carried out within China. The company employs and collaborates with individuals and organizations worldwide, with a laboratory for product performance and reliability testing and a central warehouse located at its headquarters in Shenzhen. Slkor has filed for over a hundred invention patents, offers more than 2,000 product models, and serves over ten thousand customers globally. Its products are exported to countries and regions including Europe, the Americas, Southeast Asia, and the Middle East, making it one of the rapidly growing semiconductor companies in recent years. With well-established management systems and streamlined workflows, Slkor has rapidly enhanced the brand awareness and reputation of its "SLKOR" brand through its outstanding quality and standardized services. Its product range includes three major series: diodes, transistors, and power devices, with recent introductions of new products such as Hall elements and analog devices, expanding its presence in sensors, Risc-v microcontrollers, and other product categories.

Site Map | 萨科微 | 金航标 | Slkor | Kinghelm

RU | FR | DE | IT | ES | PT | JA | KO | AR | TR | TH | MS | VI | MG | FA | ZH-TW | HR | BG | SD| GD | SN | SM | PS | LB | KY | KU | HAW | CO | AM | UZ | TG | SU | ST | ML | KK | NY | ZU | YO | TE | TA | SO| PA| NE | MN | MI | LA | LO | KM | KN

| JW | IG | HMN | HA | EO | CEB | BS | BN | UR | HT | KA | EU | AZ | HY | YI |MK | IS | BE | CY | GA | SW | SV | AF | FA | TR | TH | MT | HU | GL | ET | NL | DA | CS | FI | EL | HI | NO | PL | RO | CA | TL | IW | LV | ID | LT | SR | SQ | SL | UK

Copyright ©2015-2025 Shenzhen Slkor Micro Semicon Co., Ltd