Service hotline

+86 0755-83044319

release time:2025-05-23Author source:SlkorBrowse:606

In the Internet of Things (IoT)-driven smart home revolution, smart washing machines have evolved from traditional household appliances into the core of home health management. When features like spray washing, AI-powered weight sensing, and IoT connectivity are highly integrated, the reliability of the internal circuits faces the daunting challenge of electrostatic discharge (ESD). This paper examines the evolution of protection technology in smart washing machine design, using the typical ESD protection component SLPESD0603-07 as a case study.

Slkor Electrostatic Discharge Diode SLPESD0603-07 product photo

Modern smart washing machines utilize multimodal sensor arrays for fabric recognition, incorporate high-pressure spraying systems to enhance cleaning efficiency, and integrate Wi-Fi modules for remote control, along with touchscreens for human-machine interaction. The integration of these precision electronic systems has grown exponentially: in the flagship model from a major manufacturer, BGA packaged chips with a 0.4mm pitch occupy 58% of the PCB, and the density of high-speed signal transmission lines exceeds 180 lines/cm².

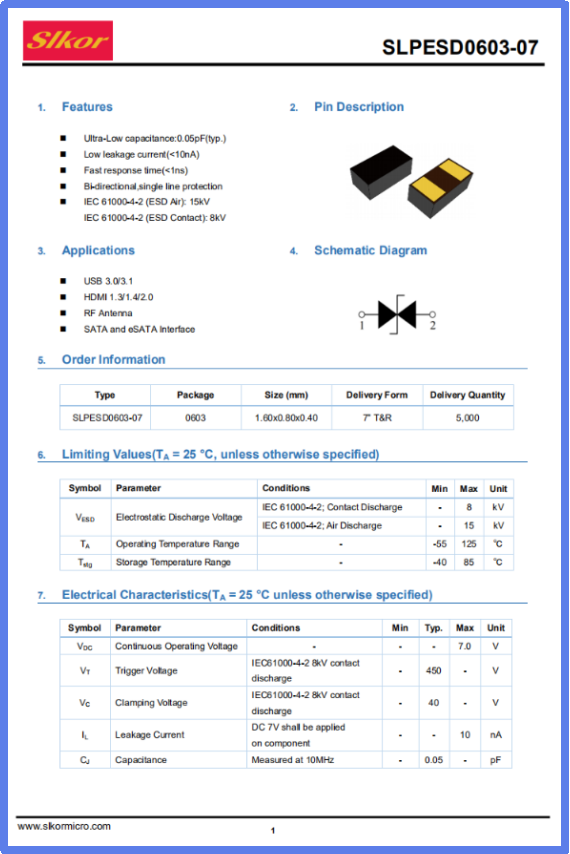

Slkor Electrostatic Discharge Diode SLPESD0603-07 specification

This technological intensification presents two major challenges: On one hand, the frequency of electrostatic events due to human body contact (HBM) and machine modes (MM) increases with the frequency of interactions; on the other hand, the electrostatic discharge (ESD) resistance of chips fabricated with nanometer processes continues to decrease. Experimental data shows that when the static voltage exceeds 150V, the failure probability of modern washing machine control chips rises dramatically to 41%, while static voltages generated by normal human activities can reach up to 8000V.

Parameters of Slkor Electrostatic Discharge Diode SLPESD0603-07

The SLPESD0603-07, designed specifically for industrial interfaces, has a parameter configuration that precisely matches the application scenarios of smart washing machines:

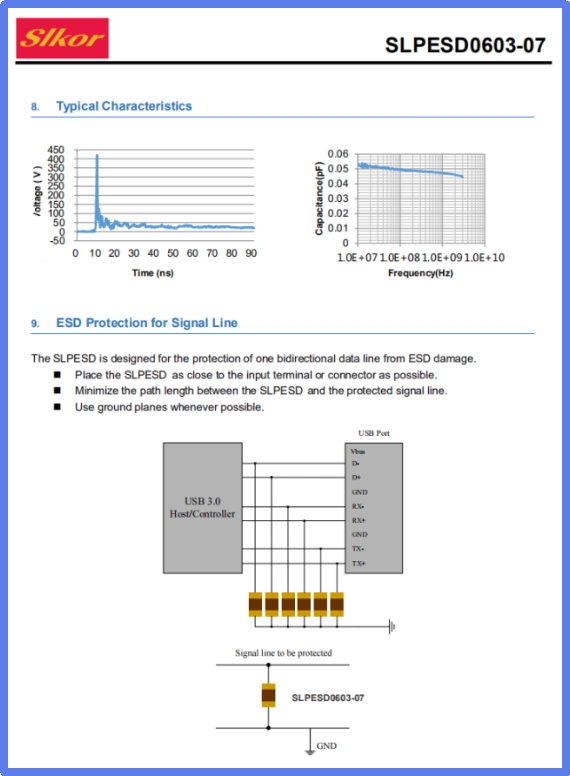

1. Ultra-Low Capacitance (Cj=0.05pF): The ultra-low junction capacitance achieved by the SATA package ensures signal integrity for MIPI DSI display interfaces (data rate 1.2Gbps) and USB 3.0 channels (5Gbps), keeping insertion loss within -0.3dB@4GHz.

2. Dynamic Response Optimization: With a working voltage (VRWM) of 8V, it perfectly matches the I/O levels of the main control chip. It can withstand ±15kV contact discharge and ±25kV air discharge impacts, meeting the IEC 61000-4-2 standard with a minimum breakdown voltage (VBR) of 15V.

3. Energy Handling Capability: The 40V clamping voltage (VC) and 5A pulse current handling capacity, verified by TLP testing, effectively protect HDMI 2.0 interfaces (18Gbps) from EFT (electrical fast transient) interference.

4. Ultra-Low Leakage Design: With a reverse leakage current (IR) of 10nA, the power consumption in standby mode is only 0.08μW, complying with the EU ErP directive for smart home appliances with standby power consumption <0.5W.

In the circuit design of smart washing machines, the SLPESD0603-07 is deployed at three critical nodes:

1. IoT Communication Module Protection: At the antenna feed of the Wi-Fi/Bluetooth module, the 0402-sized SLPESD0603-07 provides differential pair protection, controlling insertion loss fluctuations in the 2.4GHz band to within ±0.1dB, ensuring that the reception sensitivity of -92dBm remains unaffected.

2. High-Voltage Power Supply Clamping: At the input of the Power Factor Correction (PFC) circuit, a π-type filtering network is constructed, along with the SLPESD0603-07’s fast response characteristics (response time <0.8ns), which suppresses transient voltage spikes on the power rails to below safe thresholds.

3. Human-Machine Interface Protection: At the FPC connector of the touchscreen, a bidirectional symmetric layout, combined with a TVS array, creates a two-tier protection system. Test results show that this approach extends the ESD impact delay on the touch controller from 1.8ns to 14ns, giving the MCU sufficient time to respond.

With the application of Gallium Nitride (GaN) materials, GaN-based electrostatic protection components are showing superior performance in laboratory stages. Theoretical calculations suggest that GaN-based devices can achieve junction capacitance at the 0.01pF level and withstand di/dt rates of up to 800V/ns. This suggests that future smart washing machine protection solutions will evolve toward higher integration and lower loss, supporting emerging applications like 8K video transmission and UWB precise positioning.

In the evolutionary path of smart homes, fundamental components like the SLPESD0603-07 are building the safety barriers for the digital lifestyle through technological innovation. When every line of code, every image, and every smart wash cycle is protected from electrostatic threats, the smart washing machine will truly become a trusted home health steward. These microscopic technological breakthroughs are the key force driving the macro-level transformation of product experience.

Slkor has research and development offices in Busan, South Korea, Beijing, China, and Suzhou, China. Most of the wafer manufacturing and packaging and testing are carried out within China. The company employs and collaborates with individuals and organizations worldwide, with a laboratory for product performance and reliability testing and a central warehouse located at its headquarters in Shenzhen. Slkor has filed for over a hundred invention patents, offers more than 2,000 product models, and serves over ten thousand customers globally. Its products are exported to countries and regions including Europe, the Americas, Southeast Asia, and the Middle East, making it one of the rapidly growing semiconductor companies in recent years. With well-established management systems and streamlined workflows, Slkor has rapidly enhanced the brand awareness and reputation of its "SLKOR" brand through its outstanding quality and standardized services. Its product range includes three major series: diodes, transistors, and power devices, with recent introductions of new products such as Hall elements and analog devices, expanding its presence in sensors, Risc-v microcontrollers, and other product categories.

Site Map | 萨科微 | 金航标 | Slkor | Kinghelm

RU | FR | DE | IT | ES | PT | JA | KO | AR | TR | TH | MS | VI | MG | FA | ZH-TW | HR | BG | SD| GD | SN | SM | PS | LB | KY | KU | HAW | CO | AM | UZ | TG | SU | ST | ML | KK | NY | ZU | YO | TE | TA | SO| PA| NE | MN | MI | LA | LO | KM | KN

| JW | IG | HMN | HA | EO | CEB | BS | BN | UR | HT | KA | EU | AZ | HY | YI |MK | IS | BE | CY | GA | SW | SV | AF | FA | TR | TH | MT | HU | GL | ET | NL | DA | CS | FI | EL | HI | NO | PL | RO | CA | TL | IW | LV | ID | LT | SR | SQ | SL | UK

Copyright ©2015-2025 Shenzhen Slkor Micro Semicon Co., Ltd