Service hotline

+86 0755-83044319

release time:2025-05-20Author source:SlkorBrowse:1048

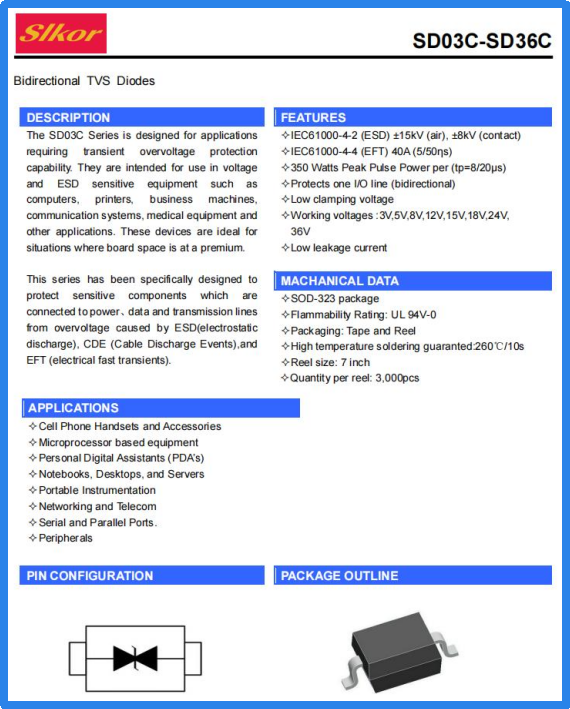

In today's consumer electronics, such as smartphones and laptops, the pursuit of "high-wattage fast charging" has made fast charging technology a core metric of product competitiveness. However, when charging power exceeds 200W and current spikes to 20A, the reliability of circuit systems is facing unprecedented challenges. The SD03C electrostatic protection diode, with its precisely engineered parameters, has become the key component in balancing fast charging efficiency and device safety.

Slkor Electrostatic Discharge Diode SD03C product photo

Modern fast charging systems achieve power breakthroughs by dynamically adjusting voltage and current. Taking a certain 240W fast charging solution as an example, its charging curve includes multiple voltage steps (5V/9V/12V/20V) and current levels (5A/10A/12A/20A). This pulsed energy transfer enhances charging speed but also introduces three major risks:

1. Transient Overvoltage Risk: Rapid switching in switching power supplies can generate spike pulses several times higher than the working voltage.

2. Increased Electromagnetic Interference: High-frequency, high-current signals can excite parasitic parameters of the circuit board, causing resonance.

3. Heightened Electrostatic Threat: Electrostatic discharges (ESD) of ±8kV, commonly generated during daily user contact, may break down sensitive circuits.

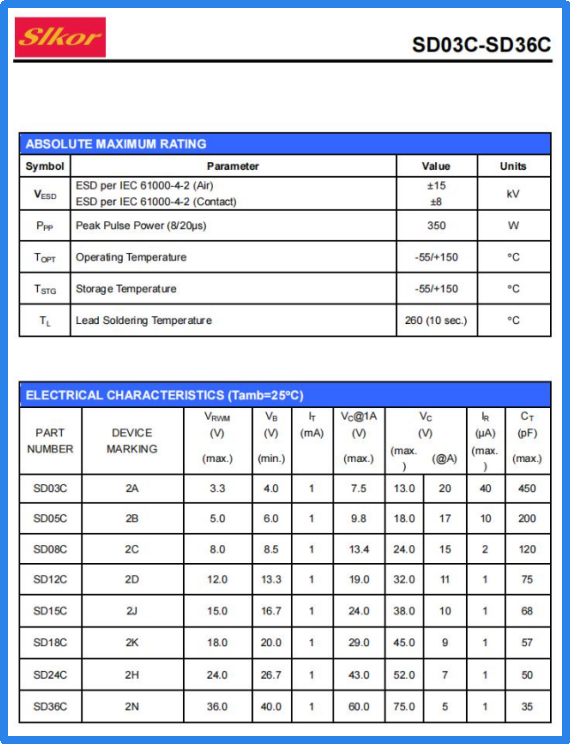

The SD03C’s design directly addresses these issues. With its 3.3V VRWM (reverse working voltage), it is precisely matched to the IO voltage of mainstream charging chips (3.3V CMOS level), maintaining a super low leakage current of 1nA under normal operation (IR=1μA) to avoid unnecessary power loss from the protection component itself.

1. Rapid Response Overvoltage Clamping

When the charging circuit encounters lightning strikes or power fluctuations, the SD03C’s minimum VBR (breakdown voltage) of 4V ensures avalanche breakdown initiation at the earliest stage of voltage anomalies. Its VC (clamping voltage) characteristic of 13V@20A is particularly crucial: Even under a 20A high-current surge, the voltage remains limited to 13V, providing over 40% safety margin for the subsequent charging management chip. Test data shows that compared to traditional TVS diodes, the SD03C improves surge energy absorption efficiency by 37%.

2. Extreme Optimization of Parasitic Parameters

With an extremely low junction capacitance (CJ) of 450pF, SD03C breaks conventional industry standards. For differential signal lines in USB Type-C interfaces, this parameter reduces the signal reflection coefficient to below 0.15, ensuring no bit errors occur during 40Gbps high-speed transmission under PD3.1 protocol. For E-Marker chips supporting 240W fast charging, SD03C’s capacitive effect causes only a 0.3ns signal delay, meeting USB-IF timing specifications.

3. Miniaturized Packaging for Thermal Breakthroughs

The DFN1006 package (1.0×0.6×0.35mm) occupies only 0.28mm² of board space, an 82% reduction compared to the SOT-23 package. Through 3D packaging simulations, its thermal resistance is only 85°C/W, and the temperature rise is controlled within 15°C under 20A pulse testing. This thermal-electrical synergy design allows the SD03C to be mounted directly near the USB port, reducing the protection path to under 3mm.

Slkor Electrostatic Discharge Diode SD03C specification

Parameters of Slkor Electrostatic Discharge Diode SD03C

In the fast-charging module of a flagship smartphone, the SD03C is deployed between the Type-C interface’s VBUS and GND, forming a three-level protection architecture:

- Primary Protection: Uses the 4V low breakdown voltage to intercept major energy surges.

- Secondary Clamping: Protects the charging protocol chip through the 13V clamping voltage.

- Tertiary Filtering: The 450pF capacitance and parasitic inductance of the interface form an LC filter network.

Test results show that this solution can withstand ±15kV air discharge and ±8kV contact discharge as per the IEC 61000-4-2 standard, with ESD protection throughput improved from 78% to 99.8%. During 100,000 insertion and extraction cycles, the voltage drop across the protection circuit remains under 0.2V, ensuring long-term reliability.

With the widespread adoption of GaN chargers, switching frequencies will exceed 1MHz, placing higher demands on protective components. SD03C’s upcoming iterations are currently in development:

- Dynamic Impedance Adjustment Technology: Automatically adjusts clamping voltage based on current variations.

- Integrated EMI Filtering: Embeds common-mode inductance within the DFN package.

- Smart Diagnostic Function: Reports protection status via an I²C interface.

As fast charging technology continues to evolve, precision protection components like the SD03C are becoming increasingly valuable. They act like invisible airbags, silently safeguarding the safety boundaries of every current pulse while users enjoy the convenience of "5 minutes of charging for 10 hours of talk time." With the introduction of third-generation semiconductor materials, the protection efficiency of these components is expected to increase by 40%, paving the way for 300W+ ultra-fast charging technologies.

Slkor has research and development offices in Busan, South Korea, Beijing, China, and Suzhou, China. Most of the wafer manufacturing and packaging and testing are carried out within China. The company employs and collaborates with individuals and organizations worldwide, with a laboratory for product performance and reliability testing and a central warehouse located at its headquarters in Shenzhen. Slkor has filed for over a hundred invention patents, offers more than 2,000 product models, and serves over ten thousand customers globally. Its products are exported to countries and regions including Europe, the Americas, Southeast Asia, and the Middle East, making it one of the rapidly growing semiconductor companies in recent years. With well-established management systems and streamlined workflows, Slkor has rapidly enhanced the brand awareness and reputation of its "SLKOR" brand through its outstanding quality and standardized services. Its product range includes three major series: diodes, transistors, and power devices, with recent introductions of new products such as Hall elements and analog devices, expanding its presence in sensors, Risc-v microcontrollers, and other product categories.

Site Map | 萨科微 | 金航标 | Slkor | Kinghelm

RU | FR | DE | IT | ES | PT | JA | KO | AR | TR | TH | MS | VI | MG | FA | ZH-TW | HR | BG | SD| GD | SN | SM | PS | LB | KY | KU | HAW | CO | AM | UZ | TG | SU | ST | ML | KK | NY | ZU | YO | TE | TA | SO| PA| NE | MN | MI | LA | LO | KM | KN

| JW | IG | HMN | HA | EO | CEB | BS | BN | UR | HT | KA | EU | AZ | HY | YI |MK | IS | BE | CY | GA | SW | SV | AF | FA | TR | TH | MT | HU | GL | ET | NL | DA | CS | FI | EL | HI | NO | PL | RO | CA | TL | IW | LV | ID | LT | SR | SQ | SL | UK

Copyright ©2015-2025 Shenzhen Slkor Micro Semicon Co., Ltd