Service hotline

+86 0755-83044319

release time:2025-05-19Author source:SlkorBrowse:1094

In the field of precision manufacturing, CNC machines are considered the industrial backbone, where their processing accuracy directly determines the performance limits of high-end components. As spindle speeds break through 200,000 RPM and processing precision moves toward the nano-scale, the sensitivity of the machine’s internal electronic control systems to electrostatic discharge (ESD) rises exponentially. The ESD protection diode SLESD5.0U035, with its outstanding performance parameters, has become an invisible guardian ensuring the stable operation of precision CNC machines.

Slkor Electrostatic Discharge Diode SLESD5.0U035 product photo

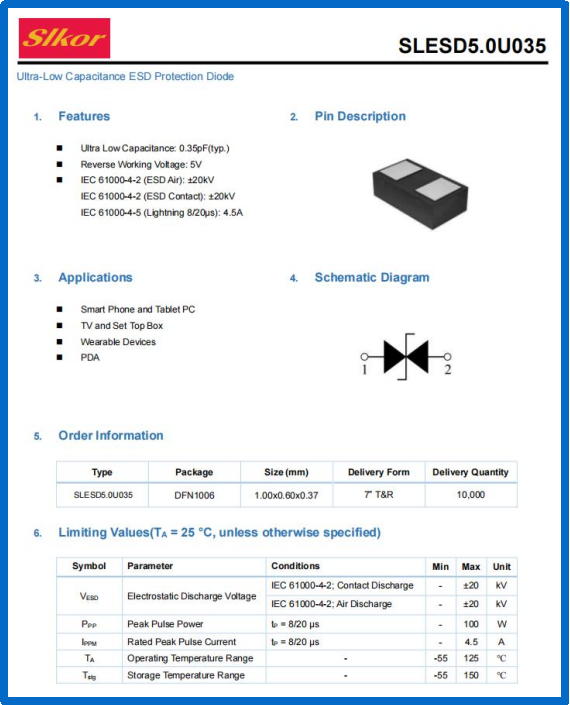

The technical specifications of the SLESD5.0U035 are designed with careful consideration of the unique operating conditions in precision CNC machines. Its 5V reverse working voltage (VRWM) is perfectly compatible with the low-voltage circuits of the machine’s servo drivers and CNC control systems. In normal operation, it presents a high-impedance state, with a leakage current as low as 0.1μA, contributing minimal additional load to the circuit. When the electrostatic voltage exceeds the minimum breakdown voltage (VBR min) of 6V, the diode instantly conducts, limiting the clamping voltage (VC) to 11V. This safety threshold effectively dissipates static electricity without surpassing the tolerance limit of the core chip in the CNC system.

Slkor Electrostatic Discharge Diode SLESD5.0U035 specification

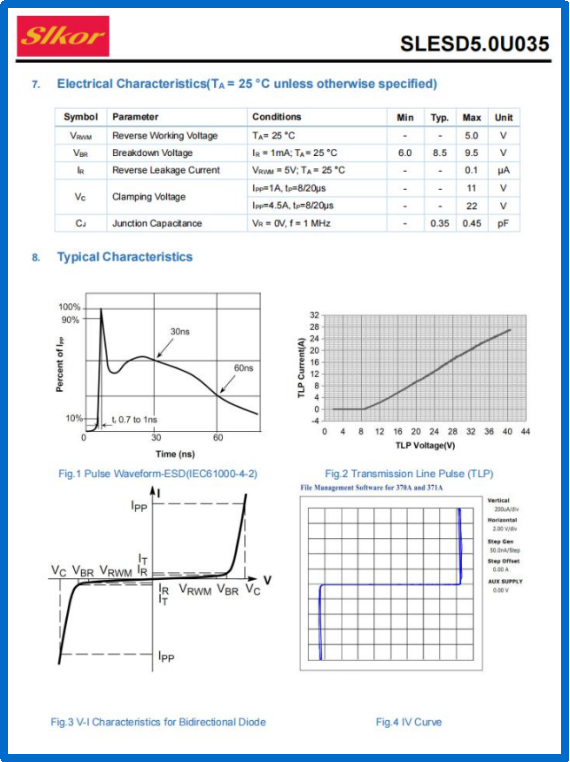

Slkor Electrostatic Discharge Diode SLESD5.0U035 specification

The extremely low junction capacitance (CJ) of 0.45pF is critical for high-speed signal transmission. In CNC machines with five-axis simultaneous control, the servo drive signal frequencies can reach MHz levels. This parameter ensures the integrity of high-frequency signals such as position encoder feedback and motor control pulses. The miniature DFN1006 package (only 1.0mm × 0.6mm × 0.37mm) offers significant space-saving advantages, enabling precise mounting even within the tight spaces of compact circuit boards and motor drive modules in CNC machines.

Parameters of Slkor Electrostatic Discharge Diode SLESD5.0U035

Parameters of Slkor Electrostatic Discharge Diode SLESD5.0U035

In the field of precision CNC machines, the SLESD5.0U035 has become the standard protection component for critical modules like control systems, servo drives, and precision sensors. For example, a certain five-axis machining center used in aerospace blade manufacturing experienced frequent malfunctions in the three-axis servo driver due to electrostatic charges generated by the friction between cutting fluid and workpieces. After installing this diode, tests by the China Electronics Technology Standardization Institute showed that the RS-485 communication interface’s electrostatic discharge (ESD) tolerance improved to ±8kV contact discharge according to IEC 61000-4-2 standards, resulting in an 89% reduction in failure rates. For the machine’s spindle encoder interface, products with a junction capacitance of only 0.15pF ensured that the 1Vpp differential signal transmission error remained below 0.1%.

In terms of protecting precision sensors, a specific ultra-precision lathe used in optical component processing had issues with laser interferometer measurement data fluctuations due to electrostatic buildup from environmental dust. After paralleling the SLESD5.0U035 in the sensor signal conditioning circuit, real-world tests showed that it could withstand ±6kV contact discharge, restoring displacement measurement accuracy to ±0.02μm. For CNC system buses in machine tools, this device, in combination with a TVS diode, formed a composite protection solution. In tests at a mold-making company in Shenzhen, it successfully prevented 95% of Ethernet/IP bus communication disruptions.

As precision CNC machines evolve into smart factories, ESD protection solutions are following three key trends: integrated design, which combines multiple protection channels within the DFN1006 package—such as a 4-channel product from a certain manufacturer, reducing PCB area by 70% compared to discrete solutions; intelligent protection that incorporates machine learning algorithms to dynamically adjust clamping voltage based on real-time monitoring of electrostatic events; and material innovation, where the use of third-generation semiconductor materials has enabled device conduction speeds to exceed 0.5ns while maintaining a lifetime of over 10^12 impacts.

In mass production data from a CNC group in Shenyang, the use of the SLESD5.0U035 series products reduced the annual repair rate of equipment from 2.8% to 0.6%, cutting the lifecycle maintenance cost of a single unit by $38. These real-world data demonstrate the critical role that electrostatic protection devices play in supporting the commercial value of precision CNC machines. With the advent of the AIoT era, foundational components like the SLESD5.0U035 will continue to bridge the gap between machine tool intelligence and reliability.

Site Map | 萨科微 | 金航标 | Slkor | Kinghelm

RU | FR | DE | IT | ES | PT | JA | KO | AR | TR | TH | MS | VI | MG | FA | ZH-TW | HR | BG | SD| GD | SN | SM | PS | LB | KY | KU | HAW | CO | AM | UZ | TG | SU | ST | ML | KK | NY | ZU | YO | TE | TA | SO| PA| NE | MN | MI | LA | LO | KM | KN

| JW | IG | HMN | HA | EO | CEB | BS | BN | UR | HT | KA | EU | AZ | HY | YI |MK | IS | BE | CY | GA | SW | SV | AF | FA | TR | TH | MT | HU | GL | ET | NL | DA | CS | FI | EL | HI | NO | PL | RO | CA | TL | IW | LV | ID | LT | SR | SQ | SL | UK

Copyright ©2015-2025 Shenzhen Slkor Micro Semicon Co., Ltd