Service hotline

+86 0755-83044319

release time:2025-05-26Author source:SlkorBrowse:5225

As air pollution becomes an increasingly pressing issue, smart air purifiers have become essential devices in modern homes and workplaces. Their evolution focuses not only on improving filtration efficiency but also on advancements in sensor accuracy, smart interactions, and hardware reliability. This article takes a smart air purifier equipped with the electrostatic protection diode GBLC15CI as an example to analyze its technological architecture and the collaborative function of its core components.

Slkor Electrostatic Discharge Diode GBLC15CI product photo

1. Multidimensional Sensing and Precision Control

Modern smart air purifiers build an environmental sensing network using laser dust sensors, VOC gas sensors, and temperature and humidity modules. For instance, one flagship model boasts a PM2.5 detection precision of up to 0.3μg/m³. Combined with AI algorithms, it dynamically adjusts fan speed and filter modes. This real-time responsiveness demands exceptional circuit stability, as sensor signals are highly susceptible to electromagnetic interference, and the stable operation of the main control chip directly impacts user experience.

2. Efficient Filtration and Low-Noise Design

The composite structure of HEPA filters and activated carbon layers achieves a 99.97% particle interception rate, but electrostatic accumulation from high-speed airflow can pose a risk. One model addresses this by adding an ion fan at the circuit board’s entry point to neutralize filter static, while still providing secondary protection for sensitive components.

3. Internet of Things (IoT) and Interaction Upgrades

Features like dual-mode Wi-Fi/Bluetooth connectivity, voice control, and remote operation via apps make air purifiers an integral part of the smart home ecosystem. However, the complexity of communication protocols increases the risk of circuit damage from ESD (electrostatic discharge), especially in dry environments or when the device is in direct contact with users.

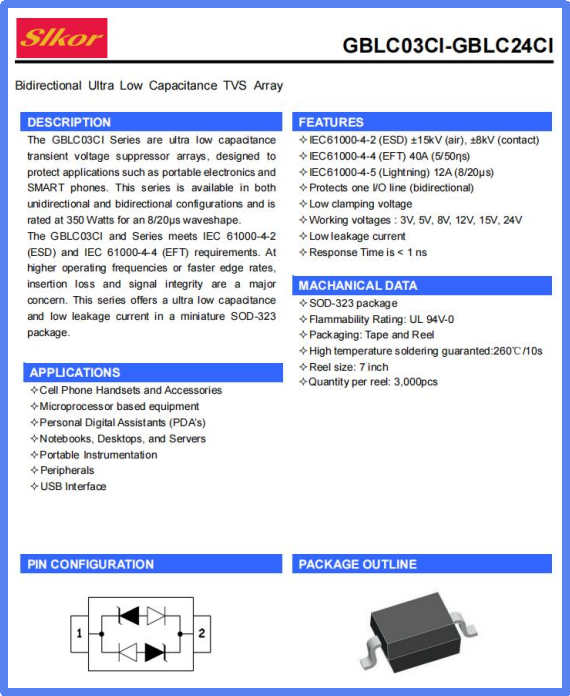

Slkor Electrostatic Discharge Diode GBLC15CI specification

As a key component in circuit protection, the GBLC15CI diode has become the preferred choice for high-end purifiers due to its outstanding performance. Its technical specifications directly address protection needs:

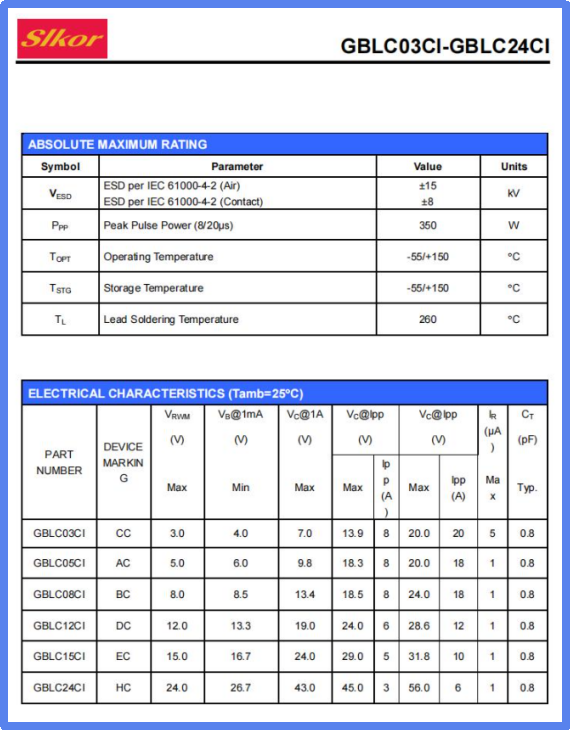

- VRWM (Maximum Working Voltage): 15V, suitable for low-voltage digital circuits.

- VBR min (Minimum Breakdown Voltage): 16.7V, accurately balancing response speed and false triggering.

- IR (Reverse Leakage Current): 1μA, extremely low leakage current reduces static power consumption.

- VC (Clamping Voltage): 24V, limits transient overvoltage energy.

- CJ (Junction Capacitance): 0.8pF, ultra-low junction capacitance ensures signal integrity.

- Package: SOD-323, a compact package suitable for high-density PCB layouts.

Parameters of Slkor Electrostatic Discharge Diode GBLC15CI

1. Precision Protection Logic

When the device’s casing is touched or an ESD pulse from lightning strikes, the GBLC15CI can clamp the voltage to 24V within 1ns, preventing damage to the main control chip’s I/O ports (typically rated for 5.5V). Its 16.7V breakdown voltage prevents false triggering while ensuring effective protection even under 15kV air discharge.

2. Signal Integrity Protection

With a junction capacitance of just 0.8pF, the diode can be parallel-connected at both ends of high-speed data lines (e.g., USB 3.0), limiting signal attenuation to less than 1dB. In the purifier's communication module, this feature ensures stable real-time uploading of temperature and humidity data.

3. Space and Energy Efficiency Optimization

The SOD-323 package (2.5mm×1.35mm) allows the diode to be mounted directly near sensor interfaces, shortening trace lengths and reducing parasitic inductance. With a leakage current of just 1μA, the diode consumes only 0.00876Wh of energy over a year of operation (8760 hours), meeting the first-tier energy efficiency standards for air purifiers.

Taking the power management module of a specific purifier as an example, the GBLC15CI is deployed at three critical points:

1. Power Input: Parallel to the DC-DC converter’s front stage to suppress surges caused by power grid fluctuations.

2. Sensor Interface: Protects the analog signal lines of the PM2.5 laser module to prevent data fluctuations.

3. Communication Interface: Provides ESD protection for the RF circuit of the Wi-Fi chip, maintaining a -95dBm reception sensitivity.

In IEC 61000-4-2 standard testing, this solution successfully withstood 8kV contact discharge and 15kV air discharge, with a device recovery time of less than 100ms, well below the industry standard of 500ms.

With the application of gallium nitride (GaN) materials in power modules, the working voltage of circuits will further decrease, placing higher demands on the response speed and clamping accuracy of protection devices. Additionally, the integration of wearable devices with air purifiers could drive the development of composite components that combine ESD protection and EMI filtering.

The evolution of smart air purifiers is essentially the deep integration of electronic technology and environmental science. From the physical interception of particles by HEPA filters to electrostatic protection by GBLC15CI diodes, every technological detail is aimed at creating a safer, smarter breathing solution. When technological innovation truly serves human health, even the cold components are imbued with warm value.

Slkor has research and development offices in Busan, South Korea, Beijing, China, and Suzhou, China. Most of the wafer manufacturing and packaging and testing are carried out within China. The company employs and collaborates with individuals and organizations worldwide, with a laboratory for product performance and reliability testing and a central warehouse located at its headquarters in Shenzhen. Slkor has filed for over a hundred invention patents, offers more than 2,000 product models, and serves over ten thousand customers globally. Its products are exported to countries and regions including Europe, the Americas, Southeast Asia, and the Middle East, making it one of the rapidly growing semiconductor companies in recent years. With well-established management systems and streamlined workflows, Slkor has rapidly enhanced the brand awareness and reputation of its "SLKOR" brand through its outstanding quality and standardized services. Its product range includes three major series: diodes, transistors, and power devices, with recent introductions of new products such as Hall elements and analog devices, expanding its presence in sensors, Risc-v microcontrollers, and other product categories.

Site Map | 萨科微 | 金航标 | Slkor | Kinghelm

RU | FR | DE | IT | ES | PT | JA | KO | AR | TR | TH | MS | VI | MG | FA | ZH-TW | HR | BG | SD| GD | SN | SM | PS | LB | KY | KU | HAW | CO | AM | UZ | TG | SU | ST | ML | KK | NY | ZU | YO | TE | TA | SO| PA| NE | MN | MI | LA | LO | KM | KN

| JW | IG | HMN | HA | EO | CEB | BS | BN | UR | HT | KA | EU | AZ | HY | YI |MK | IS | BE | CY | GA | SW | SV | AF | FA | TR | TH | MT | HU | GL | ET | NL | DA | CS | FI | EL | HI | NO | PL | RO | CA | TL | IW | LV | ID | LT | SR | SQ | SL | UK

Copyright ©2015-2025 Shenzhen Slkor Micro Semicon Co., Ltd