Service hotline

+86 0755-83044319

release time:2025-05-26Author source:SlkorBrowse:5110

Driven by the wave of smart home technology, smart vacuum robots have become the core device for floor cleaning in modern households. From the early “artificially unintelligent” models that randomly collided with objects to the current robots capable of autonomous decision-making, their technological evolution is not only reflected in breakthroughs in navigation algorithms and mechanical structures but also in underlying technologies such as circuit protection. This article will focus on the SD05C electrostatic protection diode and analyze its key role in vacuum robots.

Slkor Electrostatic Discharge Diode SD05C product photo

Modern vacuum robots have surpassed the role of a single cleaning tool and evolved into multifunctional service robots. Trifo's bionic multi-joint robotic arm technology, designed with five degrees of freedom, can grasp objects up to 6 cm wide and weighing less than 500 grams. Combined with a dual-vision system and RGBD camera, this technology has transitioned robots from “passive obstacle avoidance” to “active organization.” In terms of cleaning, smart mop-changing technology allows automatic identification of polluted areas by the base station, enabling dedicated mops for high-risk zones such as kitchens and bathrooms, along with a 100°C hot-wash function that builds a health protection system for the home.

Innovations in hardware are also significant: the X50 enhanced version uses a bionic mechanical foot and active suspension system, capable of overcoming vertical obstacles up to 2.8 cm. The "volcanic lake soaking wash" technology dissolves stubborn stains with high-temperature steam. These breakthroughs raise the bar for circuit stability, especially in core modules such as motor drives and battery management, making electrostatic protection essential for ensuring reliable device operation.

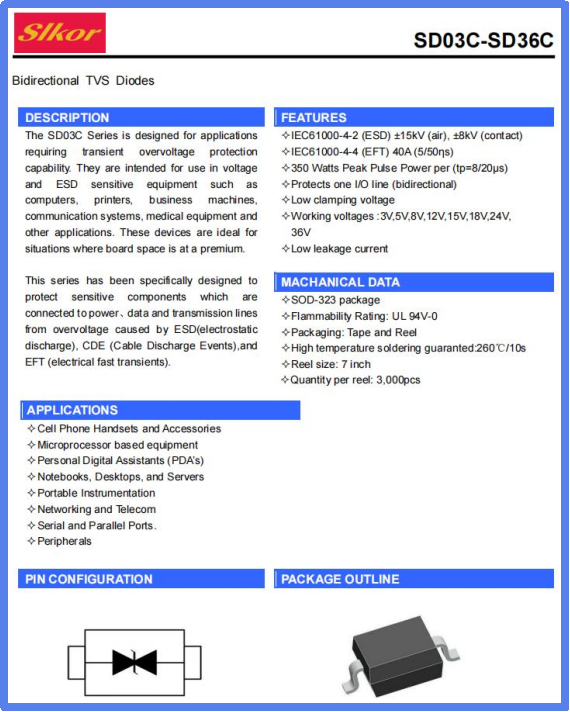

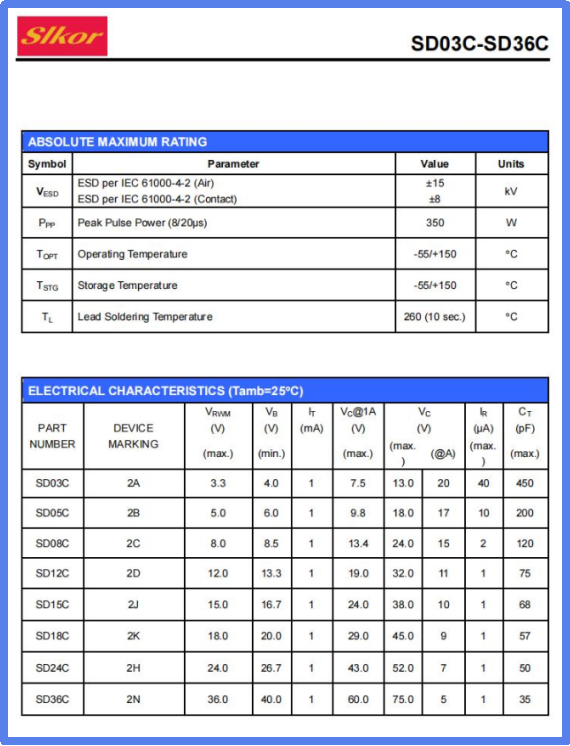

Slkor Electrostatic Discharge Diode SD05C specification

Designed specifically for portable devices, the SD05C ESD protection component has the following core advantages:

1. Precise Protection Capability

- Reverse Working Voltage (VRWM) = 5V, precisely matching the working voltage of the vacuum robot’s main control chip.

- Breakdown Voltage (VBR) = 6V (IT = 1mA), offering controlled voltage clamping during electrostatic surges.

- Peak Pulse Power of 350W (8/20μs waveform), absorbing energy from air discharge up to ±15kV and contact discharge up to ±8kV in accordance with IEC 61000-4-2 standards.

2. Signal Integrity Assurance

- Junction Capacitance (CJ) = 60pF (VR = 0V, f = 1MHz), much lower than similar devices, ensuring distortion-free sensor signal transmission.

- Response Time <1ns, initiating protection instantly upon the arrival of an electrostatic pulse.

3. Space and Energy Efficiency

- SOD-323 package size of just 1.8mm × 1.4mm, ideal for the compact PCB layout of vacuum robots.

- Reverse Leakage Current (IR) = 0.5μA (VRWM = 5V), with annual power consumption below 0.00438Wh, meeting the vacuum robot’s long-lasting standby requirements.

Parameters of Slkor Electrostatic Discharge Diode SD05C

In the design of the Trifo X50 Enhanced version, the SD05C is deployed at three key points:

1. Laser Radar Interface Protection

- The SD05C is connected in parallel to the TTL level interface of the LDS laser navigation module to prevent electrostatic surges from coupling into the main control chip via rotating parts. Tests show that under a ±8kV contact discharge test, the diode can clamp the voltage to under 12V, preventing latch-up effects in the 3.3V MCU.

2. Battery Management System (BMS) Protection

- For the lithium battery pack’s balancing circuit, the SD05C is paired with the SMAJ48A TVS diode for dual protection. When the charging interface encounters an ESD surge, the SD05C absorbs the lower-energy pulses first. If the surge exceeds its limits, the SMAJ48A activates secondary clamping to protect the MOSFET from damage.

3. Motor Drive Circuit Protection

- In the PWM control line of the brushless motor driver, the SD05C forms an RC filter network with a 100Ω series resistor. This design filters out noise from motor start/stop transients while using the diode’s voltage clamping feature to prevent breakdown of the drive chip due to reverse electromotive force. Tests show that under a 30A surge current, the signal distortion in the drive circuit is less than 2%.

Vacuum robots equipped with the SD05C perform excellently in IEC 61000-4-2 standard tests:

- Improved Immunity: Contact discharge tolerance increases from ±4kV to ±8kV, and air discharge tolerance rises from ±8kV to ±15kV.

- Reduced Failure Rates: Production models show that with the SD05C, MCU reset failures due to electrostatic discharge have decreased by 82%.

- Extended Lifespan: In 100,000 charge/discharge cycle tests, the MTBF (Mean Time Between Failures) of the BMS circuit increased by three times.

As GaN power devices are applied in motor drives, circuit operating voltages will continue to decrease, placing higher demands on the response time of protection devices. At the same time, intelligent ESD arrays with self-repairing functions are being developed, capable of real-time monitoring of electrostatic threat levels through built-in sensors and dynamically adjusting the clamping voltage. In the vacuum robot field, this technology will deeply integrate with cutting-edge features such as bionic robotic arms and AI vision, advancing the device towards “self-maintenance.”

Slkor has research and development offices in Busan, South Korea, Beijing, China, and Suzhou, China. Most of the wafer manufacturing and packaging and testing are carried out within China. The company employs and collaborates with individuals and organizations worldwide, with a laboratory for product performance and reliability testing and a central warehouse located at its headquarters in Shenzhen. Slkor has filed for over a hundred invention patents, offers more than 2,000 product models, and serves over ten thousand customers globally. Its products are exported to countries and regions including Europe, the Americas, Southeast Asia, and the Middle East, making it one of the rapidly growing semiconductor companies in recent years. With well-established management systems and streamlined workflows, Slkor has rapidly enhanced the brand awareness and reputation of its "SLKOR" brand through its outstanding quality and standardized services. Its product range includes three major series: diodes, transistors, and power devices, with recent introductions of new products such as Hall elements and analog devices, expanding its presence in sensors, Risc-v microcontrollers, and other product categories.

Site Map | 萨科微 | 金航标 | Slkor | Kinghelm

RU | FR | DE | IT | ES | PT | JA | KO | AR | TR | TH | MS | VI | MG | FA | ZH-TW | HR | BG | SD| GD | SN | SM | PS | LB | KY | KU | HAW | CO | AM | UZ | TG | SU | ST | ML | KK | NY | ZU | YO | TE | TA | SO| PA| NE | MN | MI | LA | LO | KM | KN

| JW | IG | HMN | HA | EO | CEB | BS | BN | UR | HT | KA | EU | AZ | HY | YI |MK | IS | BE | CY | GA | SW | SV | AF | FA | TR | TH | MT | HU | GL | ET | NL | DA | CS | FI | EL | HI | NO | PL | RO | CA | TL | IW | LV | ID | LT | SR | SQ | SL | UK

Copyright ©2015-2025 Shenzhen Slkor Micro Semicon Co., Ltd