Service hotline

+86 0755-83044319

release time:2025-05-13Author source:SlkorBrowse:5856

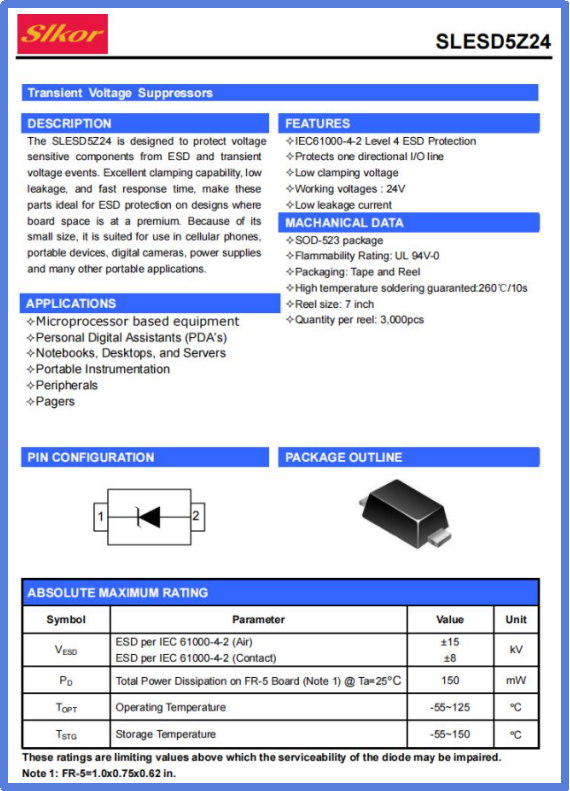

In today's highly integrated electronic devices, electrostatic discharge (ESD) has become a hidden threat to circuit stability. From accidental touch-screen misoperations on smartphones to sudden malfunctions in industrial equipment, ESD events can lead to data loss, component damage, or even system failure. In response, the high-performance electrostatic protection diode — SLESD5Z24 — has been developed.

Slkor Electrostatic Discharge Diode SLESD5Z24 product photo

1. VRWM (Maximum Reverse Working Voltage): 24V

VRWM defines the maximum continuous reverse voltage the device can withstand during normal operation. With a 24V rating, the SLESD5Z24 operates stably in most low-voltage digital circuits (such as 5V and 3.3V systems) while leaving sufficient safety margin for transient overvoltage. This parameter directly determines the device’s application range, preventing false triggering or protection failure due to voltage fluctuations.

2. VBR min (Minimum Breakdown Voltage): 26V

When the voltage exceeds VBR min, the diode enters avalanche breakdown, allowing current to flow to dissipate the electrostatic energy. The 26V minimum breakdown voltage ensures that the SLESD5Z24 remains in a high-impedance state under normal operating voltage (24V), only responding quickly when subjected to an ESD surge. This “precise triggering” feature effectively balances protection sensitivity and system stability.

3. IR (Reverse Leakage Current): 5μA

Leakage current is a key indicator of the device’s static power consumption. With a leakage current of only 5μA at 24V, the SLESD5Z24 has a negligible impact on the circuit during standby or low-power mode. This feature is especially important for battery-powered devices (such as IoT sensors and wearable devices) as it significantly extends battery life.

4. VC (Clamping Voltage): 35V

Clamping voltage represents the maximum voltage the device can limit the electrostatic discharge to during current dissipation. The SLESD5Z24’s 35V clamping voltage is much lower than the breakdown voltage of most semiconductor devices (e.g., MOSFET gate oxide breakdown voltage is usually above 50V), ensuring protection circuits are shielded from secondary overvoltage damage. The difference between VC and VBR (35V-26V = 9V) reflects the device’s dynamic impedance characteristic: the smaller the difference, the better the protection performance.

5. CJ (Junction Capacitance): 50pF

Junction capacitance directly affects signal transmission quality, especially in high-speed interfaces (e.g., USB, HDMI). Excessive capacitance can cause signal distortion. The 50pF junction capacitance of the SLESD5Z24 is relatively low among similar products, allowing compatibility with GHz-level high-frequency signals without introducing signal integrity issues due to the protection device.

6. Package: SOD-523

The SOD-523 is an ultra-small surface-mount package measuring just 1.0mm x 0.6mm x 0.5mm, making it ideal for high-density circuit board designs. Its compact size not only saves space but also reduces parasitic inductance, improving the ESD response speed.

Slkor Electrostatic Discharge Diode SLESD5Z24 specification

Parameters of Slkor Electrostatic Discharge Diode SLESD5Z24

1. Consumer Electronics: Ideal for Slim Design

In portable devices such as smartphones and tablets, the SLESD5Z24’s SOD-523 package can be mounted in tight spaces like USB interfaces or camera modules. Its low junction capacitance ensures stable high-speed data transmission (such as USB 3.0).

2. Automotive Electronics: Withstanding Complex Electromagnetic Environments

Automotive electronic systems need to handle interference from engine ignition and electromagnetic pulses. The SLESD5Z24 operates stably in a wide temperature range from -55°C to +150°C, effectively protecting critical circuits such as CAN bus and sensor interfaces.

3. Industrial Control: Ensuring High Reliability

In devices like PLCs and inverters, the SLESD5Z24's low leakage current design reduces energy loss during long-term operation, while its 35V clamping voltage protects against common electrostatic fast transients (EFT) in industrial environments.

Voltage Matching: Ensure the working voltage of the protected circuit is below VRWM to avoid the device operating in breakdown mode for extended periods.

Capacitance Optimization: For ultra-high-speed interfaces (e.g., above 10Gbps), select a version with lower junction capacitance (e.g., below 10pF).

Layout Design: Place the SLESD5Z24 as close as possible to the protected pins and minimize trace length to reduce parasitic inductance.

With its precise design parameters, compact package size, and comprehensive protection features, the SLESD5Z24 is an ideal solution for electrostatic protection in low-voltage circuits. In the face of the technological waves brought by 5G, IoT, and new energy vehicles, the value of such high-performance protection devices will become increasingly evident. They not only act as a "safety valve" for circuits but also serve as the cornerstone for system reliability. As material science and packaging technologies progress, electrostatic protection diodes will continue to evolve, safeguarding every innovation in the electronic world with even smaller sizes and lower power consumption.

Slkor has research and development offices in Busan, South Korea, Beijing, China, and Suzhou, China. Most of the wafer manufacturing and packaging and testing are carried out within China. The company employs and collaborates with individuals and organizations worldwide, with a laboratory for product performance and reliability testing and a central warehouse located at its headquarters in Shenzhen. Slkor has filed for over a hundred invention patents, offers more than 2,000 product models, and serves over ten thousand customers globally. Its products are exported to countries and regions including Europe, the Americas, Southeast Asia, and the Middle East, making it one of the rapidly growing semiconductor companies in recent years. With well-established management systems and streamlined workflows, Slkor has rapidly enhanced the brand awareness and reputation of its "SLKOR" brand through its outstanding quality and standardized services. Its product range includes three major series: diodes, transistors, and power devices, with recent introductions of new products such as Hall elements and analog devices, expanding its presence in sensors, Risc-v microcontrollers, and other product categories.

Site Map | 萨科微 | 金航标 | Slkor | Kinghelm

RU | FR | DE | IT | ES | PT | JA | KO | AR | TR | TH | MS | VI | MG | FA | ZH-TW | HR | BG | SD| GD | SN | SM | PS | LB | KY | KU | HAW | CO | AM | UZ | TG | SU | ST | ML | KK | NY | ZU | YO | TE | TA | SO| PA| NE | MN | MI | LA | LO | KM | KN

| JW | IG | HMN | HA | EO | CEB | BS | BN | UR | HT | KA | EU | AZ | HY | YI |MK | IS | BE | CY | GA | SW | SV | AF | FA | TR | TH | MT | HU | GL | ET | NL | DA | CS | FI | EL | HI | NO | PL | RO | CA | TL | IW | LV | ID | LT | SR | SQ | SL | UK

Copyright ©2015-2025 Shenzhen Slkor Micro Semicon Co., Ltd