Service hotline

+86 0755-83044319

release time:2025-05-06Author source:SlkorBrowse:1313

In the fast-evolving field of robotics, from industrial robotic arms to service robots, the reliability of electronic systems directly determines the operational efficiency and lifespan of the equipment. Electrostatic discharge (ESD), a common hazard for electronic devices, can generate transient high voltages through human contact, device friction, or environmental interference, causing irreversible damage to the core circuits of robots. Shenzhen Slkor Co., Ltd. has launched the SLESDL0603-16 ESD protection diode, which, with its ultra-low capacitance, high voltage tolerance, and miniaturized design, has become a critical component for safeguarding robotic electronic systems.

Slkor Transient Protection Diode SLESDL0603-16 product photo

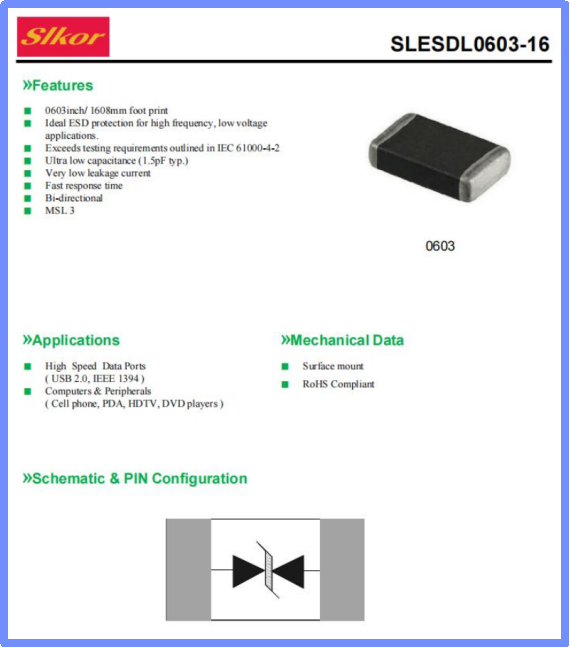

Ultra-low Capacitance Design Ensures Signal Integrity

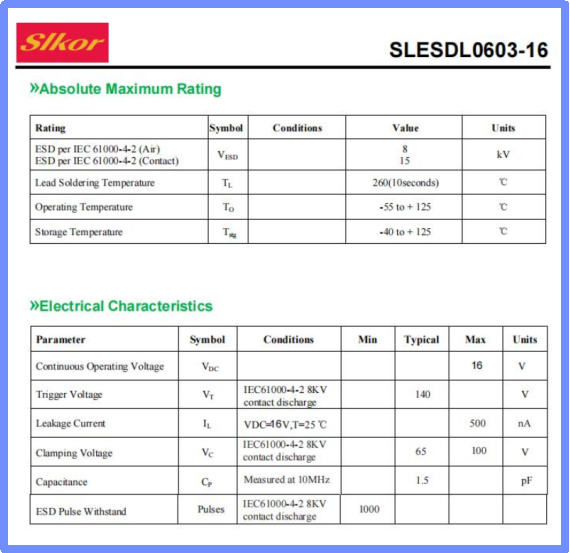

The junction capacitance of the SLESDL0603-16 is just 1.5pF, significantly lower than the average of similar products. In robot sensor interfaces (such as lidar and IMU modules), high-frequency signal transmission is extremely sensitive to parasitic capacitance. For instance, in industrial robotic joint control, using an ESD device with capacitance over 5pF can lead to phase shifts in encoder signals, resulting in motion control errors. The low capacitance of this device ensures sharp signal rise and fall times, preventing positioning accuracy degradation due to signal distortion.

Slkor Transient Protection Diode SLESDL0603-16 specification

Wide Voltage Operating Range to Adapt to Various Scenarios

With a reverse working voltage (VRWM) of 16V, the SLESDL0603-16 can cover the common supply voltage ranges for robots. For example, in collaborative robots, the end-effector motor driver circuits typically use 12V or 24V power, and the VRWM of the SLESDL0603-16 exceeds the system voltage, ensuring that the leakage current remains below 500nA under normal working conditions, without significantly increasing power consumption. Additionally, its clamping voltage (VC) of 100V allows it to withstand ±15kV contact discharge as per IEC 61000-4-2 standards, effectively protecting against electrostatic shocks caused by human contact or device friction.

Parameters of Slkor Transient Protection Diode SLESDL0603-16

Miniaturized Packaging for High-Density PCB Designs

With a 0603 package size (1.6mm×0.8mm), the SLESDL0603-16 is an ideal choice for robotic PCB designs. In service robot head modules, sensor arrays and communication interfaces are densely arranged, and traditional SOT-23 packaged components occupy more than three times the space of 0603 packaged components. The use of SLESDL0603-16 can free up around 70% of PCB area, providing more layout space for algorithm chips or power modules while reducing the risk of thermal coupling.

Industrial Robot Joint Control Protection

In automotive welding robots, the encoders and servo driver interfaces at the arm joints are frequently exposed to electrostatic charges generated by metal friction. The bidirectional conduction property of the SLESDL0603-16 protects against both positive and negative voltage shocks, making it compatible with the differential signal transmission requirements of servo drivers.

Service Robot Interactive Interface Protection

Commercial cleaning robots' touchscreens and charging contacts are highly susceptible to electrostatic discharges from user interactions. A certain model of robot experienced frequent touchscreen failure due to static discharges. The SLESDL0603-16, when connected in parallel between the USB-C interface and ground, provides ±8kV contact discharge protection, extending the touchscreen module's lifespan by more than three times.

Outdoor Robot Environmental Adaptability Enhancement

Agricultural inspection robots operating in dusty and humid environments face a 40% higher rate of electrostatic events compared to indoor settings. The SLESDL0603-16’s 100V clamping voltage protects against transient high voltages caused by sand and dust friction, and its operating temperature range of -40°C to 125°C ensures stable performance even in extreme weather conditions.

|

Specification |

SLESDL0603-16 |

Traditional TVS Diode |

Varistor (MOV) |

|

Response Time |

<1ns |

1-5ns |

25-100ns |

|

Impact Resistance |

Thousands (IEC standard) |

Hundreds |

Dozens (performance degradation) |

|

Package Size |

0603 (1.6×0.8mm) |

SOT-23 (3×1.4mm) |

DO-214AC (5.3×3.6mm) |

|

Suitable Signal Type |

High-speed/low-frequency fully compatible |

Medium-speed |

Low-frequency |

In robotic vision systems, traditional MOVs suffer from high capacitance (>100pF), causing HDMI signal attenuation, while the SLESDL0603-16 ensures a capacitance matching of <1pF, guaranteeing undistorted 4K video transmission.

According to statistics, the annual global loss in robotic electronic systems due to ESD will exceed $2 billion by 2025. The SLESDL0603-16 enhances the mean time between failures (MTBF) of robots by 2-3 times through optimized packaging, capacitance, and voltage tolerance parameters. In the field of medical robotics, its low leakage current (<500nA) avoids interference with biological sensors such as ECG electrodes, ensuring surgical precision.

Looking ahead, as robots continue to evolve towards smaller sizes and higher integration, the 0201 package version of the SLESDL0603-16 is already under development, with junction capacitance expected to decrease further to below 0.5pF. From industrial production lines to home service, this "invisible guardian" will continue to strengthen the safety barrier for robotic electronic systems.

Slkor has research and development offices in Busan, South Korea, Beijing, China, and Suzhou, China. Most of the wafer manufacturing and packaging and testing are carried out within China. The company employs and collaborates with individuals and organizations worldwide, with a laboratory for product performance and reliability testing and a central warehouse located at its headquarters in Shenzhen. Slkor has filed for over a hundred invention patents, offers more than 2,000 product models, and serves over ten thousand customers globally. Its products are exported to countries and regions including Europe, the Americas, Southeast Asia, and the Middle East, making it one of the rapidly growing semiconductor companies in recent years. With well-established management systems and streamlined workflows, Slkor has rapidly enhanced the brand awareness and reputation of its "SLKOR" brand through its outstanding quality and standardized services. Its product range includes three major series: diodes, transistors, and power devices, with recent introductions of new products such as Hall elements and analog devices, expanding its presence in sensors, Risc-v microcontrollers, and other product categories.

Site Map | 萨科微 | 金航标 | Slkor | Kinghelm

RU | FR | DE | IT | ES | PT | JA | KO | AR | TR | TH | MS | VI | MG | FA | ZH-TW | HR | BG | SD| GD | SN | SM | PS | LB | KY | KU | HAW | CO | AM | UZ | TG | SU | ST | ML | KK | NY | ZU | YO | TE | TA | SO| PA| NE | MN | MI | LA | LO | KM | KN

| JW | IG | HMN | HA | EO | CEB | BS | BN | UR | HT | KA | EU | AZ | HY | YI |MK | IS | BE | CY | GA | SW | SV | AF | FA | TR | TH | MT | HU | GL | ET | NL | DA | CS | FI | EL | HI | NO | PL | RO | CA | TL | IW | LV | ID | LT | SR | SQ | SL | UK

Copyright ©2015-2025 Shenzhen Slkor Micro Semicon Co., Ltd